Maintenance & Troubleshooting 3-5

MN605

Carbon Brushes For Special Operating Conditions

Sometimes, there are problems if motor operation requires a different design or grade of carbon brush

than what was installed when the motor was built. These special operating conditions include long periods

of operation with loads that are significantly greater or less than rated load capacity. Also, operation in in

the presence of certain chemicals, or extreme temperature and humidity can degrade brush performance.

Generally, poor brush life or commutator wear can occur if one or more of the above conditions exist. The

brush used doesn’t match the operating conditions.

Baldor offers optional brush grades for the above conditions and has replacement brushes available to

retrofit motors. Contact your local Baldor District Office or an Authorized Baldor Service Center for

technical assistance.

Do not change brush grades or the number of brushes per pole. Doing so may void the warranty and

make the motor unsafe. Contact your local Baldor district office or an authorized Baldor service center for

technical assistance.

Authorized Service

Baldor catalog 505 (and the Baldor CD

−

ROM) lists service shops authorized to service Baldor

DC motors. Contact your local Baldor District Office for more information.

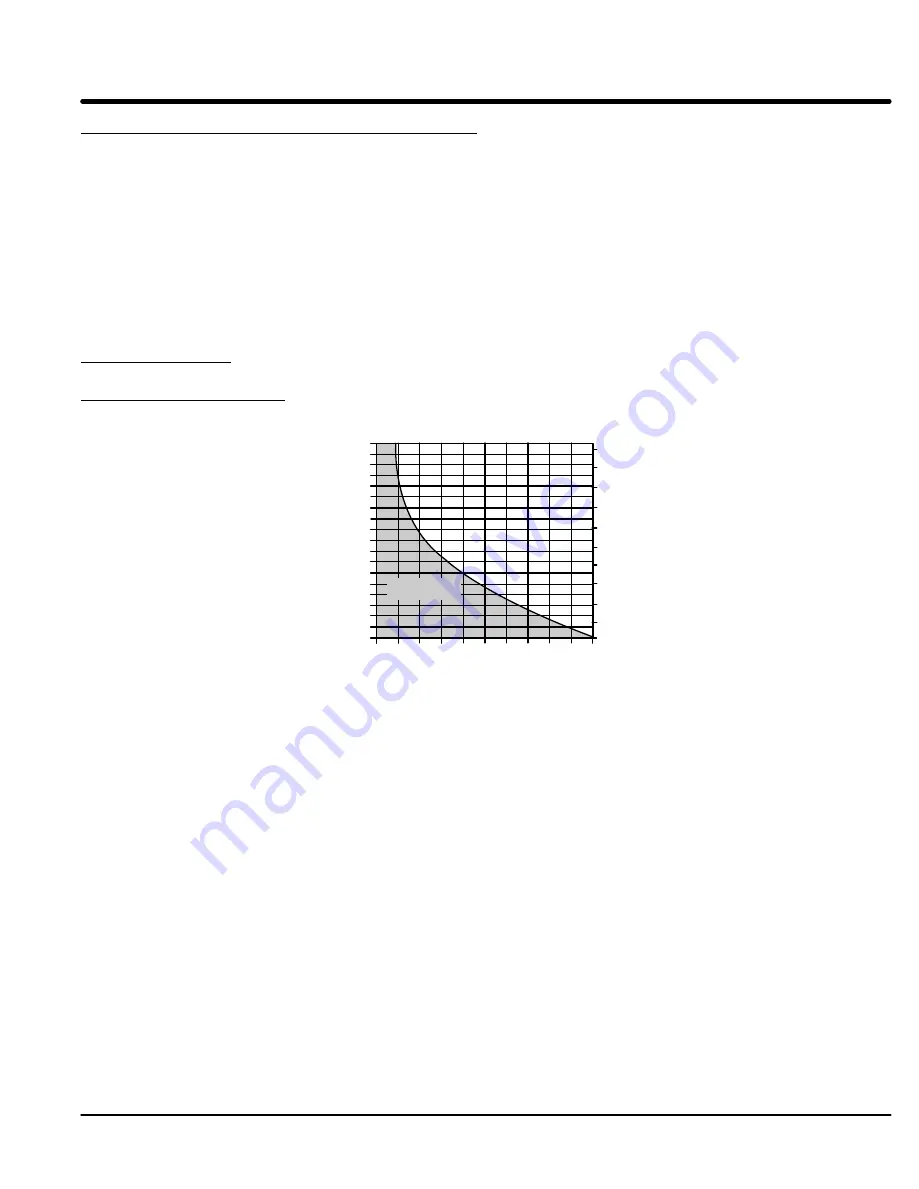

Humidity And Brush Wear

This curve represents 2 grains of water per cubic foot of dry air or 4.6 grams per cubic

meter of dry air.

Zone of Safe Brush Operation

110

100

90

80

70

60

50

40

30

45

40

35

30

25

20

15

10

5

0

10

20

30

40

50

60

70

80

90 100

Percent Relative Humidity

Temperature Degrees F

Temperature Degrees C

Danger Zone

Too Low Humidity

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com