www.balluff.com

2

No. 926300 EN · C16; Subject to modification.

english

Screw the transducer thread into the mounting hole

(max. torque 100 Nm).

Radial cable outlet

During installation, the direction of the cable

outlet is specified by the thread.

For horizontal assembly with nominal lengths > 500 mm,

support the rod and tighten it at the end if necessary (only

possible with a diameter of 10.2 mm).

If installed in a hydraulic cylinder, the magnet should not

make contact with the rod. Minimum bore diameter in the

support piston:

Rod diameter

Bore diameter

10.2 mm

At least 13 mm

8 mm

At least 11 mm

Startup

DANGER

Uncontrolled system movement

When starting up, if the position measuring system is part

of a closed loop system whose parameters have not yet

been set, the system may perform uncontrolled

movements. This could result in personal injury and

equipment damage.

►

Persons must keep away from the system's

hazardous zones.

►

Startup must be performed only by trained technical

personnel.

►

Observe the safety instructions of the equipment or

system manufacturer.

1.

Check connections for tightness and correct polarity.

Replace damaged connections.

2.

Turn on the system.

3.

Check measured values and adjustable parameters

regularly (especially after replacing the transducer or

after repair by the manufacturer). Recalibrate the

transducer, if necessary.

The calibration procedure is described in the

comprehensive user's guide.

Shielding and cable routing

Defined ground!

The transducer and the control cabinet must be

at the same ground potential.

Shielding

To ensure electromagnetic compatibility (EMC), observe

the following:

– Connect the transducer and controller using a shielded

cable.

Shielding: Copper filament braided, at least 85%

coverage.

– Cable version: On the transducer side, the cable

shielding is connected to the housing.

Ground the cable shielding on the controller side

(connect with the protective earth conductor).

Magnetic fields

The position measuring system is a magnetostrictive

system. It is important to maintain adequate distance

between the transducer cylinder and strong, external

magnetic fields.

Cable routing

Do not route the cable between the transducer, controller,

and power supply near high voltage cables (inductive stray

noise is possible). The cable must be routed tension-free.

Cable length

BTL7-A

Max. 30 m 1)

BTL7-E

Max. 100 m 1)

1) Prerequisite: Construction, shielding and routing preclude the effect of

any external noise fields.

Installation

NOTICE!

Interference in function

Improper installation can compromise the function of the

transducer and result in increased wear.

►

The mounting surface of the transducer must make

full contact with the supporting surface.

►

The bore must be perfectly sealed (O-ring/flat seal).

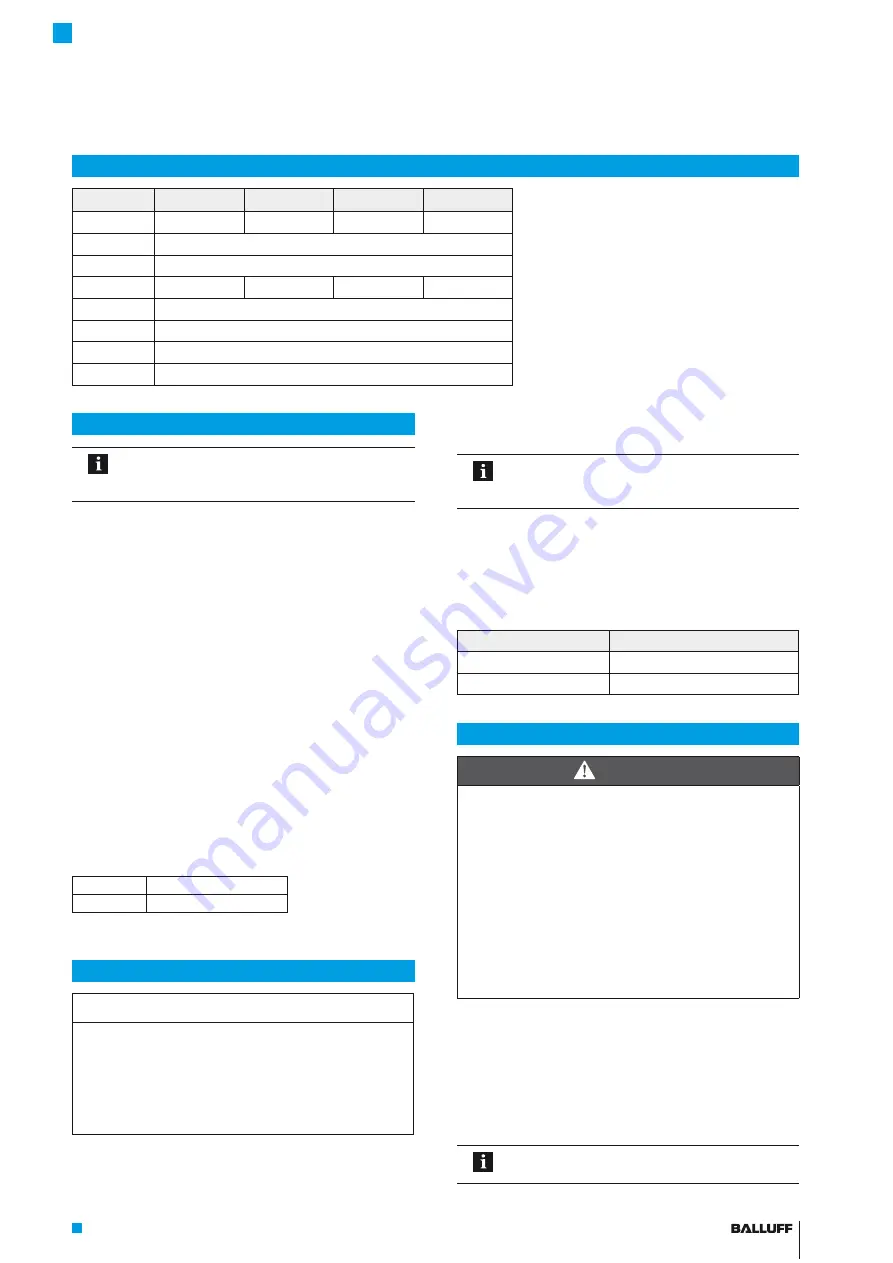

BTL7-A/E1 _ 0-M _ _ _ _ -H/W(8)-SA262-KA _ _ /K _ _ /FA _ _ /F _ _

Micropulse Transducer - Rod Style

Electrical connection

Cable color

-A100

-A170

-E100

-E170

YE yellow

Not used 1)

Not used 1)

4…20 mA

20…4 mA

GY gray

0 V

PK pink

La (programming input)

1) Unassigned leads can be connected to GND on the

controller side but not to the shield.

2) Reference potential for supply voltage and EMC-

GND.

3) Not for BTL7-…-SA262-K_ _ and

BTL7-…-SA262-KA_ _

GN green

0…10 V

10…0 V

Not used 1)

Not used 1)

WH white

Lb (programming input)

BU blue

GND 2)

BN brown

20…28 V

RD red 3)

Not used 1)