BTL6-A/E500/B50 _ -M _ _ _ _ -E2/E28-KA _ _ /LA _ _ -ZA _ _

Magnetostrictive Linear Position Sensor – Rod Style

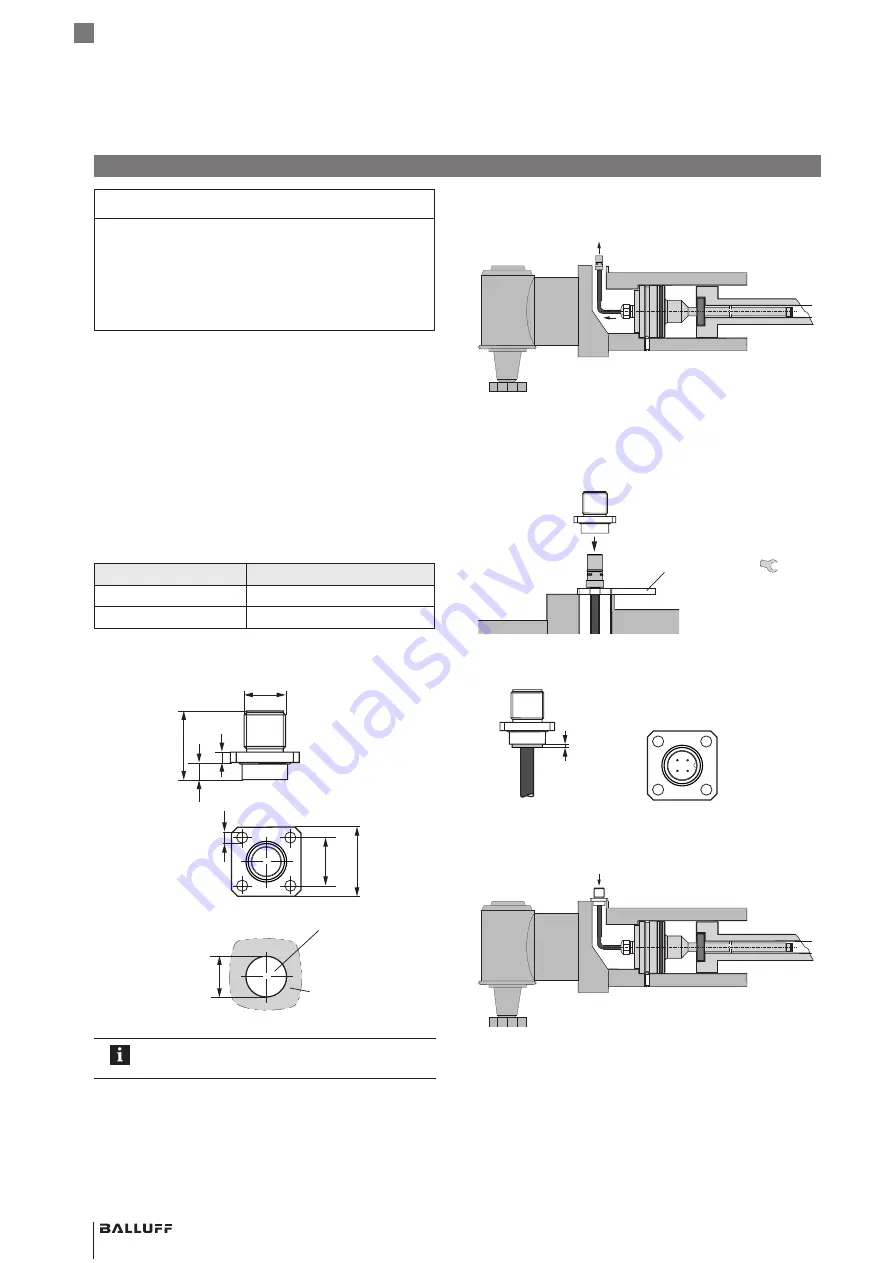

Installation in hydraulic cylinders

1.

Lead the M12 contact insert through the mounting hole

and out of the cylinder.

2.

Support the contact insert on the 8-mm open-end

wrench. Attach the square flange onto the M12 contact

insert and press it with force until the insert audibly

engages.

When mounted, the contact insert protrudes from the

bottom of the square flange by approx. 2 mm.

2

3.

Fasten the square flange to the hydraulic cylinder using

4 screws. When installed, the connector complies with

protection category IP67.

NOTICE!

Interference in function

Improper installation can compromise the function of the

BTL and result in increased wear.

►

The mounting surface of the BTL must make full

contact with the supporting surface.

►

The bore must be perfectly sealed (O-ring/flat seal).

The BTL can be fastened in a fitting bore (Ø 48 H8), but

must be sealed with the provided O-ring and support ring.

The body of the BTL is fastened using 3 M5 threaded pins

at a 120° angle.

For horizontal assembly with nominal lengths > 500 mm,

support the rod and tighten it at the end if necessary (only

possible with a diameter of 10.2 mm).

If installed in a hydraulic cylinder, the magnet should not

make contact with the rod. Minimum bore diameter in the

support piston:

Rod diameter

Bore diameter

10.2 mm

At least 13 mm

8 mm

At least 11 mm

Square flange

20

5

3

M12x1

Ø 13.3

+0.10 -0.00

14

20

Ø 3.2

The square flange is included in the scope of

delivery.

2

english

Installation

M12 contact insert

Square flange

8-mm open-end wrench

Top view

Mounting hole

Hydraulic cylinder