2

Assembling instruction

Connector BKS-S147M-00

No. 827 520 DE

•

Edition 0211; Specifications subject to change without notice.

Usage

The 7-pin connector of the series

BKS-S147M-00 is suitable for cables

with a diameter of 6 to 8 mm.

Technical Data

S147 coupler socket

System

Binder series 423

Nominal voltage

as per VDE 0110/72 Gr. A 60 V

Temperature range

–40...+85 °C

Connection type

soldered

Max. cross-section

0,75 mm

2

Housing material

CuZn, nickel

Socket body

PBTP gv.

Contacts

CuSn + 0,8 µm Au

Protection class

IP 67 as per

IEC 60529 (in screwed state)

Cable inlet

6...8 mm

Cable clamp PG 9

Assembling

Take the 10 parts of the connector

out of the packing.

1

PG Screw

2

Cable clamp

3

Rubber bush

4

Rear housing

5

Braid clamp (coned inside)

6

Braid clamp (coned outside)

7

Slotted spacing tube

8

Socket body

9

Front housing

with tube inside

10 Flat (rubber) gasket

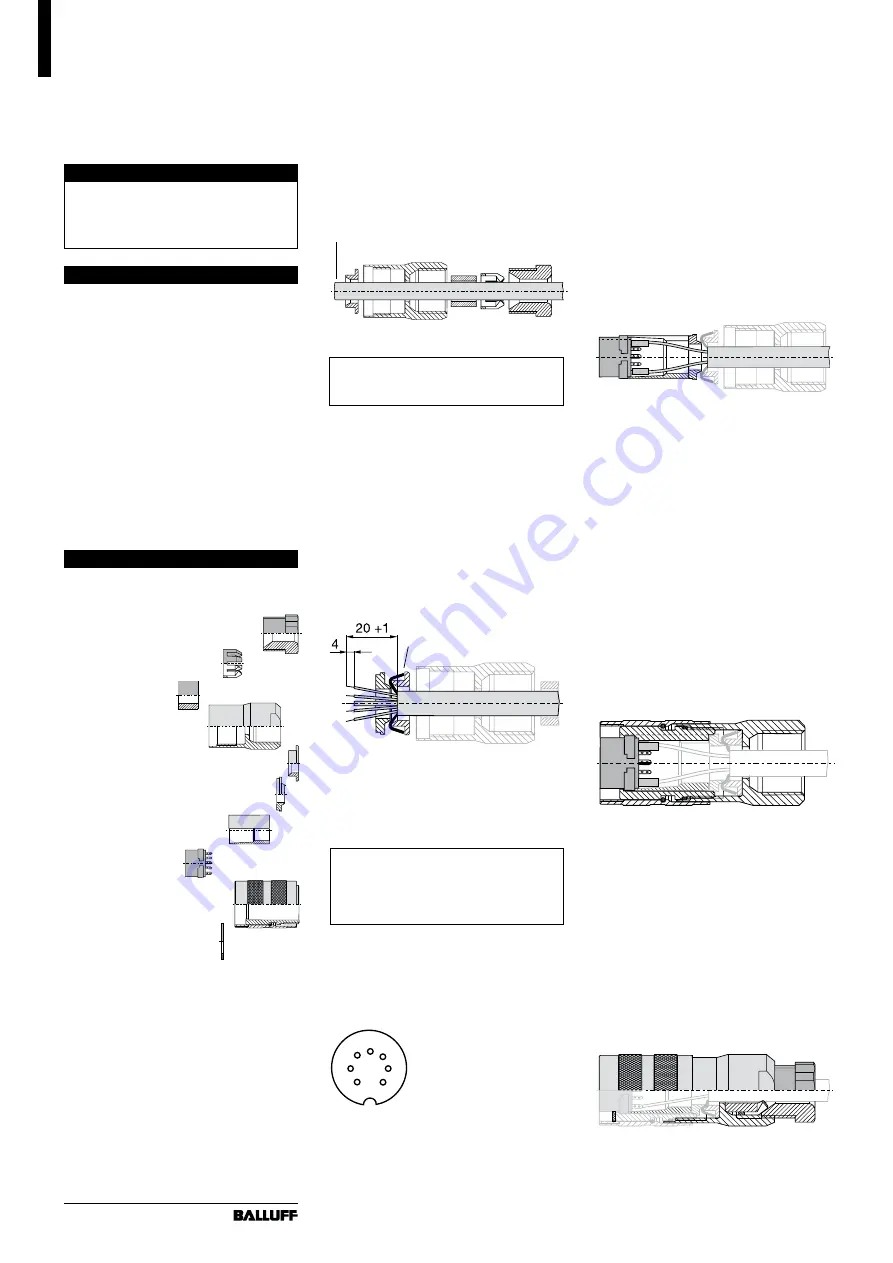

Step 1

(see fig. 1)

Thread the parts 1 to 5 on the cable

in the order shown.

Cable end

(5)

(4)

(3)

(2)

(1)

Fig. 1: Parts threaded on the cable

The PG screw must be screwed

only later - in step 5!

Step 2

(see fig. 2)

Bare and strip the cable braiding for

a length of 20 mm.

Fan out the braid and lay it on the

braid clamp (5), and cut out the over

hanging braid.

Strip the leads for about 4 mm, twist

and coat with a touch of solder.

Thread the braid clamp (6) and

clamp the braid against clamp (5).

(6) (5)

(4)

(3)

Fig. 2: Braid clamped and

the leads stripped

Step 3

(see fig. 3 and 4)

Recommendation: Slip an 8 mm

length of insulating sheath over

each lead. (Not included in deliv-

ery).

Connect the leads to the socket

pins and solder (for pin assignment

see the corresponding BTL operat-

ing manual). Push the insulating

sheaths over the soldered pins.

4

1

5

2

6

7

3

Fig. 3: Socket body (8)

Carefully spread the slotted spacing

tube (7) and usher it over the leads.

Place it on the socket body (8) and

line up the slot with the grove on

the socket body with the noses

wedged so that the socket body

and spacing tube do not turn against

each other.

(8)

(7)

(6) (5)

(4)

Fig. 4: Leads soldered and

spacing tube mounted

Step 4

(see fig. 5)

Slip the front housing (9) from the

front with the inside thread towards

the cable end and make sure that

the wedge on the inside fits in the

grove on the socket body (8) and

the slot on the spacing tube (7).

Screw the front housing (9) on to the

rear housing (4).

While screwing

make sure that the socket body

and the cable are not twisted

(e.g.

by connecting the corresponding

plug of the BTL), in order to avoid

stress on the leads!

(9)

(4)

Fig 5:

Front housing mounted

Step 5

(see fig. 6)

Push the cable clamp (2) over the

rubber bush (3) and both of them

into rear housing (4). Screw in the

PG screw (1) firmly into the rear

housing (torque as per

DIN VDE 0619).

Set the flat gasket (10) from the

front (line up nose and grove) and

carefully press it in all around.

(10)

(3) + (2) (1)

Fig 6:

PG screw screwed,

connector assembled completely

View of pins:

soldering side

Braid laid on,

over hanging braid cut out

Balluff GmbH

Schurwaldstrasse 9

73765 Neuhausen a.d.F.

Germany

Phone +49 (0) 71 58/1 73-0

Fax +49 (0) 71 58/50 10

E-Mail: balluff@balluff.de

http://www.balluff.de