Instruction Manual

53 -

CRI-A

01 -

01 -

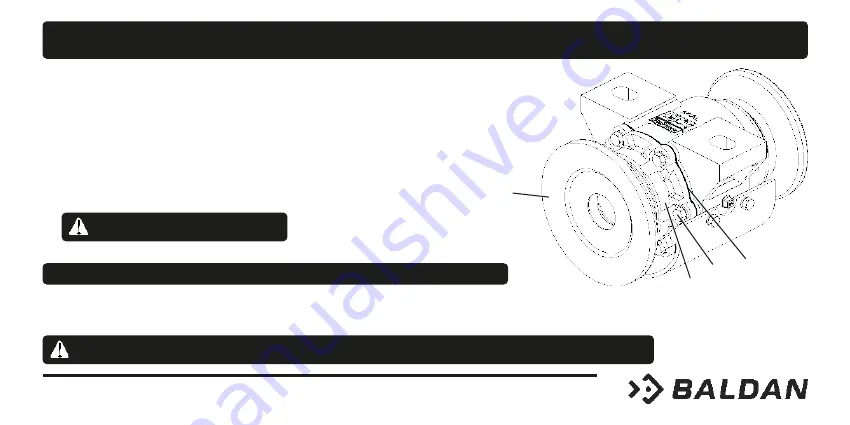

Remove the washer (1).

02 -

02 -

Then loosen the bolts (2) and remove the cover from the bearing (3).

03 -

03 -

After, remove one or two joints (4) from the bearing cover (3). Put back the bearing co-

ver (3) and retighten.

04 -

04 -

If the slackness persists, face the bearing cover (3) to increase the adjust, and then mou-

ntit on the bearing with as many joints considered necessary.

05 -

05 -

The bearing should rotate freely without slacks.

1

4

2

3

BEARING ADJUSTMENTS (FIGURE 36)

CRI -A 40 / 44 / 48 DISCS

Figure 36

Do not mount the bearing without joints (4).

BEARING LUBRICATION

01 -

01 -

On the rst days of work with the CRI-A, check the oil level of the bearings daily and then check it after every 120 hours of work.

02 -

02 -

The oil should be changed after every 1200 hours of work. Use oil for transmission 90 API GL4, MIL-L-2105; SAEJ306, May/81; SAE 80W,90 and 140.

•

•

When the bearings become slack, proceed as follows to adjust them:

The ideal oil level is the level at which it reaches the hole of the plug. Find a at place when checking the oil level of bearing.

Summary of Contents for CRI-A

Page 1: ...Folding Offset Disc Harrow Remote Control CRI A...

Page 2: ......

Page 4: ...Folding Offset Disc Harrow Remote Control CRI A...

Page 61: ...InstructionManual 59 CRI A 13 NOTES...

Page 64: ......

Page 66: ......

Page 68: ......

Page 70: ......

Page 71: ......