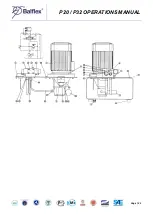

P20 / P32 OPERATIONS MANUAL

Page | 13

EXAMPLE:

Manufacturer has specified a crimping diameter of 20.6 mm for the fitting. Select die set Nº P20/19 (min crimping

diameter 19 mm) according to the die chart. Turn the dial to position 1.60 (upper scale 1, lower 60). This setting will

give the crimping diameter 20.6mm (19+1.6 mm).The machine has been calibrated at the factory with 40 bar pressure.

This means that when you are crimping a fitting requiring 40 bar pressure, the measuring scale of the crimping

diameter dial provides an accuracy of +1- 0.1 mm (possible elastic recovery of the fitting not regarded).

When fittings requiring higher pressure are crimped, the crimping diameter may become larger than the value on

the scale due to machine deflections. Then the crimping diameter has to be corrected by changing the scale value.

CRIMPING MS -CONTROL

WHEN CRIMPING A FITTING, HOLD THE HOSE FAR ENOUGH TO AVOID CRIMPING YOUR HAND!