5-8 Troubleshooting

MN715J

Table 5-2 Troubleshooting

Continued

INDICATION

POSSIBLE

CAUSE

CORRECTIVE ACTION

Motor Will

Not Reach

M i

Max Frequency

Limit set too low.

Adjust Max Frequency Limit parameter value.

Not Reach

Maximum

Speed

Motor overloaded. Check for mechanical overload. If unloaded motor shaft does

not rotate freely, check motor bearings.

p

Improper speed

command.

Verify control is receiving proper command signal at input

terminals.

Verify control is set to proper operating mode to receive your

speed command.

Speed

potentiometer

failure.

Replace potentiometer.

Motor will not

stop rotation

MIN Output

Speed parameter

set too high.

Adjust MIN Output Speed parameter value.

Improper speed

command.

Verify control is receiving proper command signal at input

terminals.

Verify control is set to receive your speed command.

Speed

potentiometer

failure.

Replace potentiometer.

Motor runs

rough at low

Torque boost set

too high.

Adjust torque boost parameter value.

rough at low

speed

Misalignment of

coupling.

Check motor/load coupling alignment.

Faulty motor.

Replace with a Baldor Motor.

Regen RES

Power

Incorrect dynamic

brake parameter.

Check Resistor Ohms and Resistor Watts parameters in the

Level 2 Brake Adjust block.

Power

Regen power

exceeded resistor

rating.

Use resistor with a larger power rating.

Increase Decel Time.

Comm

Timeout

Communication

failure between

keypad and motor

control.

Verify connections of all signals and grounds.

Press “RESET” key on keypad. If fault remains, contact Baldor.

Software

VER FLT

Keypad and

control software

versions are

incompatible.

Press “RESET” key on keypad.

Reset power.

If fault remains, contact Baldor.

3 SEC

Overload

*

Output current

exceeded 3

second rating.

Verify motor rated amperes parameter matches FLA of motor.

Verify proper sizing of control and motor.

If error occurred while ramping motor, check motor, coupling and

l d

1 MIN

Overload

*

Output current

exceeded 1

minute rating.

If error occurred while ramping motor, check motor, coupling and

load.

Increase ACCEL time.

Increase/Decrease Torque Boost value.

*

Note: An overload fault cannot be reset (cleared) until the “% OVERLOAD LEFT”

counter reaches 100%.

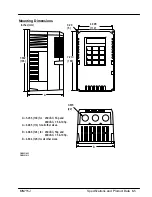

Summary of Contents for ID15J101-ER

Page 1: ...Series 15J Inverter Control 7 04 MN715J Installation and Operating Manual ...

Page 5: ...iv Table of Contents MN715J ...

Page 11: ...2 4 General Information MN715J ...

Page 59: ...4 22 Programming and Operation MN715J ...

Page 75: ...6 6 Specifications and Product Data MN715J ...

Page 79: ...A 4 Dynamic Brake Hardware MN715J ...

Page 86: ...Appendix C Remote Keypad Mounting Template MN715J Remote Keypad Mounting Template C 1 ...