Maintenance

Procedures

8

COLD WATER BASIN

The cold water basin should be inspected regularly. Any

trash or debris which may have accumulated in the basin

or on the strainers should be removed.

Each month, the entire cold water basin should be

drained, cleaned, and flushed with fresh water to remove

the silt and sediment which normally collects in the basin

during operation. If not removed periodically, this sedi-

ment can become corrosive and cause deterioration

of the protective finish. When flushing the basin, the

strainers should be left in place to prevent the sediment

from re-entering the system. After the basin has been

flushed, the strainers should be removed, cleaned, and

replaced before refilling the basin with fresh water.

CAUTION: Do not use acid to clean the strainers.

The operating water level in the cold water basin will vary

somewhat with system thermal load (evaporation rate),

the bleed rate employed and the make-up water supply

pressure. Because the typical winter load is less than the

summer load, the winter evaporation rate is frequently

less than the summer evaporation rate. With this reduced

evaporation rate in winter, the water level in the cold water

basin will increase unless the float is re-adjusted. The

operating water level should be checked monthly and

the float re-adjusted as necessary to maintain the rec-

ommended operating level.

The water level in the basin of equipment designed for

remote sump operation is a function of the circulating

water flow rate, water outlet connection size, quantity and

location, and outlet piping size and configuration. The

remote sump unit is supplied without a water make-up

assembly and the sump operating level during remote

sump operation is not adjustable.

MAKE-UP VALVE

A float operated mechanical water make-up assembly is

furnished as standard equipment on all Series V and Low

Profile Series V equipment unless the unit has been

ordered with the optional electric water level control pack-

age or for remote sump application. It is located inside the

unit cold water basin within easy reach from the access

door at the connection end of each unit.

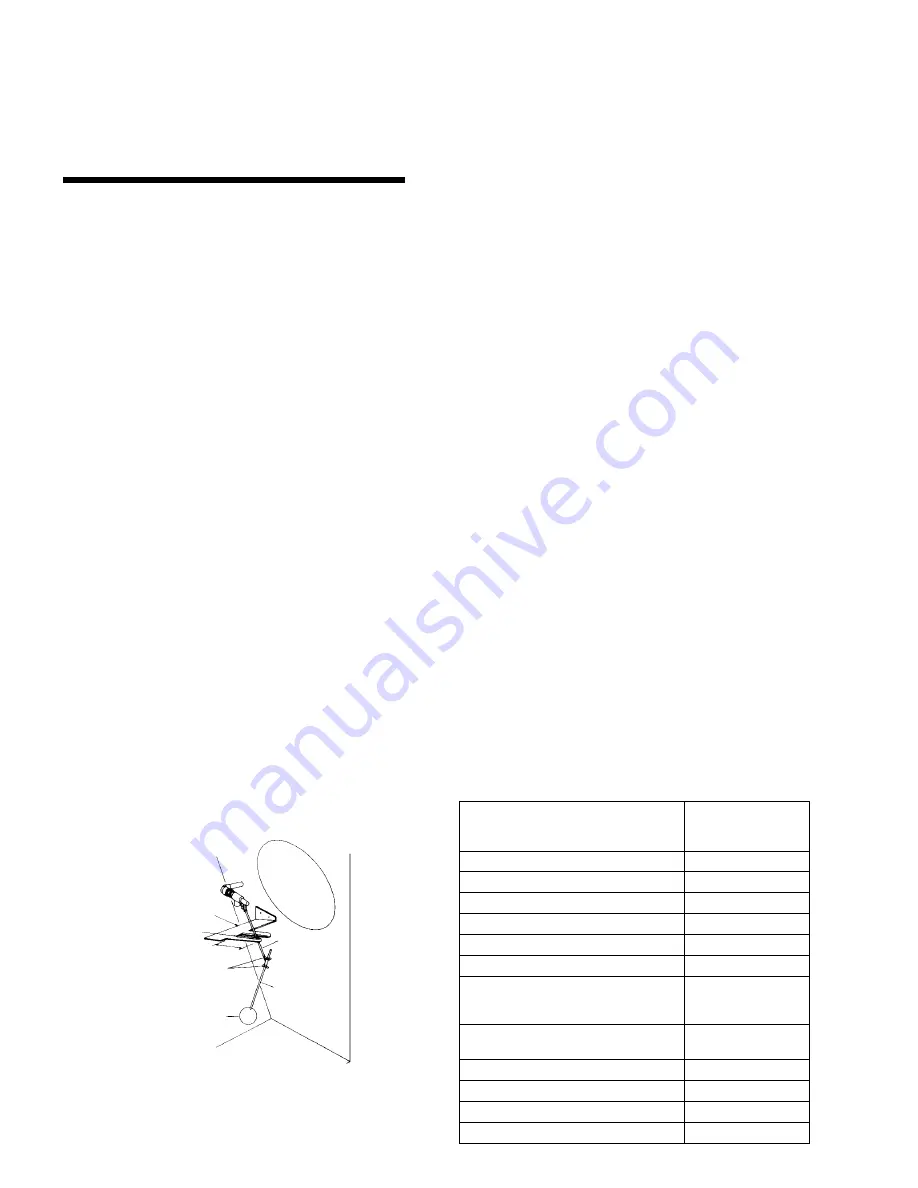

The standard make-up assembly (see Figure 1) consists

of a bronze make-up valve connected to a float arm

assembly and actuated by a large diameter polystyrene

filled plastic float. The float is mounted on an all-thread

rod which is held in place by wing nuts. The operating

water level in the cold water basin can be adjusted by

repositioning the float and all-thread rod using the wing

nuts provided.

The make-up assembly should be inspected monthly

and adjusted as necessary. The valve itself should be

inspected annually for leakage and the valve seat

replaced if necessary.

The make-up water supply pressure should be main-

tained between 15 and 50 psig for proper operation of

the valve.

To set the initial basin water level, adjust the wing nuts

so that the make-up valve is completely closed when the

water level in the cold water basin is 1/2” below the over-

flow connection. Under design thermal load and with aver-

age city water pressure (15 to 50 psig) at the valve, this

setting should produce the operating water levels stated

in Table 2. Note that if the thermal load is less than the

design load at the time of unit start-up, the procedure may

produce operating levels greater than that shown. It may

be necessary to re-adjust the float in order to attain the

recommended operating level. The unit basin should be

closely monitored and water level adjusted as necessary

during the first 24 hours of operation.

TABLE 2. Operating Water Level

Figure 1 – Water Make-Up Valve Assembly

Float Arm

Stop

Plastic U-Slip

Wing Nuts

Float Ball

Float Arm

Assembly

All Thread Rod

OPERATING

HEIGHT (measured

from basin bottom)

MODEL NO.

5

1

/

2

"

13

1

/

2

"

16

1

/

2

"

17

"

12

7

/

8

"

15

1

/

2

"

17

"

14

"

8

7

/

8

"

9

5

/

8

"

6

"

12

1

/

8

"

VTL, VFL, VCL

VF1-009 thru VF1-036, VC1-10 thru 135

VF1-048, VC1-150 thru 205

VF1-072, VC1-N208 thru N230

VTO-12 TO VTO-116

VTO-132 TO VTO-176

All VT1-N, VF1-096, VF1-144N,

VF1-192, VF1-288N, VC1-N243 thru

N470, VC1-C216 thru C469

All VT1, VTF1-144, VF1-216, VF1-288,

VF1-432, VC1-386 thru 1608

VC2-N138-N191

VC2-N206-N235

VC2-N261-N446

VC2-319-1774