Installation & Operation 2-5

MN409

Coupled Start Up

This procedure assumes a coupled start up. Also, that the first time start up procedure was

successful. Read and fully understand each of the steps in the following procedure before attempting to

start the motor.

1.

Disconnect and lockout the power source. Ensure no power is applied to the motor.

2.

After a successful uncoupled start, assemble the coupling and lubricate with the manufacturer’s

recommended lubricant. Check to see that the coupling is not binding.

3.

After the coupling has been assembled and lubricated, repeat steps 11 through 14 under First Time

Start Up. Check to see that the driven equipment is not transmitting vibration back to the motor

through the coupling or the base.

4.

Check to see that coupling guards and other protective enclosures are not blocking the ventilating air

over the motor and exhaust openings.

5.

When alignment is correct and motor is properly lubricated, prepare for no load run uncoupled

start

−

up. The coupling should be uncoupled and a solo plate should be installed if required.

6.

Inspect the motor carefully. Make the initial start by following the regular sequence of starting

operations in the control instructions.

7.

After starting, check that the motor is running smoothly. If the motor shows excessive vibration, shut

down immediately and investigate. Check for coupling and key unbalance, lack of lubrication, foot

planarity and structural resonance.

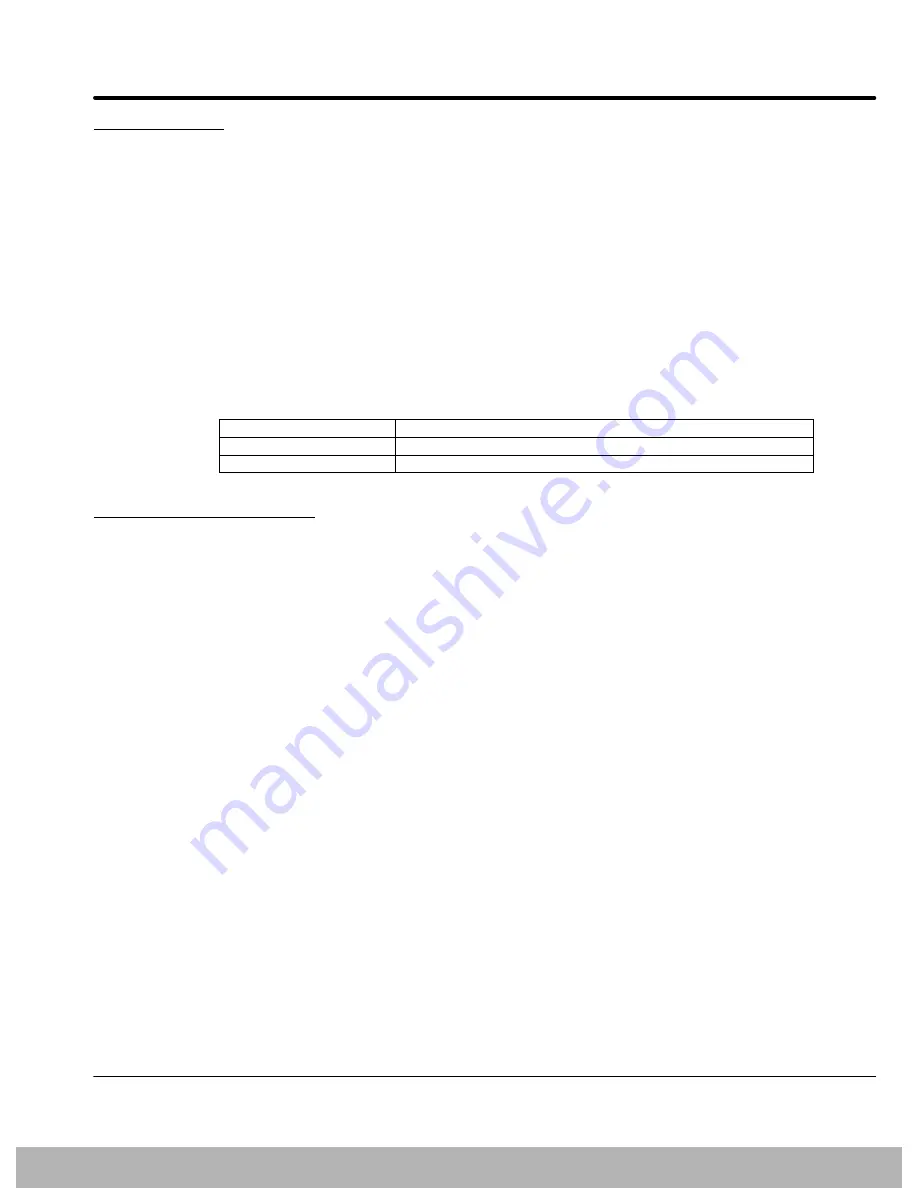

RPM

Max. Vibration Amplitude (Peak to Peak on Bearing Housing)

3000

−

3600 Incl.

.75 mil (.20 in/sec peak)

1800

−

Slower

1.0 mil (.20 in/sec peak)

Jogging and Repeated Starts

Repeated starts and/or jogs can greatly reduce the life of an induction motor. If it is necessary to

repeatedly start or jog a motor, check the application with your local Baldor District office.

At ambient temperature, the motor is normally capable of making two starts in succession and coasting to

rest between starts.

The motor is also capable of making one start at its rated load operation temperature. For cooling time

required before additional starts can be made consult your local Baldor District office or the motor starting

nameplate if one is provided.

If more starts than defined above are attempted in shorter period of time, severe damage to the motor

electrical windings and rotor may result.

The starting conditions listed above apply only if the inertia of the connected load, the load torque during

acceleration, the applied voltage, and the starting method are those for which the motor was designed.

For starting situations not covered here, consult your local Baldor District office before proceeding. Refer

also to the motor nameplate which may list starting conditions.

This Manual:http://www.manuallib.com/baldor/mn409-large-ac-motors-handbook.html