www.balluff.com

2

BTL5-A/C/E1_ -M _ _ _ _ -SF-F _ _

Micropulse Transducer - Rod Style

No. 863800 EN · G13; Subject to modification. Replaces B13.

english

Shielding and cable routing

Defined ground!

The transducer and the control cabinet must be

at the same ground potential.

Shielding

To ensure electromagnetic compatibility (EMC), observe

the following:

– Connect the transducer and controller using a shielded

cable.

Shielding: Braided copper shield with minimum 85%

coverage.

– On the transducer side, the cable shielding is

connected to the housing. Ground the cable shielding

on the controller side (connect with the protective earth

conductor).

Magnetic fields

The position measuring system is a magnetostrictive

system. It is important to maintain adequate distance

between the transducer/holding cylinder and strong,

external magnetic fields.

Cable routing

Do not route the cable between the transducer, controller,

and power supply near high voltage cables (inductive stray

noise is possible).

Cable length

The maximum cable length is 20 m (Ø 6-8 mm).

Bending radius for fixed cable

The bending radius for a fixed cable must be at least five

times the cable diameter.

Starting up the system

1.

Check connections for tightness and correct polarity.

Replace damaged connections.

2.

Turn on the system.

3.

Check measured values (especially after replacing the

transducer).

DANGER

Uncontrolled system movement

When starting up, if the position measuring system is part

of a closed loop system whose parameters have not yet

been set, the system may perform uncontrolled

movements. This could result in personal injury and

equipment damage.

►

Persons must keep away from the system’s

hazardous zones.

►

Startup must be performed only by trained technical

personnel.

►

Observe the safety instructions of the equipment or

system manufacturer.

Operating notes

– Check the function of the position measuring system

and all associated components on a regular basis.

– Take the position measuring system out of operation

whenever there is a malfunction.

– Secure the system against unauthorized use.

– Observe the directives of the FDA and 3-A SSI for

monitoring hygiene and cleaning of the device, as well

as the instructions for operation and maintenance of

the entire system. This especially applies to the

selection of sealants, which must be FDA and 3A

SSI-conformant, as well as temperature-resistant and

chemically resistant for the cleaning methods applied.

– Regularly check the entire device for damage and signs

of wear.

– Regularly check the rod for cracks (e.g. with a color

penetration test) and exchange it if damaged. This

especially applies if the sensor is subjected to heavy

product movements or other mechanical influences.

– It is possible to clean the device on-site (CiP

1)

).

– As part of a cleaning validation, the cotter pin and the

float must be removed and checked. Check the holes

in the float and all surfaces that come into contact with

the product for cleanliness and clean them, if

necessary. This also applies to the area near the

welded port. If cleanliness is not achieved, the cleaning

method must be adjusted.

1)

Clean in Place

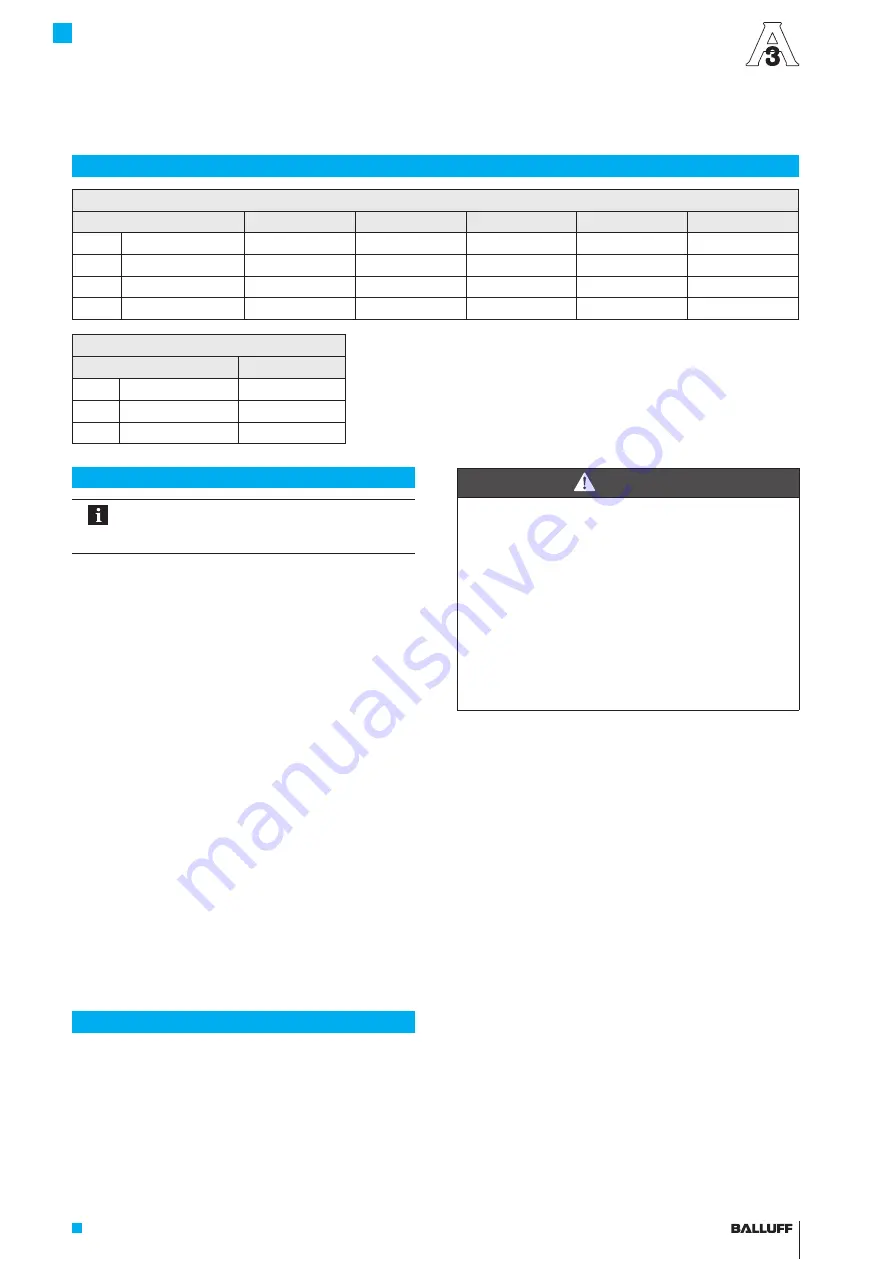

Electrical connection

Output signals

1)

Cable

BTL5-A11

-C10

-C17

-E10

-E17

YE

Yellow

Not used

3)

0 to 20 mA

20 to 0 mA

4 to 20 mA

20 to 4 mA

GY

Gray

0 V

0 V

0 V

0 V

0 V

PK

Pink

10 to 0 V

2)

Not used

3)

Not used

3)

Not used

3)

Not used

3)

GN

Green

0 to 10 V

2)

Not used

3)

Not used

3)

Not used

3)

Not used

3)

Supply voltage (external)

1)

The connection assignments depend on the respective version.

2)

Because of the separate output drivers there are small voltage

differences between PK and GN (offset < 10 mV).

3)

Unassigned leads can be assigned to GND on the process controller

side, but they must never be connected to the shield.

Cable

BTL5-A/C/E1

BU

Blue

GND

BN

Brown

+24 V

WH

White

Not used

3)

74-06