3-4 Receiving & Installation

MN2412

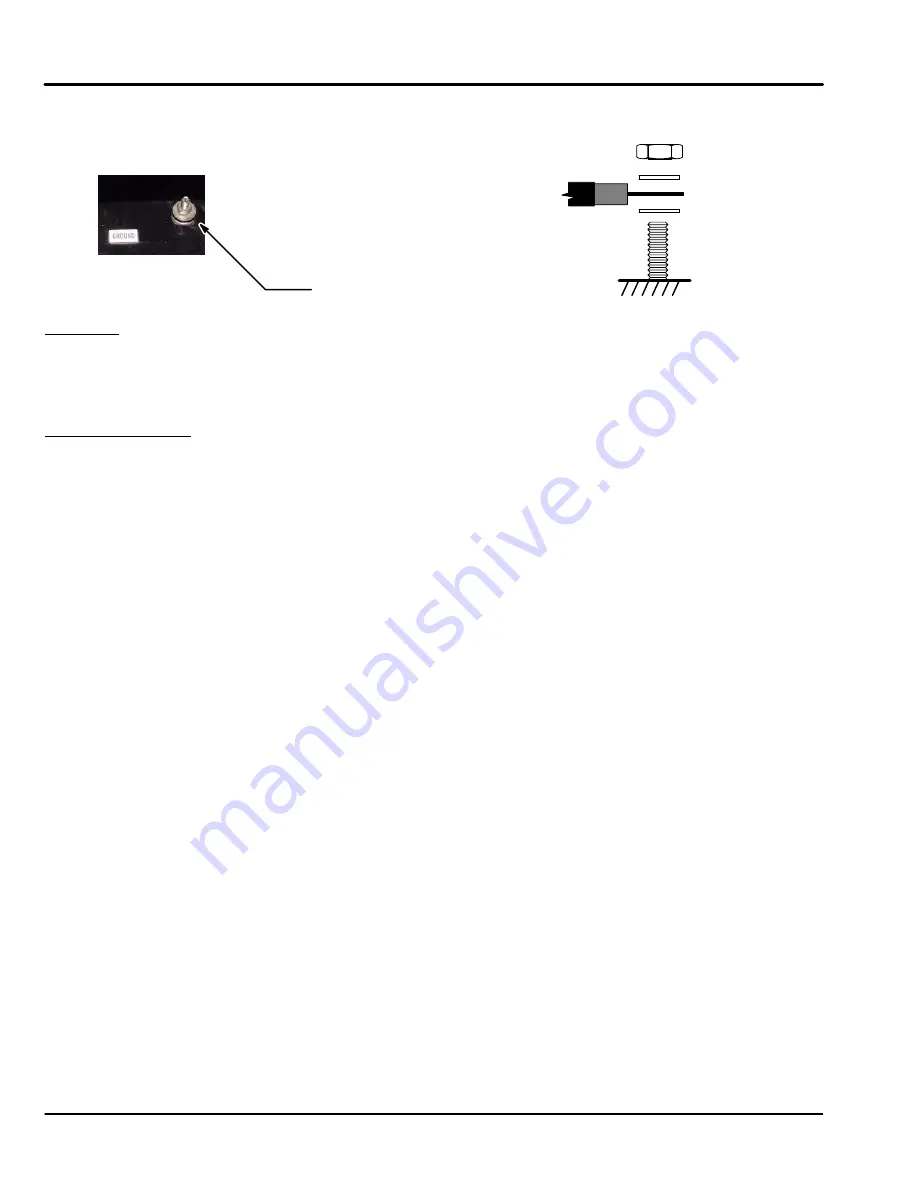

Frame Ground Connection

Continued

Figure 3-3 Frame Ground Connection

Earth Ground

Frame

Stud

Washer

Ground Wire Lug

Nut

Washer

Engine Oil

Refer to the engine manual that was provided with your generator. Determine the correct type of

engine oil and the amount specified by the engine manufacturer. Add the required amount of oil

to bring the oil level to full.

Caution:

The PC90VE generator must have a battery installed for operation. The battery is used during

starting and during operation. If engine operation is attempted while the battery is removed,

damage to the engine’s electrical components may result.

Battery Connections

Applies to 12VDC Electric Start models only. The generator is shipped with no battery installed.

Note: PC90VE units that have an electronic governor must have a battery installed before the

Genset can be started (even with the pull starter). If no battery is present or the battery is

discharged, the electronic governor will not operate and the generator set will not run.

WARNING: Do not dispose of battery or batteries in a fire. The battery is capable of exploding. If the

battery explodes, electrolyte solution will be released in all directions. Battery electrolyte

solution is caustic and can cause severe burns and blindness. If electrolyte contacts skin or

eyes, immediately flush the area with water and seek medical attention quickly.

WARNING: Do not mutilate the battery . The battery contains electrolyte solution which is caustic and

can cause severe burns and blindness. If electrolyte contacts skin or eyes, immediately flush

the area with water and seek medical attention quickly.

WARNING: A battery presents a risk of electrical shock hazard and high short circuit current. The

following precautions are to be followed when working on batteries:

1.

Remove watches, rings, necklaces and all other metal objects.

2.

Use tools with insulated handles.

3.

Wear rubber gloves and boots.

WARNING: The battery electrolyte is a dilute sulfuric acid that is harmful to the skin and eyes. It is

electrically conductive and corrosive. The following precautions are to be followed when

working on batteries:

1.

Wear full eye protection (safety glasses or goggles) and protective clothing.

2.

Where electrolyte contacts the skin, flush the area immediately with water and wash it

off using soap and water.

3.

Where electrolyte contacts the eyes, immediately flush the eye thoroughly with water

and seek medical attention quickly.

4.

Spilled electrolyte is to be washed down with an acid neutralizing agent. A common

practice is to use a solution of one pound (500 grams) bicarbonate of soda to one

gallon (four liters) of water. the bicarbonate solution is to be added until evidence of

reaction (foaming) has ceased. The resulting liquid is to be flushed with water and the

area dried.

WARNING: A battery presents a risk of fire because they generate hydrogen gas. Hydrogen gas is

extremely explosive. Never jump start a battery, smoke in the area around the battery or

cause any spark to occur in the area around the battery. The following precautions are to be

followed when working on batteries:

1.

Do not smoke when near batteries.

2.

Do not cause flame or spark in battery area.

3.

Discharge static electricity from body before touching batteries by first touching a

grounded metal surface.

Summary of Contents for PC Series

Page 1: ...PowerchiefR POW R Products Generator Series PC Installation Operating Manual 5 05 MN2412...

Page 4: ...ii Table of Contents MN2412...

Page 26: ...A 4 PowerchiefR Series MN2412 Figure A 5 PC30H Wiring Diagram...

Page 27: ...PowerchiefR Series A 5 MN2412 Figure A 6 PC40H Wiring Diagram...

Page 28: ...A 6 PowerchiefR Series MN2412 Figure A 7 PC50H Wiring Diagram...

Page 29: ...PowerchiefR Series A 7 MN2412 Figure A 8 PC60H Wiring Diagram...

Page 30: ...A 8 PowerchiefR Series MN2412 Figure A 9 PC90VE Wiring Diagram...