ENGLISH

19 / 42

0006160060_201802

FIRST FILLING OF HYDRAULIC CIRCUIT

After checking that the protective plastic caps on the pump fittings

have been removed, proceed as follows:

• Turn the switch on the burner to the “O” position to avoid the burner

automatic activation.

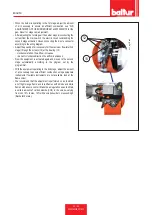

• Make sure, in case of a three-phase burner, that the motor revolves

anti-clockwise when watching it from the pump side. The rotation

direction can be determined also looking at the direction of fan

rotation through the inspection window on the back of the scroll.

To start up the motor, close the remote control switch manually

(by pressing on the mobile part) for a few seconds and watch the

sense of rotation of the fan. If it is necessary to change the direction

of rotation, invert two phases of the line input terminals (L1_L2_L3)

• Of it is necessary to reserve the direction of rotation, reverse two

phases on line input terminals contactor motor K1.

DANGER / CAUTION

To positively determine the direction of rotation, wait until the

fan turns very slowly because it is quite easy to misinterpret the

direction of rotation.

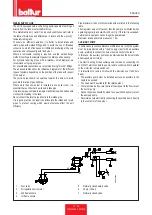

• Detach, if already attached, the flexible hoses from the intake and

return pipes.

• Dip the end of the suction hose into a vessel containing either

lubrication oil or diesel (do not use low viscosity products such as

petrol, kerosene, etc.).

• With fuel switch set to "OIL", move the on/off switch to position "I":

the programmer will thus start the burner.

• Wait until the pump has sucked an amount of lubricant equal to 1

or 2 glasses, then stop.

• This operation will prevent the pump from operating dry and will

increase the suction power.

DANGER / CAUTION

Pump operating at 2800 r.p.m. must not work dry otherwise

they will jam (seizure) within a very short time.

• Attach the flexible hose to the intake pipe and open any gate valves

fitted on this pipe and any other shut-off element on the fuel pipes.

• Return the on-off switch to position "I" to operate the burner and,

consequently, the pump will suck fuel from the tank. When fuel is

seen coming out of the return line (not yet connected), stop.

DANGER / CAUTION

If the pipe is long, it may be necessary to bleed the air out

through the cap; if the pump is not fitted with a cap, remove the

pressure gauge connector cap.

• Connect the return flexible hose to the return pipe and open the

gates fitted on this pipe. Now the burner is ready for lighting up.

STARTING UP AND REGULATION

Before starting up, make sure that:

• The correct type of fuel has been selected.

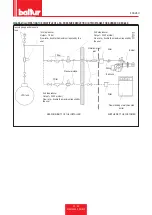

• Connections to the supply line, to thermostats or pressure

switches, have been made according to the electrical diagram of

the equipment.

• Check if there is fuel in the tank and water in the boiler.

• All the gate valves fitted on the fuel oil intake and return pipes are

open, as well as any other shut-off element on the fuel pipes.

• Make sure that discharge of combustion products takes place

freely (boiler and flue shutter open).

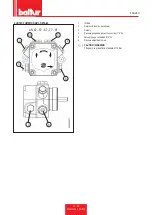

• Check that combustion head penetrates the combustion chamber

by the measure requested by the manufacturer of the boiler.

Check that the air closure device on the combustion head is in the

right position to guarantee a correct combustion, the air passage

between disk and head must be slightly reduced if a relatively small

amount of fuel is supplied. When the fuel supply is abundant the air

passage must be increased, see chapter "COMBUSTION HEAD

ADJUSTMENT”.

• Check that the nozzles fitted on the burner are suitable for the

boiler capacity. If necessary, replace them with suitable ones. In

no case should the quantity of fuel delivered exceed the maximum

amount required by the boiler and the maximum amount allowed

for the burner.

To start the burner proceed as follows:

DANGER / CAUTION

Prevent operation of the second flame avoiding to connect the

4-pin connector (2nd stage).

• Adjust the air in the amount presumed to be necessary for the

1st stage ignition using the special cam of the air adjustment

servomotor (indicative value 15° - 20°)

• Turn on the main switch and the one on the control panel.

• The programmer is activated and it starts carrying out the

predefined program activating the burner devices.The equipment

will start operation as described in the Chapter “DESCRIPTION

OF OPERATION”.

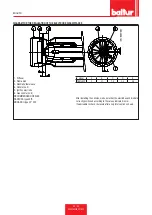

Summary of Contents for 56470010

Page 2: ......

Page 4: ...ITALIANO 2 42 0006160060_201802 ITALIANO Schemi elettrici 41 ...

Page 43: ...ITALIANO 41 42 0006160060_201802 SCHEMI ELETTRICI ...

Page 46: ...ENGLISH 2 42 0006160060_201802 ENGLISH Wiring diagrams 41 ...

Page 85: ...ENGLISH 41 42 0006160060_201802 WIRING DIAGRAMS ...

Page 87: ......