1-800-543-8390

•

WWW.BALLUFF.COM

BTL5-P/I/K/L/M_-M/U_ _ _ _-P-S32/KA_ _

Micropulse Linear Transducer

Digital Output / Profile Housing

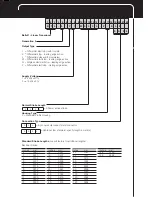

4 Wiring

straignt

BKS-S 32M-00

right-angle

BKS-S 33M-00

Cable entry

(PG 9 fitting)

Note the following

when making

electrical connec-

tions:

System and control cabinet

must be at the same

ground potential.

To ensure the electromagnetic

compatibility (EMC) which

Balluff warrants with the CE

Mark, the following instruc-

tions must be strictly

followed.

BTL transducer and the

processor/control must be

connected using

shielded cable.

Shielding: Copper filament

braided, 80% coverage.

The shield must be tied to the

connector housing in the

BKS connector (Fig. 4-1); see

instructions accompanying

the connector.

In the cable version the cable

shield is connected to the

housing in the PG fitting.

The cable shield must be

grounded on the control side,

i.e., connected to the

protection ground.

Pin assignments can be

found in Table 4-1. Connec-

tions on the controller side

may vary according to the

controller and configuration

used.

When routing the cable between

the transducer, controller and

power supply, avoid proximity to

high voltage lines to prevent noise

coupling.

Especially critical is inductive

noise caused by AC harmonics

(e.g. from phase-control devices),

against which the cable shield

provides only limited protection.

Cable length max. 500 m ;

Ø 6 to 8 mm.

High noise immunity on the line

between the transducer and

processor is provided by the

differential line drivers used for

the RS 485/422 interface. The

differential signal is carried to the

processor, which makes it

available as analog or digital

information for

further processing.

Fig. 4-1: Connector (optional)

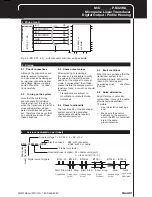

1

YE

3

PK

Inter Input

Interrogate - Input

2

GY

5

GN

Pulse + Output

Pulse - Output

7

BN

6

BU

+24 V

GND

Digital, RS485 differential

24 V (P, M, I, K, L, R)

8

WH

GND

0117a025

1

2

3

4

5

6

7

8

View of mating

connector, wiring side

1

YE

Inter Input

2

GY

Pulse + Output

7

BN

6

BU

+24 V

GND

Digital, Single-ended

24 V (N)

8

WH

GND

0117a026

1

YE

3

PK

Inter Input

Interrogate - Input

2

GY

5

GN

Pulse + Output

Pulse - Output

7

BN

6

BU

+15 V

GND

Digital, RS485 differential

±15 V (P, M, I, K, L, R)

8

WH

-15 V

0117a027

1

YE

Inter Input

2

GY

Pulse + Output

7

BN

6

BU

+15 V

GND

Digital, Single-ended

±15 V (N)

8

WH

- 15 V

0117a028

Fig. 4-2: Pin assignments BKS,

connector type BTL

BKS connector,

view towards

solder side of

female BKS-S

32M-00 or BKS-S

33M-00

Summary of Contents for BTL5-P

Page 2: ......