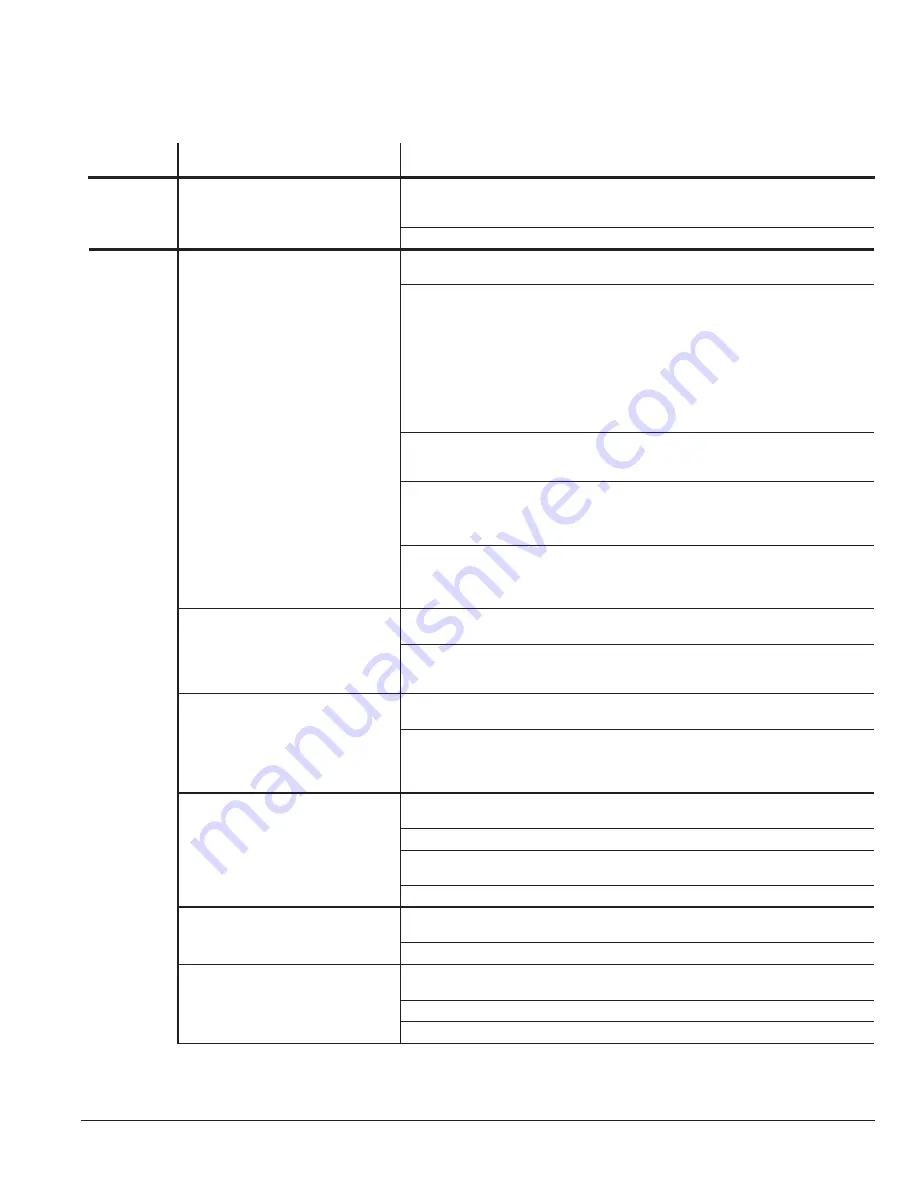

Parameter Descriptions 7-19

MN766

Block Title

Parameter (Number)

Selection (Value)

Parameter Name and Description

DRIVE

PROTECT

(Continued)

Ki RIDE THROUGH

(2215)

Preset Value: 0

Range: 0 to 1000.0000

Integral gain of PI controller for pwer loss ride through.

MISCELLA-

NEOUS

AUTO RESTART

(2301)

Preset Value: 1

Range: 0 - 3

Manual (0)

If set to Manual and a run command (enable signal & FWD or REV

command) is present at power up, the motor will not run. The run command

must be removed then reapplied to start operation. The run command

refers to the enable plus direction (FWD or REV) signals. Restart after

Fault - If a fault occurs during operation, the control must be reset and the

run command must be removed then reapplied to start operation. Note: If

Restarts/Hr (P2302) is zero, the control must be manually reset. If Restarts/

Hr (P2302) is non-zero, the control will automatically attempt to reset the

fault but will not restart until the run command is removed then reapplied to

start operation.

At Powerup (1)

If a run command (enable signal & FWD or REV command) is present at

power up, the control will automatically start. Auto restarts enabled at power

up but disabled after a fault.

After Fault (2)

If a fault occurs during operation, the control will automatically reset (after

the restart delay time) to resume operation if the Restarts/Hr (P2302) is set

to a non zero value. Auto restarts disabled at power up but enabled after a

fault.

Both (3)

Auto restarts active at power up and after faults. 3 Wire modes, AUTO start

after a fault or loss of power will not occur because the momentary contacts

are open and the run command must again be applied. The run command

refers to the enable plus direction (FWD or REV) lines.

RESTARTS/HOUR

(2302)

Preset Value: 3

Range: 0 - 10

The maximum number of automatic restart attempts before requiring a

manual restart. After one hour without reaching the maximum number of

faults or if power is turned off and on again, the fault count is reset to zero.

RESTART DELAY

(2303)

Preset Value: 3

Range: 0 - 3600 seconds

Sets the time delay after a fault occurs before a fault reset and automatic

restart are attemped. If the fault reset is successful, the restart will occur. If

not successful, a new delay occurs. Useful to allow suffi cient time to clear a

fault condition before restart is attempted.

PWM TECHNIQUE

(2304)

Preset Value: 1

Range: 0 - 1

Space Vector (0)

Utilizes Vector Orientation to determine pulse fi ring.

Sine Triangle (1)

Utilizes Sine/Triangle Waveform Intersect technique to determine pulse

widths.

Sets the method used to generate the motor voltage PWM signal.

COST OF ENERGY

(2305)

Preset Value: 0.10

Range: 0.00 - 99999.00$/KWH

Sets the billing cost per KWH charged by the local power utility.

RESET ENERGY

(2306)

Preset Value: 0

Range: 0 - 1

No (0)

No Action.

Yes (1)

Resets the energy counter (in power base of the control).

Table 7-2 Level 2 Parameter Block Defi nitions Continued

Summary of Contents for VS1SD

Page 1: ...05 13 Installation Operating Manual MN766 VS1SD AC Servo Control...

Page 12: ...2 2 General Information MN766...

Page 16: ...3 4 Installing the Drive MN766...

Page 108: ...7 34 Parameter Descriptions MN766...

Page 114: ...8 6 Customizing Your Application MN766...

Page 128: ...9 14 Troubleshooting MN766...

Page 154: ...12 12 Monitor and RTC Description MN766...