1

english

BTL PA0400- _ _ _ _ -B15A_010-000S92

Magnetostrictive Linear Position Sensor – Profile Style

The CE Mark verifies

that our products meet the requirements

of the current EU Directive.

About this guide

This guide provides all the information required for the safe

use of the BTL magnetostrictive linear position sensor with

analog current and voltage interface.

It applies to the following models:

–

BTL PA0400- _ _ _ _ -B15A_010-000S92

Intended use

The BTL magnetostrictive linear position sensor, together

with a machine controller (e.g. PLC), comprises a position

measuring system. It is intended to be installed into a

machine or system and used in the industrial sector.

Proper function according to the information in the

technical data is only guaranteed if the product is used

solely as described in the user’s guide and the associated

documents as well as in compliance with the technical

specifications and requirements and only with a suitable

original Balluff accessory.

Otherwise, it is deemed non-intended use. Non-intended

use is not permitted and will result in the loss of warranty

and liability claims against the manufacturer.

Safety notes

Activities such as

installation

,

connection

and

commissioning

may only be carried out by qualified

personnel.

Qualified personnel

are persons whose technical

training, knowledge and experience as well as knowledge

of the relevant regulations allow them to assess the work

assigned to them, recognize possible hazards and take

appropriate safety measures.

The

operator

is responsible for ensuring that local safety

regulations are observed.

In particular, the operator must take steps to ensure that a

defect in the product will not result in hazards to persons

or equipment.

The product must not be opened, modified or changed. In

case of defects and unrepairable malfunctions of the

product, it must be taken out of operation and secured

against unauthorized use.

Other applicable documents

A comprehensive user’s guide and additional information

about this product can be found at

www.balluff.com

on

the product page.

Reasonably foreseeable misuse

The product is not intended for the following applications

and areas and may not be used there:

– In safety-oriented applications in which personal safety

depends on the device function

– In explosive atmospheres

– In food applications

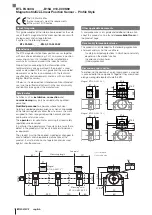

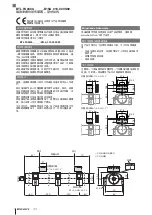

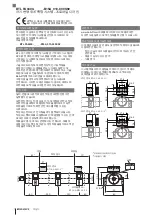

Dimensions and function

To determine the position of a plant component, a magnet

is connected to the component. Together they are moved

along a waveguide located inside the BTL.

C

55-4

10.8

21 A

28

16

37.6

Ø 4.2

B

5

28.2

Magnet BTL6-A-3800-2

1)

C

55-4

5

21 A

B1

8

28

16

37.6

Ø 4.2

Magnet BTL6-A-3801-2

1)

~60

~60

60

50

Ø 5.5

Ø 30

18

37

55-4

M12x1

70

2)

67

2)

~250

~250

21

Slot

1) Not included

2) unusable area

Mounting cuff

1)

BTL6-A-MF03-K-50

Magnet

BTL6-A-3801-2

1)

Measuring length

Null point

End point