www.balluff.com

2

english

Installation instructions

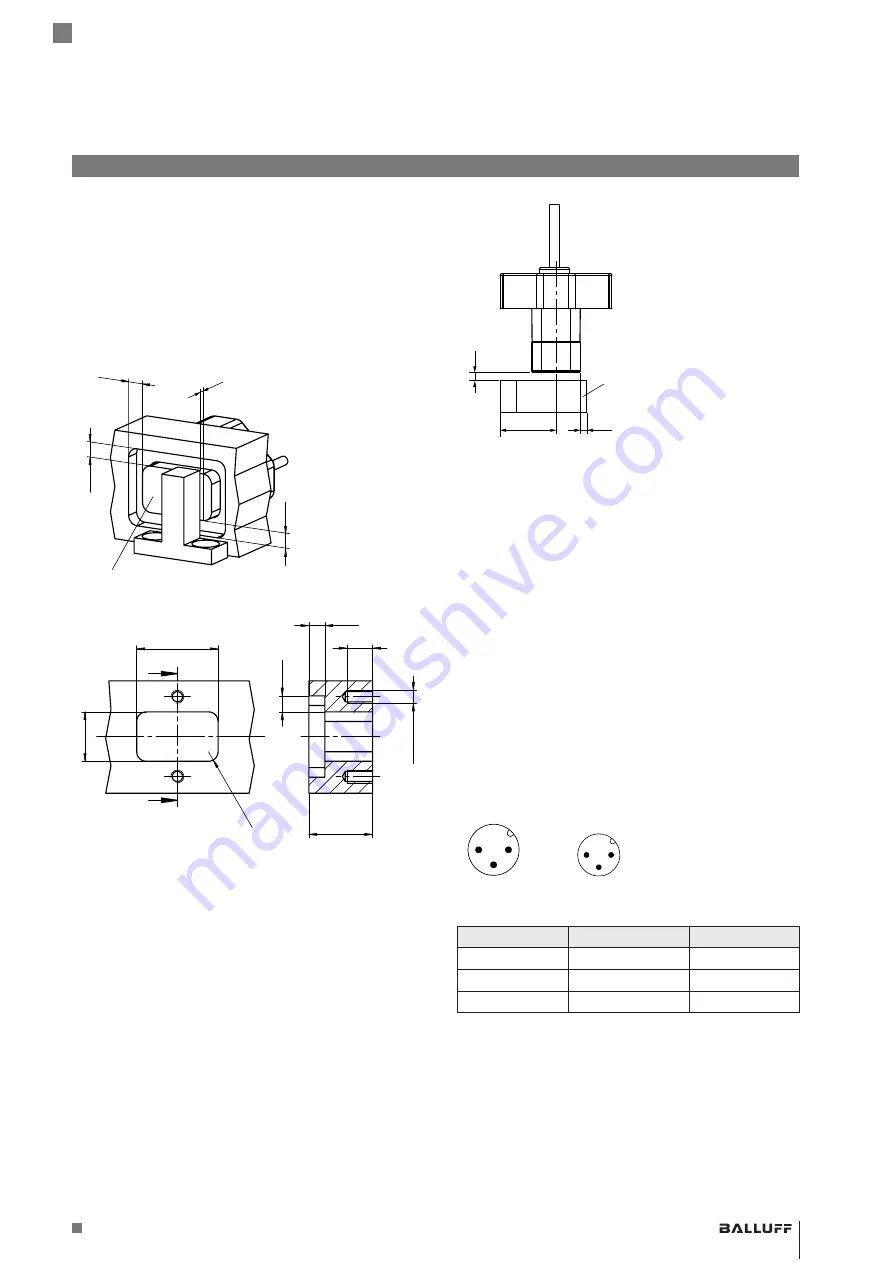

In order to prevent interference with the measurement

signal, a metal-free area of approximately 5 mm should be

maintained around the entire active area of the BIP (see

figure). If the BIP detects not only the target, but also

another metal piece, invalid measurement signals will

result.

To obtain a measurement signal with high resolution,

suitable cable routing in the machine and filter measures

for system power supply must be ensured.

≥5

≥5

D

≥5

Active surface

25.5

15.5

R3

M4 (2×)

8

≥5

≥5

20

The target can be moved in the range D = 0.5…1.25 mm

in front of the active surface in the direction of

measurement (see figure). The resulting linearity error of the

output signal is minimal in the distance range

D = 1.0 ±0.25 mm.

17.5

(2)

D

Target BAM TG-XE-020

Installation

►

Fasten BIP with 2 mounting screws DIN EN ISO 4762

M4 x 14 (max. tightening torque: 0.5 Nm).

Shielding

To ensure electromagnetic compatibility (EMC), the cable

shielding must be grounded on the controller side

(connected with the protective earth conductor).

Cable routing

Do not route the cable between the BIP, controller, and

power supply near high voltage cables (inductive stray

noise is possible).

Inductive stray noise from AC harmonics (e.g. from phase

angle controls) are especially critical and the cable shield

offers very little protection against this.

Electrical connection

1

3

4

S4 connector

1

3

4

S49 connector

Pin (S4/S49)

Wire color

Signal

1

Brown

+

3

Blue

–

4

Black

Output

Installation and connection

BIP A/CD2-T017-01-EB/EP _ _ (-S4/S49)

Inductive Position System