Summary of Contents for CRI-A

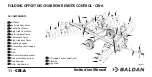

Page 1: ...Folding Offset Disc Harrow Remote Control CRI A...

Page 2: ......

Page 4: ...Folding Offset Disc Harrow Remote Control CRI A...

Page 61: ...InstructionManual 59 CRI A 13 NOTES...

Page 64: ......

Page 66: ......

Page 68: ......

Page 70: ......

Page 71: ......