3-24 Receiving and Installation

MN715J

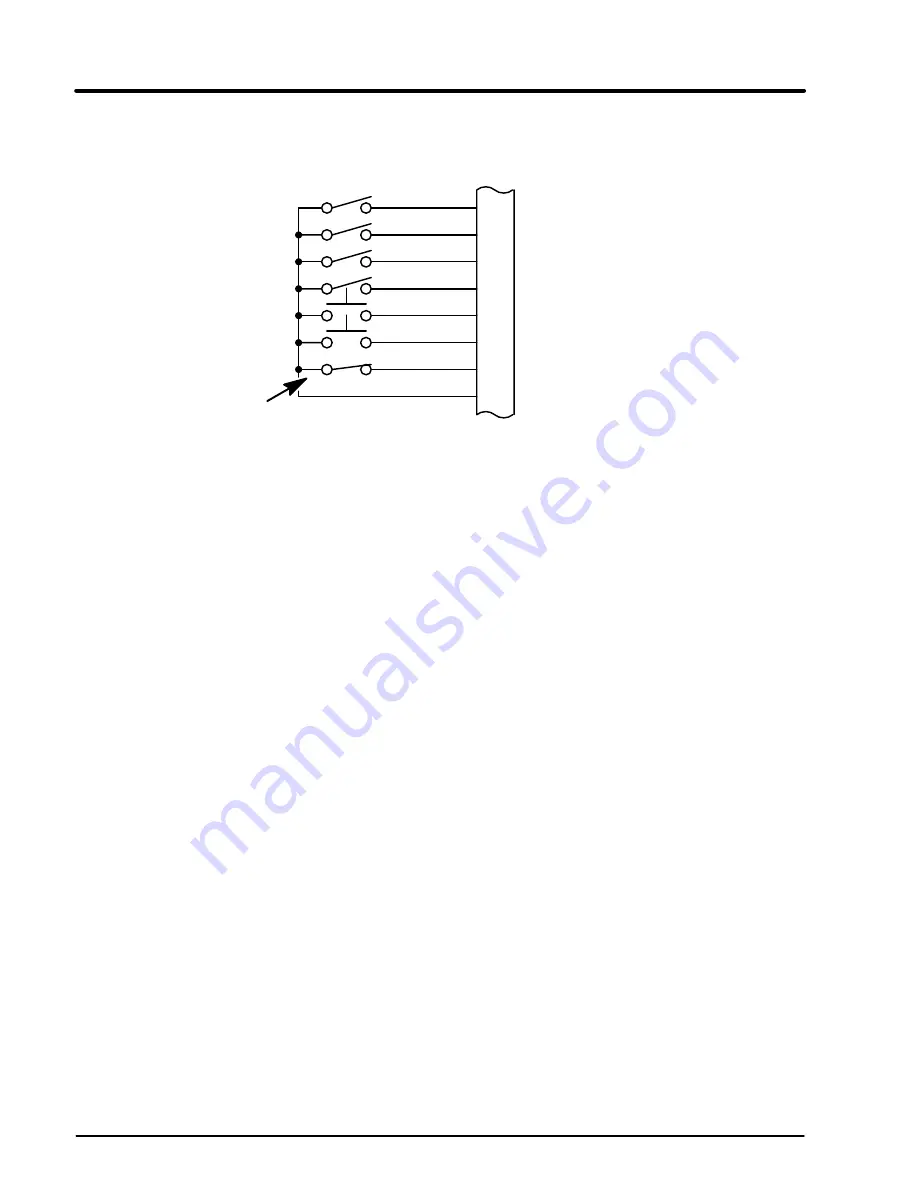

EPOT 2 Wire Connection

Figure 3-18 Electronic POT 2 Wire Connection Diagram

11

12

13

14

15

16

17

18

Forward

Reverse

EPOT/CMD Select

Accel/Decel Select

Increase

Decrease

External Trip

Input Common

Refer to Figure 3Ć9.

J4

See recommended terminal

tightening torques in Section 6.

J4-11

OPEN motor decels to stop (depending on Keypad Stop mode).

CLOSED to enable operation in the Forward direction.

J4-12

OPEN motor decels to stop (depending on Keypad Stop mode).

CLOSED to enable operation in the Reverse direction.

J4-13

OPEN for normal speed mode. Terminal strip speed source is selected in the

Level 1 Input block, ANA CMD Select parameter.

CLOSED to enable the Electronic Potentiometer Mode.

J4-14

OPEN selects ACC / DEC / S-CURVE group 1.

CLOSED selects group 2.

J4-15

Momentary CLOSED increases motor speed while closed.

J4-16

Momentary CLOSED decreases motor speed while closed.

J4-17

If J4-17 is connected, you must set Level 2 Protection block, External Trip to

“ON” to activate the opto input.

OPEN causes an external trip fault. The control will disable and the motor

coasts to a stop. An external trip fault is displayed (also logged in the fault log).

CLOSED allows normal operation.

Summary of Contents for ID15J101-ER

Page 1: ...Series 15J Inverter Control 7 04 MN715J Installation and Operating Manual ...

Page 5: ...iv Table of Contents MN715J ...

Page 11: ...2 4 General Information MN715J ...

Page 59: ...4 22 Programming and Operation MN715J ...

Page 75: ...6 6 Specifications and Product Data MN715J ...

Page 79: ...A 4 Dynamic Brake Hardware MN715J ...

Page 86: ...Appendix C Remote Keypad Mounting Template MN715J Remote Keypad Mounting Template C 1 ...