BTL5-T1_ _-M_ _ _ _-A/B/Y/Z-SA366-S103

Micropulse Transducer – Rod Style

1

english

EU Directive 2004/108/EG (EMC Directive) and EMC law

Noise immunity: EN 61000-6-2

Emission: EN 61000-6-4

File No.

E227256

Intended use

The BTL5 Micropulse transducer is

intended to be installed in a machine

or system. Together with a controller

(PLC) or a master it comprises a

position measuring system and may

only be used for this purpose.

Installation

Ensure that no strong

electrical or magnetic

fields are present in the

immediate vicinity of the transducer.

The contact surface of the transducer

must be completely contacted by the

mounting surface. The O-ring supplied

must make a perfect pressure seal.

To achieve secure mounting, use the

proper nut for the mounting thread.

When tightening the nut, do not

exceed a tightening torque of 100 Nm.

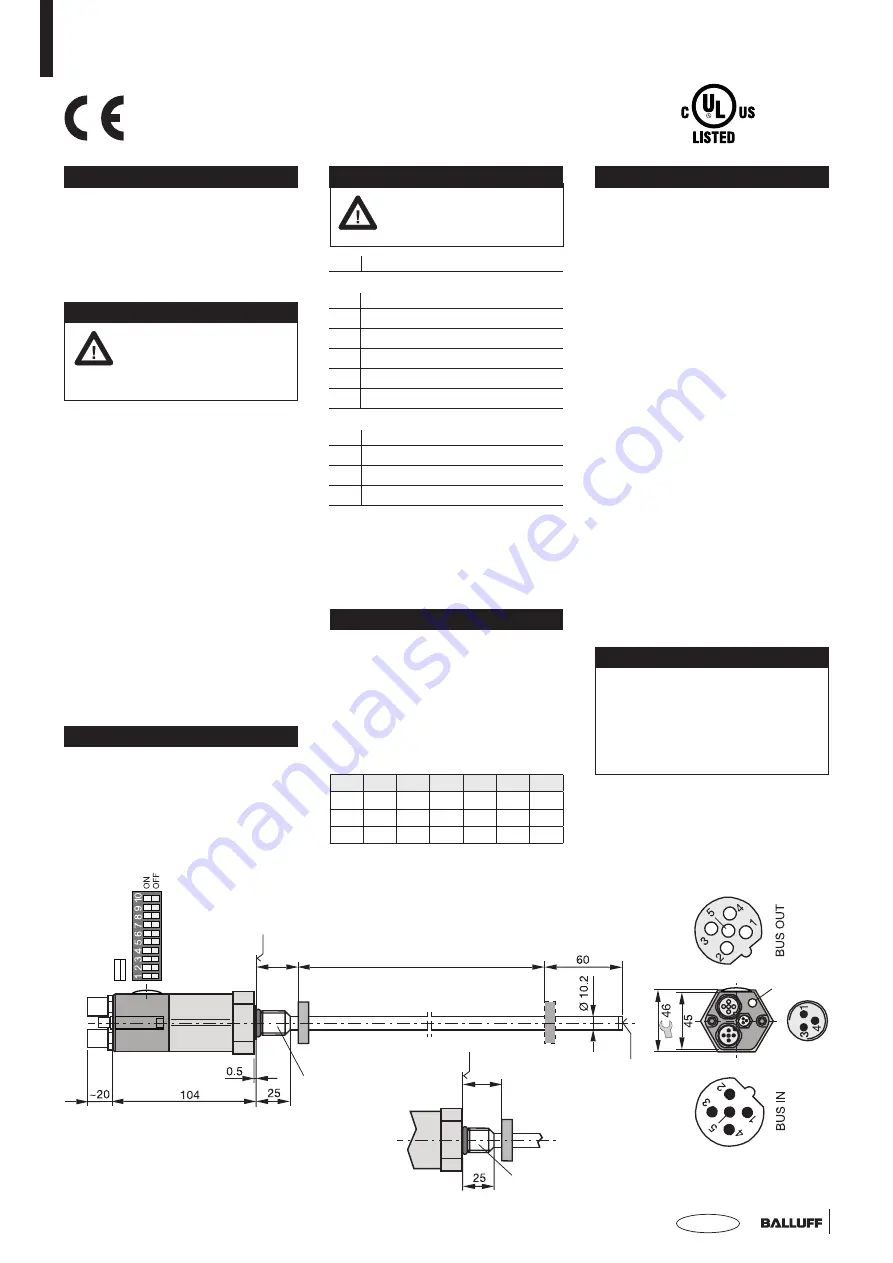

For horizontal mounting of transducer

with stroke lengths greater than

500 mm, the pressure tube should

be supported or attached at its end.

When installing in a hydraulic cylinder,

do not allow the magnet ring to rub

against the pressure tube. The bore

diameter in the piston and cylinder rod

should be at least 13 mm. Permissible

values for distance and center offset

are indicated in the drawing.

SA366:

LED visible on front face via light

guide.

Startup

Observe all relevant safety regulations!

Check connections:

Components

can be damaged by improper

connections and overvoltage. Verify all

connections before applying power!

Turning on the system:

Note that

the system may execute uncontrolled

movements when the transducer is

part of a closed-loop system whose

parameters have not yet been set.

Therefore make sure that no hazards

could result from these situations.

Check functionality:

The functionality

of the transducer system and all its

associated components should be

regularly checked and recorded. In

particular, steps must be taken to

ensure that should the transducer

system become defective no hazards

to persons or property can result.

Fault conditions:

When there is

evidence that the transducer system

is not operating properly, it should

be taken out of service and guarded

against unauthorized use.

Wiring

System and control cabinet

must be at the same ground

potential.

No. 895 136 E • Edition 1303; Subject to modification.

➀

Not included.

Connector

➀

for Bus In / Bus Out:

straight: BKS-S103-00 / S105-00

right-angle: BKS-S104-00 / S106-00

Cable with connector

➀

for Power:

BKS-S 48-15-CP-_ _

Nominal length =

measuring range

Damping zone

Mounting surface

Magnet

➀

B: 30 -1 mm

Z: 2" -0.04 "

Thr

ead

M4 × 4/6 deep

Electrical connection

Pin BTL5-T1...S103

Data signals PROFIBUS-DP

Bus In / Bus Out

1

VP +5 V (output)

2

RxD / TxD-N (A)

3

Data GND

4

RxD / TxD-P (B)

5

Shield

Supply voltage (external)

Power

1

+24 V

3

0 V (GND)

4

Shield

Configuration

Station address:

Values from 0...127 allowed;

Value 0...125 = station address

Value 126 = address 126 or the

address set by

Set_Slave_Address

Value 127 = reset BTL to its default

condition

(female)

Power

(male)

View towards

connectors

(male)

Bus termination S1.9 and S1.10 = ON

User's Manual

A detailed user's manual and

configuration guide can be

obtained on the Internet at

www.balluff.com\downloads-btl5

or via e-mail to

PROFIBUS@balluff.de

Mounting

surface

Thread:

B: M18x1.5

Z: 3/4"-16UNF

A: 30 -1 mm

Y: 2" -0.04 "

Thread:

A: M18x1.5

Y: 3/4"-16UNF

➁

Unusable area.

➁

➁

S1

LED

S1.1 S1.2 S1.3 S1.4 S1.5 S1.6 S1.7

2

0

2

1

2

2

2

3

2

4

2

5

2

6

LSB

MSB

1

2

4

8

16

32

64

gr

een

re

d