3-2 Maintenance & Troubleshooting

MN605

Lubrication & Bearings

Bearing grease will lose its lubricating ability over time, not suddenly. The lubricating ability

of a grease (over time) depends primarily on the type of grease, the size of the bearing, the speed at

which the bearing operates and the severity of the operating conditions. Good results can be obtained if

the following recommendations are used in your maintenance program.

Type of Grease

A high grade ball or roller bearing grease should be used. Recommended grease for standard

service conditions is Polyrex EM (Mobil).

Equivalent and compatible greases include:

Texaco Polystar, Rykon Premium #2, Pennzoil Pen 2 Lube and Chevron SRI

−

2.

−

Maximum operating temperature for standard motors = 110

°

C.

−

Shut

−

down temperature in case of a malfunction = 115

°

C.

Lubrication Intervals

Recommended lubrication intervals are shown in Table 3-2. It is important to realize that the

recommended intervals of Table 3-2 are based on average use.

Refer to additional information contained in Tables 3-3 and 3-4.

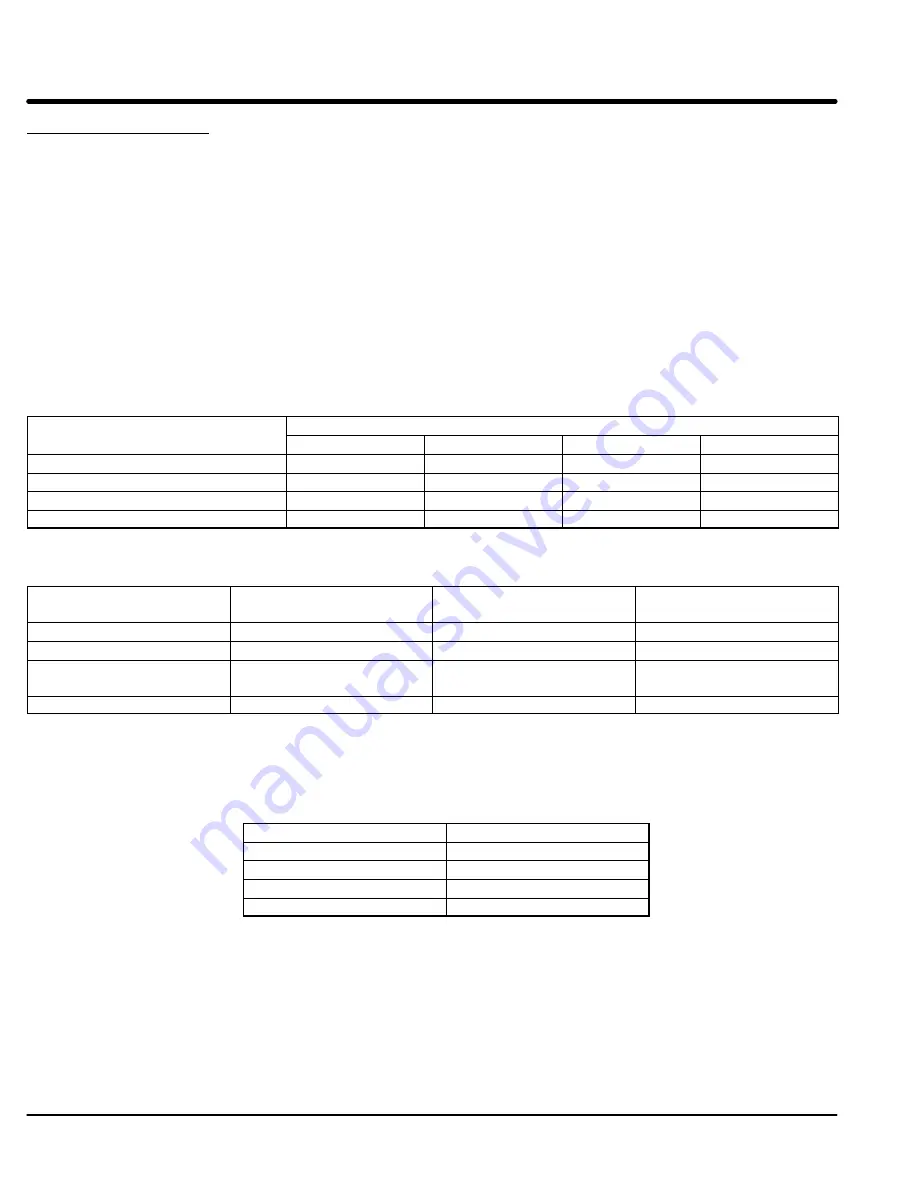

Table 3-2 Lubrication Intervals *

NEMA / (IEC) Frame Size

Base Speed - RPM

>2500

1750

1150

<800

Up to 210 incl. (132)

5500 Hrs.

12000 Hrs.

18000 Hrs.

22000 Hrs.

Over 210 to 280 incl. (180)

3600 Hrs.

9500 Hrs.

15000 Hrs.

18000 Hrs.

Over 280 to 360 incl. (225)

* 2200 Hrs.

7400 Hrs.

12000 Hrs.

15000 Hrs.

Over 360 to 500 incl. (300)

*2200 Hrs.

3500 Hrs.

7400 Hrs.

10500 Hrs.

* Lubrication intervals are for ball bearings. For roller bearings, divide the listed lubrication interval by 2.

Table 3-3 Service Conditions

Severity of Service

Ambient Temperature

Maximum

Atmospheric

Contamination

Type of Bearing

Standard

40

°

C

Clean, Little Corrosion

Deep Groove Ball Bearing

Severe

50

°

C

Moderate dirt, Corrosion

Ball Thrust, Roller

Extreme

>50

°

C* or

Class H Insulation

Severe dirt, Abrasive dust,

Corrosion

All Bearings

Low Temperature

<-30

°

C **

All Bearings

*

Special high temperature grease is recommended (Dow Corning DC44). Note that Dow Corning DC44 grease does

not mix with other grease types. Thoroughly clean bearing & cavity before adding grease.

** Special low temperature grease is recommended (Aeroshell 7). Different brushes may also be required.

Contact your local Baldor district office or an authorized Baldor service center for technical assistance.

Table 3-4 Lubrication Interval Multiplier

Severity of Service

Multiplier

Standard

1.0

Severe

0.5

Extreme

0.1

Low Temperature

1.0

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com