8

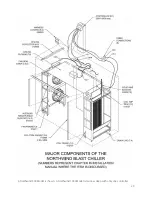

3.3

On each panel, check for proper

alignment and level. Leveling can be

accomplished by placing wooden shims

under the vertical panels (cross-

reference IM-268-11, Section6).

3.4

Remove the shipping strap attached to

the bottom of the door opening. When

attaching the door, hold a level on the

face of the door section, and when

plumb, Speed-Lok to adjacent corner

section.

IT IS VERY IMPORTANT THAT

THE DOOR SECTION IS ALWAYS LEVEL

AND PLUMB.

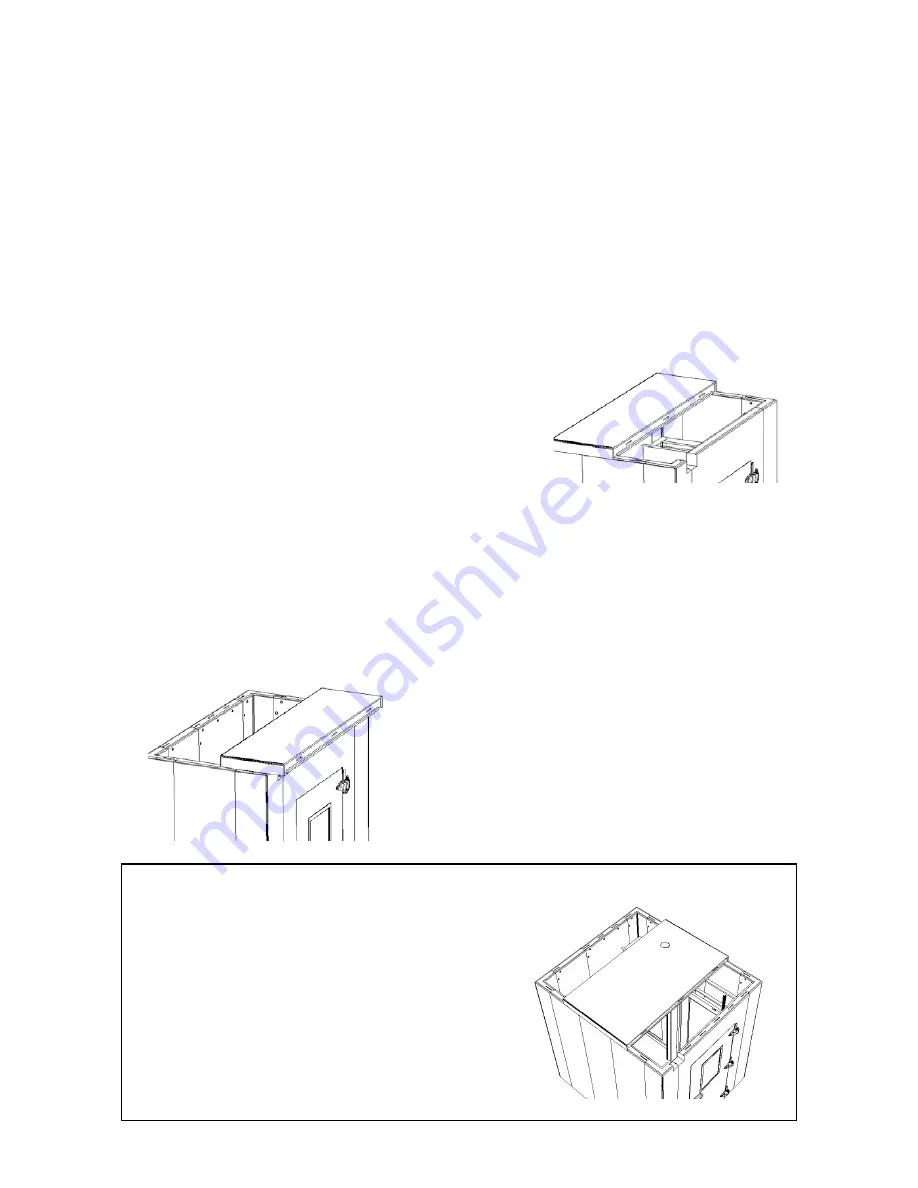

4.

Installation of the Ceiling Panels

4.1.

Bring the rear ceiling panel on top of

the front half of the blast chiller.

4.2.

Caulk on both sides of the tongues of all the

appropriate rear wall panels.

4.3.

Pick up the ceiling panel, bring it back, and

drop it in place. Engage a couple of locks on

the back wall.

Do not fully lock.

4.4.

Caulk the groove or tongue of the rear

ceiling panel and the rest of the wall tongue

area.

4.5.

Bring up the front ceiling panel and lock it to

the back ceiling panel, fully engaging the

Speed-Loks to the lock position on the seam

between the two

ceiling panels

.

4.6.

Make sure the ceiling panels are secured

squarely on the vertical panels.

Do not fully

lock.

Align and adjust accordingly.

4.7.

Fully engage the Speed-Loks to the lock

position on the

vertical panels

to the

ceiling panels.

Installing Ceiling Panels on the Northwind 1000

•

Install the middle ceiling panel first. The large

panel will align more panels quicker.

•

Instead of caulking the tongues, place the

caulk in the corners of the grooves in the

ceiling panel, then lay the ceiling panel on a

piece of cardboard trimmed to size.

•

Lift the ceiling and cardboard onto the

verticals, locate the ceiling panel, tilt it up,

and remove the cardboard.