INSTRUCTIONS FOR DETERMINING THE CAUSE LEADING TO IRREGULARITIES IN THE

OPERATION AND THEIR ELIMINATION

IRREGULARITY

Appliance locks out due to no flame

(red light lit).The fault is in the flame

control device.

The burner goes into “lock-out”, gas

flows, but there is no flame (red light

on).Fault in ignition circuit.

The burner goes into “lock-out”, gas

flows, but there is no flame (red light

on).

POSSIBLE CAUSE

- Disturbance to ionization current from the

ignition transformer.

- Flame sensor (ionization probe)

inefficient.

- Flame sensor (ionisation probe) position

incorrect.

- Ionization probe or relative ground cable.

- Electrical connection cut-off by flame

sensor.

- Inefficient draught or fumes passage

blocked.

- Flame disk or combustion heads dirty or

worn.

- Equipment fault.

- No ionization.

- Fault in ignition circuit

- Ignition transformer cable discharges to

earth.

- Ignition cable disconnected.

- Ignition transformer is faulty.

- The distance between electrode and

ground is incorrect.

- Insulator dirty, so electrode discharges to

ground.

- Air/gas ratio incorrect.

- Gas pipe has not been properly bled of air

(in the case of first ignition).

- The gas pressure is insufficient or

excessive.

- Air flow between disk and head too

narrow.

REMEDY

- Invert the ignition transformer power supply

(230V side) and check using an analogue

micro-ammeter.

- Replace the flame sensor.

- Correct the position of the flame sensor, and

then check its efficiency by connecting the

analogue micro-ammeter.

- Check visually and using the instrument.

- Restore the connection.

- Ensure that the boiler fumes passage and

chimney connection are free.

- Visually check and replace, if necessary.

- Replace it.

- If the “earth” of the equipment is not efficient,

do not check the ionization current.Check

the efficiency of the “earth” at the terminal

concerned in the equipment and at the “earth”

connection of the electric system.

- Check the ignition transformer power supply

(230V) and high voltage circuit (electrode

to earth or isolator broken under locking

terminal).

- Replace it.

- Connect it.

- Replace it.

- Position it at the correct distance.

- Clean or change the insulator or electrode.

- Correct the air/gas ratio (there is probably too

much air or very little gas)

- Bleed the gas pipe again, with due caution.

- Check the maximum gas pressure value at the

time of ignition (use a water pressure gauge,

if possible).

- Adjust the disk/head opening.

29 / 34

0006081328_202202

ENGLISH

Summary of Contents for 17530020

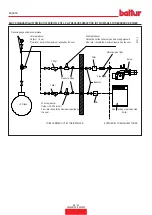

Page 2: ......

Page 32: ...SCHEMI ELETTRICI TBG 80 360LX ME TBG 80 360 ME 30 34 0006081328_202202 ITALIANO...

Page 33: ...TBG 80 360LX ME TBG 80 360 ME 31 34 0006081328_202202 ITALIANO...

Page 34: ...TBG 80 360LX ME TBG 80 360 ME I1 I2 BA I4 I3 32 34 0006081328_202202 ITALIANO...

Page 36: ...34 34 0006081328_202202 ITALIANO...

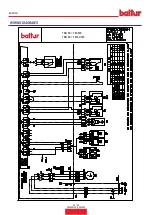

Page 66: ...WIRING DIAGRAMS TBG 80 360LX ME TBG 80 360 ME 30 34 0006081328_202202 ENGLISH...

Page 67: ...TBG 80 360LX ME TBG 80 360 ME 31 34 0006081328_202202 ENGLISH...

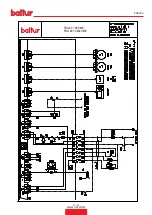

Page 68: ...TBG 80 360LX ME TBG 80 360 ME I1 I2 BA I4 I3 32 34 0006081328_202202 ENGLISH...

Page 70: ...34 34 0006081328_202202 ENGLISH...

Page 71: ......