Maintenance

Procedures

(continued)

12

SPRAY

NOZZLE

SPRAY

NOZZLE

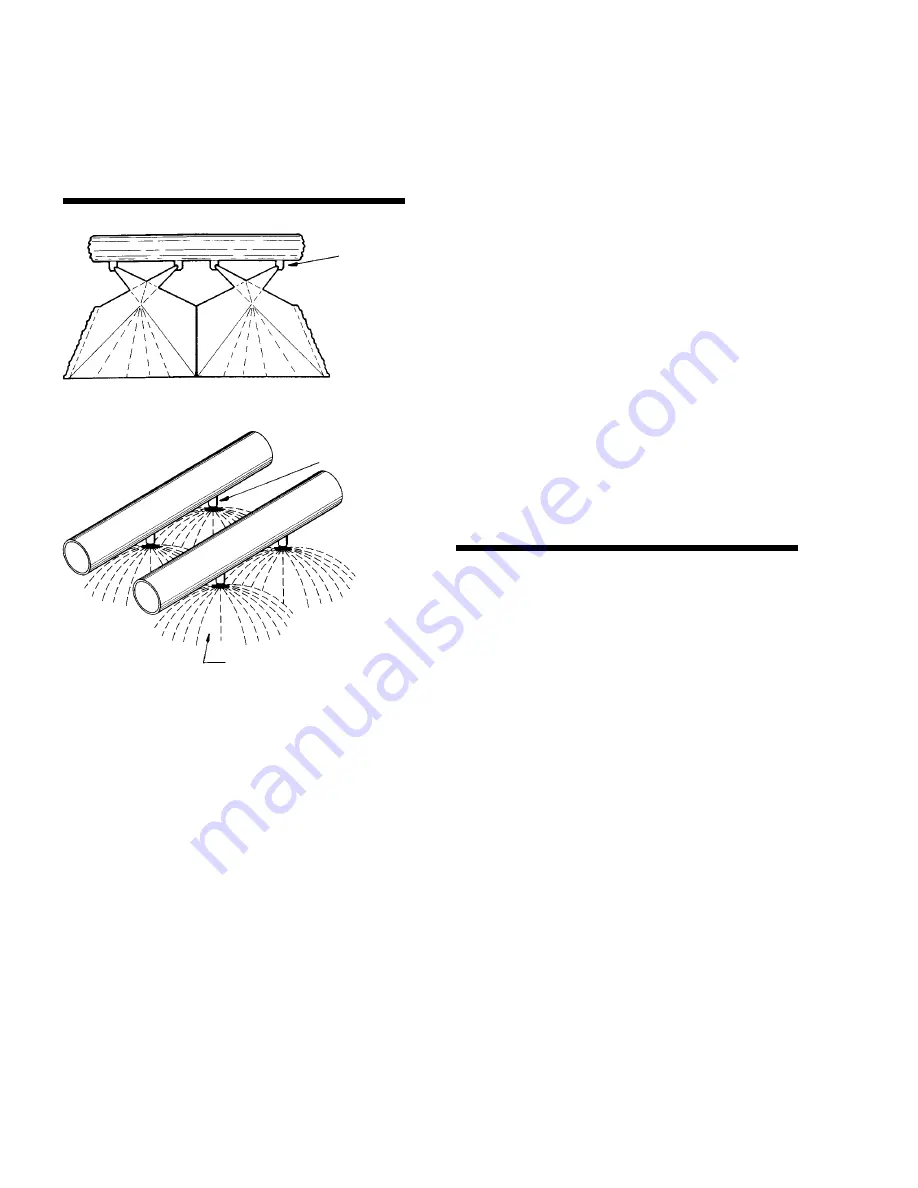

360° UMBRELLA TYPE SPRAY

Figure 7a – Nozzle Spray Distribution (Cooling Towers)

Figure 7b – Nozzle Spray Distribution (Coil Products)

CORROSION PROTECTION

Series V units are constructed entirely of corrosion-resis-

tant materials. The wet deck surface and the eliminators

of the VT1, VTO and VTL are made of polyvinyl chloride

(PVC) which requires no protection against rot, decay,

rust, or biological attack. The standard coil of the VF1,

VFL, VC1, VC2, and VCL is constructed of all prime sur-

face steel, hot-dip galvanized after fabrication. The bal-

ance of the construction in all units is either heavy-gauge

galvanized steel, the optional BALTIBOND® Corrosion

Protection System, or Type 304 stainless steel.

Galvanized Steel Construction

The standard Series V and Low Profile Series V units are

constructed of hot-dip galvanized steel. These units

should be inspected annually.

Cold Weather

Operation

Inspect the inside of the unit for blemishes or corrosion on

the galvanized steel. Affected areas should be thoroughly

wire brushed and recoated with zinc-rich compound (ZRC).

BALTIBOND

®

Corrosion Protection System

The Series V and Low Profile Series V units can be con-

structed of hot-dip galvanized steel, protected with the

BALTIBOND® Corrosion Protection System as an option.

Scratches and scrapes on parts which do not require

extraordinary corrosion protection can be touched up with

a repair kit (B.A.C. Part No. 16-133P). In the unlikely

event that the damage is more extensive than simple

scratches or dents, contact your local B.A.C. Representative.

Series V and Low Profile Series V equipment can be oper-

ated in subfreezing ambient conditions provided proper

measures are taken:

1. Protection against basin water freezing when the unit

is idle.

2. Capacity control to prevent ice formation in heat trans-

fer sections during operation.

3. Protection against coil freezing (VF1 and VFL Closed

Circuit Cooling Towers and cooling circuits in VC1,

VC2, and VCL Evaporative Condensers.

Cold weather applications should be reviewed with the

B.A.C. Representative in your area to ensure that the unit

selection, location, control, and accessories are adequate

for reliable operation. Listed below are general guidelines,

which should be followed to minimize the possibility of

freeze-up.

PROTECTION AGAINST BASIN WATER FREEZING

When the unit is shut-down and exposed to subfreez-

ing ambient temperatures, the basin water may freeze.

A remote sump located in a heated indoor area is a desir-

able method of freeze protection. Alternatively, basin

heaters, electrical immersion heaters, steam coil, or hot

water coil) can be used to maintain the basin water at a

minimum temperature of 40°F. In addition to protect the

cold water basin, all exposed water piping including

pump piping below the overflow level and makeup

water lines should be traced with electrical heater tape

and insulated.