38

39

BICYCLE

ASSEMBLY

BICYCLE

ASSEMBLY

DERAILLEUR

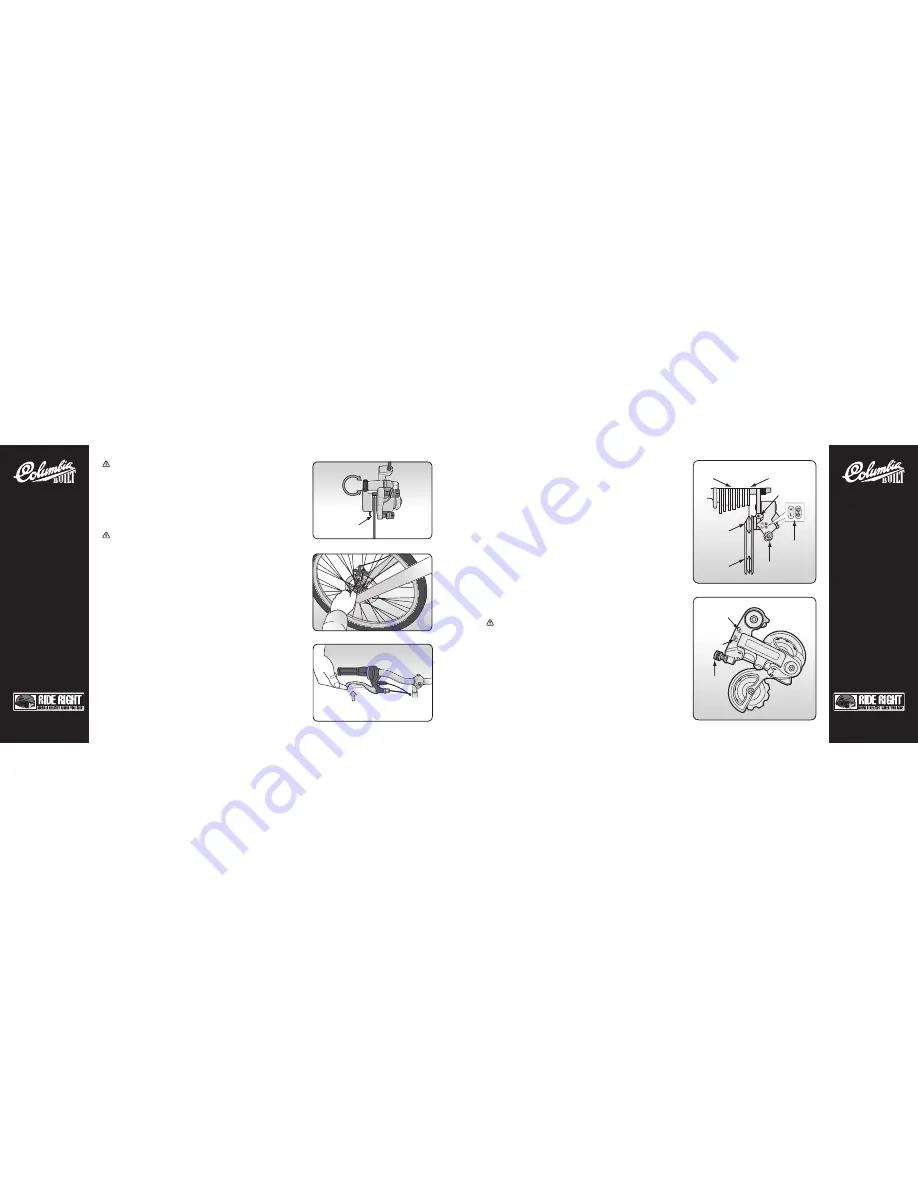

Although the front and rear derailleurs are initially adjusted at the factory,

you will need to inspect and readjust both before riding the bicycle.

REAR DERAILLEUR

Begin by shifting the rear shifter to largest number indicated and place

the chain on the smallest sprocket. Adjust the High limit screw so the

guide pulley and the smallest sprocket are lined up vertically. Reconnect

the cable, pull out any slack, and retighten the anchor bolt securely. Shift

through the gears, making sure each gear achieved is done quietly and

without hesitation. If necessary, use the barrel adjuster to ine tune each

gear by turning it the direction you want the chain to go. For example,

turning clockwise will loosen the cable tension and move the chain away

from the wheel, while turning counter-clockwise will tighten cable tension

and direct the chain towards the wheel. Shift the rear shifter to the gear

one and place the chain on the largest cog. Adjust the Low limit screw

in quarter turn increments until the guide pulley and the largest cog are

aligned vertically. Again, shift through each gear several times, checking

that each gear is achieved smoothly. It may take several attempts before

the rear derailleur and cable is adjusted properly.

(Fig. A, Fig. B)

Ensure all bolts are secured tightly and the chain does not fall off

in either direction.

Freewheel

Outer side of top gear

Pulley

adjustment

screw

Adjustment

screws

SIS cable

adjuster

Tension

Pulley

Guide

Pulley

High gear

adjustment

screw

Low gear

adjustment

screw

Barrel

adjuster

FIG. A

FIG. B

DISC GETS HOT!

Severe injury could result from contact with the hot

disc! Mind your legs, as well as your hands.

These brakes require breaking in! Ride and use the brakes gently for 13

miles before using the brakes in downhill conditions, for sudden stops,

or any other serious braking. Please be aware that your brake system will

change in performance throughout the wear-in process. The disc brake

should be cleaned before the irst ride using rubbing alcohol. NEVER use

oil or similar products to clean your disc brake system.

WARNING:

Disc brakes are sharp, keep ingers away from brake

caliper and rotor. If ingers contact brake while wheel is turning injury

can occur.

After adjusting brake, squeeze the brake lever as hard as you can several

times and re-inspect the brake pads, centering, and brake lever travel.

If the brake pads are no longer square to the rim, repeat brake pad

adjustments. Be sure that brake pads return to a centered position by

spinning the wheel and listening for the brake pad rubbing the rotor on

either side. Readjust as needed. Check that the brake cable tension allows

the brake lever about 1/3 of the travel before the brake pads contact the

rotor. If the cable has stretched or slipped, readjust brake cable tension

by loosening cable anchor bolt and pulling more cable through the anchor

or use brake adjustment barrels for ine tuning brake cable tension.

Adjust brake

caliper so disc

is centered

between

brake pads

FIG. O

FIG. P

FIG. Q