www.balluff.com

2

english

BMF 203K-H- _ _ -C-A _ -… / BMF 235K-H- _ _ -C-A _ -…

Magnetic Field Sensors

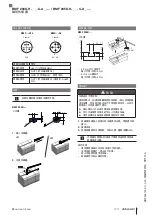

Electrical connection (continued)

BMF…-S75

BMF…-S4

2

1

4

3

Class A

M 8

2

1

4

3

Class A

M 12-4

Pin / wire color

Signal

Pin 1/brown

+24V (operating voltage UB+)

Pin 2/white

OUT2 (Switching output S2)

Pin 3/blue

GND (operating voltage UB–,

reference potential)

Pin 4/black

OUT1 (Switching output S1) or

C/Q for IO-Link

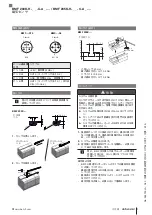

Installation

For determining the installation position see

user’s guide.

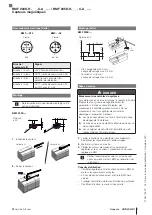

BMF 203K-…

C-slot

3

2.2

R1.8

4

3.8...4.2

3.0...3.2

1.

Insert the sensor.

Variant A

Variant B

2.

Tighten the sensor.

0.9

max. 0.07 Nm

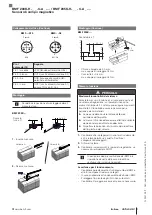

Installation (continued)

BMF 235K-…

T-slot

0.9

max. 0.07 Nm

2.0

max. 0.4 Nm

5.0…5.4

> 3.5…> 6.0

< 4.0

– Allen wrench, 2.0 mm:

max. torque 0.4 Nm

– Screwdriver, 4×0.8 mm:

max. torque 0.4 Nm

Startup

DANGER

Uncontrolled system movement

When starting up, if the sensor is part of a closed loop

system whose parameters have not yet been set, the

system may perform uncontrolled movements. This

could result in personal injury and equipment damage.

►

Persons must keep away from the system’s

hazardous zones.

►

Startup must be performed only by trained technical

personnel.

►

Observe the safety instructions of the equipment or

system manufacturer.

1.

Check connections for tightness and correct polarity.

Replace damaged connections.

2.

Turn on the system.

3.

Check measured values and adjustable parameters

and readjust the BMF if necessary.

Check for the correct values, especially after

replacing the BMF or after repair by the

manufacturer.

Operating notes

– Regularly check function of the BMF and all associated

components.

– Take the BMF out of service whenever there is a mal-

function.

– Secure the system against unauthorized use.

– Check fasteners and re-tighten if needed.

No. 944153 EN · A20; subject to modification. Replaces K19.