Synergy – Tank Surveillance Module 3110-021

SERVICE BULLETIN SB 3077 Rev. A 3/12

Balcrank Corporation, Inc.

9

is current based. The shield can be used for protection grounding purposes if needed.

Observe!

– It is important that the transparent tube is not blocked and that the humidity protection

filter is used.

A blocked tube will cause measuring failure.

Not using the humidity protection could cause sensor malfunction due to corrosion caused

by condensed water.

Observe! To use analogue sensors a Synergy keypad (23401) or LED (23404) is needed to show the

tank volume.

9. Technical specification

Net ports:

5 Synergy ports

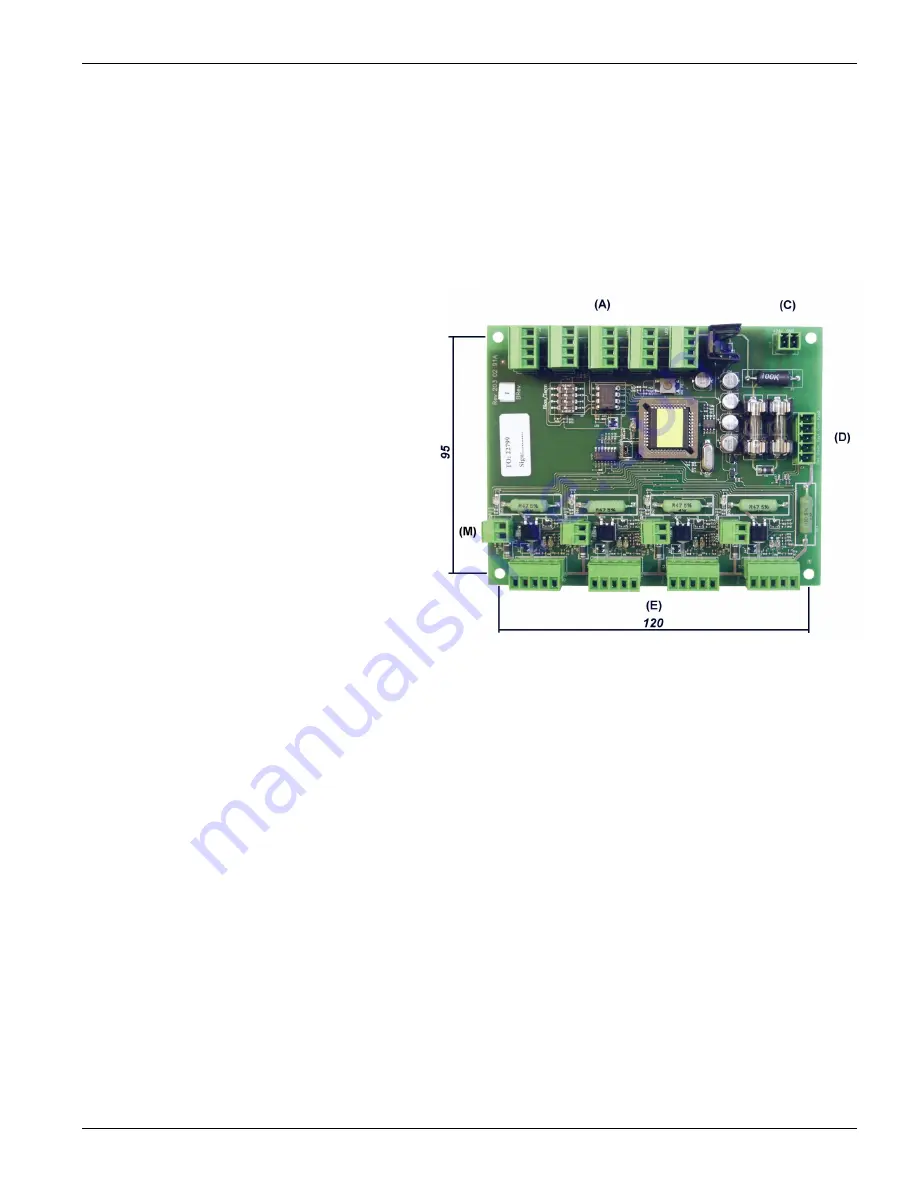

(A)

for data

communication, 2

w24VDC.

Discrete level inputs:4

(E),

for one or two levels. Switch or active signal max 50 V. Supports reorder and stop set-up for both fresh and waste oil.

Analogue level inputs: ....................................... 4

(M)

4 - 20mA, 24VDC with 10-bit A/D-converters.

Control outputs: 4

(E)

for solenoid

valve 24 VDC max

1,25 A. Closes after

about 30 s when

short circuited, this

is logged in the

database.

Other:

RISC-based

microprocessor

EEPROM, 64 KB.

Connector

(D)

for 3-

pos key switch.

Connector

(C)

for 24

VDC 5A power supply.

SetupLock jumper

(F)

, not used.

Power supply:

Primary 230 VAC 500mA

Secondary 24 VDC 5 A

Max current:

500 mA + 4x1.25 A for solenoid valves

Casing:

Strong black powder painted steel box

Outer measures: 303 x 228 x 65 mm.

Fitting:

4 x ø5mm

CC = 250 x 175 mm

Weight:

3,9 kg