Receiving & Installation 3-5

MN2412

Battery Connections

Continued

Note: PC90VE units that have an electronic governor must have a battery installed before the

Genset can be started (even with the pull starter). If no battery is present or the battery is

discharged, the electronic governor will not operate and the generator set will not run.

Procedure:

The correct type battery must be purchased and installed in the battery compartment provided.

1.

Remove the bag containing the battery box components.

2.

Set the battery on the battery tray.

3.

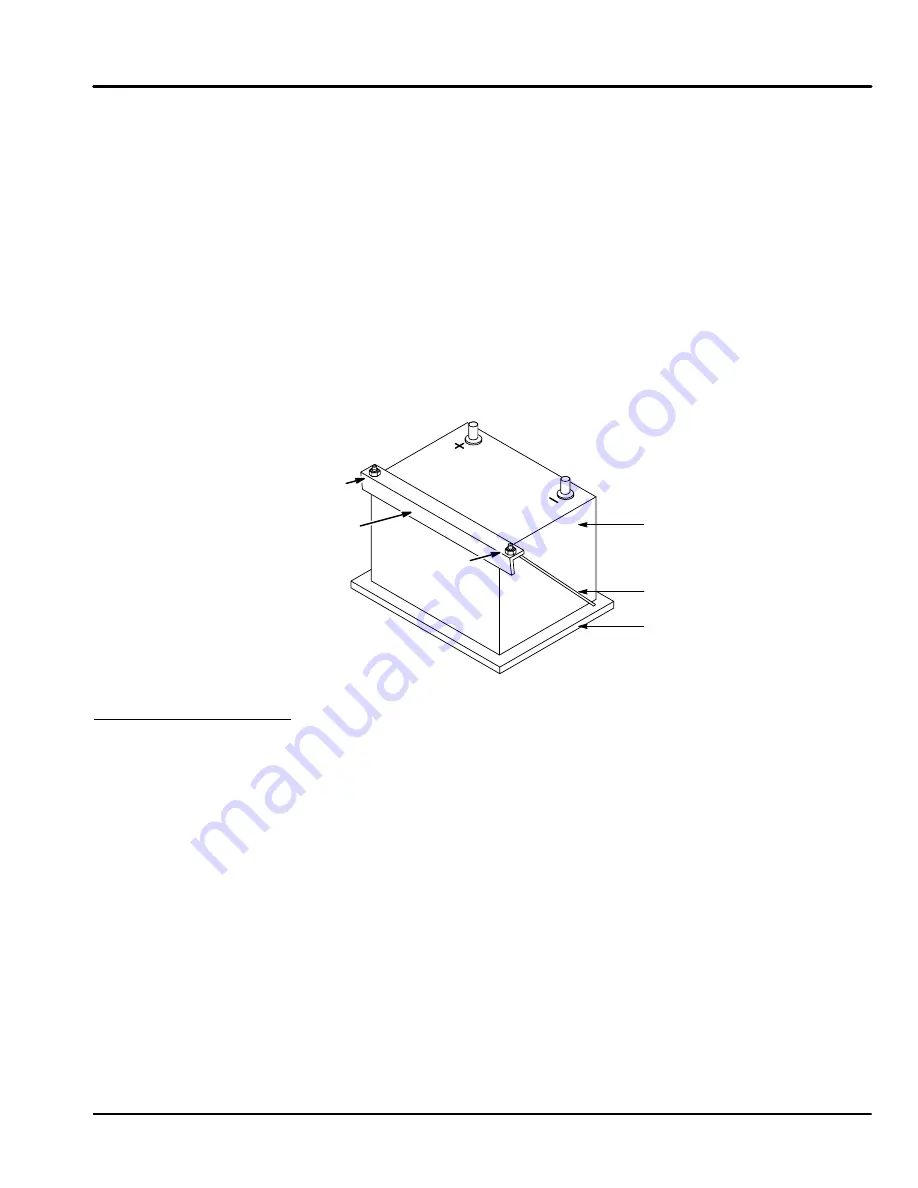

Install the battery hold down rods as shown in Figure 3-4.

a.

Place the bent end of the battery hold down rod through the hole in the battery

tray.

b.

Place the threaded end of the battery hold down rod through the hole in the

battery hold down bar and secure with flat washer, lock washer and nut.

c.

Repeat steps a and b for the other battery hold down rod.

4.

Connect the battery cables to the battery, be sure the Positive lead is connected to the

positive (+) battery terminal and the negative lead is connected to the positive (

−

)

battery terminal.

Figure 3-4 Battery Installation

Washers & Nut

Battery

Battery Tie Down Bolt

Washers & Nut

Battery Rack

Battery Tie Down

The + and

−

terminals of your battery may

be different than shown. Be sure that the

Positive lead is connected to the positive

(+) terminal of your battery.

Use of Electric Motor Loads

Electric motors require much more current (amperes) to start them than to keep them running.

Some motors, particularly split

−

phase motors are very difficult to start and require 5 to 7 times

more current to start them. Repulsion

−

induction type motors are the easiest to start and normally

only require 2 to 3 times as much current to start them.

Most fractional horsepower motors take about the same amount of current to start them and

keep them running. This is true whether they are the repulsion

−

induction type motor, capacitor

type motor, or the split

−

phase type motor.

Other factors that influence the amount of current needed to start a motor are:

1.

The type of load connected to the motor

. If the electric motor is connected to a hard

starting load such as an air compressor it will require more starting current. If the same

electric motor is connected to a light load such as a heater or power saw it will require

less starting current.

2.

The brand or design of the electric motor

. The expected starting current for a

particular size motor will vary depending on the brand of the electric motor as well as

the type of electric motor (Split Phase, capacitor, Repulsion

−

induction type, etc.)

3.

The condition of the electric motor

. A clean motor with free turning bearings will

require less starting currents than a similar type motor that is dirty and the bearings are

not as free turning as they used to be.

Summary of Contents for PC Series

Page 1: ...PowerchiefR POW R Products Generator Series PC Installation Operating Manual 5 05 MN2412...

Page 4: ...ii Table of Contents MN2412...

Page 26: ...A 4 PowerchiefR Series MN2412 Figure A 5 PC30H Wiring Diagram...

Page 27: ...PowerchiefR Series A 5 MN2412 Figure A 6 PC40H Wiring Diagram...

Page 28: ...A 6 PowerchiefR Series MN2412 Figure A 7 PC50H Wiring Diagram...

Page 29: ...PowerchiefR Series A 7 MN2412 Figure A 8 PC60H Wiring Diagram...

Page 30: ...A 8 PowerchiefR Series MN2412 Figure A 9 PC90VE Wiring Diagram...