19 / 42

0006080764 _201312

0002933420

ENGLISH

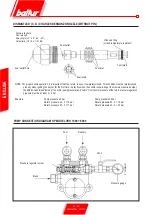

MODEL SPECIFIC GAS PILOT

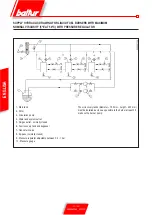

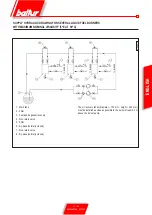

ADJUSTMENT PRINCIPLE DIAGRAM

dESCRIPTION OF OPERATION

WITH METHANE

The capacity variation range that can be reached goes approximately

from 1 to 1/5 in respect to the maximum capacity rate of the

appliance.

The burner is provided with a limit micro-switch that prevents the

ignition if the flow rate regulator is not at the minimum setting. In

accordance with safety standards, burner ignition is preceded by

a pre-ventilation stage of the combustion chamber. During the pre-

ventilation phase, the air and gas pressure servomotor detects the

air pressure and it reaches its maximum opening position. Therefore,

pre-ventilation is carried out with air inlet open at its maximum opening

position. From the above, the total pre-ventilation time is provided by:

air shutter opening time + pre-purge time + time for return of air

shutter to minimum position .

If sufficient pressure is detected by the ventilation air pressure

switch, the ignition transformer will cut in at the end of the ventilation

phase and later the pilot flame valves will open. Gas reaches the

combustion head, mixes with air supplied by the fan and is ignited.

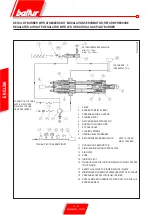

Flow is regulated by the flow regulator incorporated in one of the two

ignition flame valves (pilot). After the pilot flame valves have been

enabled, the ignition transformer cuts out.

The burner is thus operating on the pilot flame alone. Flame presence

is detected by the UV photocell. At this point the programmer relay

resets lockout position and supplies power to the main valves

causing them to open. The gas flows through the main valves and

out the combustion head in the amount permitted by the “minimum”

position of the flow regulator. The main flame of the burner is now

ignited at the minimum setting.

The pilot circuit cuts out after the main valves open.

The modulator servo-motor cuts in after the main valves open, and

on a consent signal from the modulating thermostat or pressure

switch (assuming they are set at a temperature or pressure value

in excess of the temperature or pressure in the boiler), the servo-

motor will start turning to provide a gradual increase in the supply

of gas and combustion air until the maximum nominal flow at which

the burner has been set is obtained.

Gas delivery is not determined by the main valve but by the

position of the gas distribution adjustment valve (see drawing

0002933530).

The burner remains in the maximum flow position until the

temperature or pressure are high enough to trip the modulation

probe, which reverses the rotation of modulation servomotor. The

inverse rotation and therefore the air and gas supply reduction

occurs shortly thereafter. With this procedure, the modulation system

attempts to balance the amount of heat supplied to the boiler with

respect to the amount the boiler releases for use. From this point

on, the modulation probe installed on the boiler measures any

variation requests and automatically adjusts fuel and combustion

air supply, by starting the modulation servomotor and increasing or

reducing rotation as necessary. If the threshold value (temperature

or pressure), to which the complete shut-down device (thermostat

or pressure switch) is set, is reached even with minimum gas and

air output, the burner will be shut down when the device is triggered.

When temperature or pressure returns below the shut-down device

tripping value, the burner is activated once again according to the

program described previously. If a flame is not detected within

the safety time, the control equipment goes into “lockout” mode

(complete shut down of the burner and illumination of the lockout

indicator light). To “resume” the equipment operation press the

dedicated button.

Summary of Contents for 66875410

Page 2: ......

Page 37: ...35 42 0006080764 _201312 ITALIANO schema elettrico...

Page 38: ...36 42 0006080764 _201312 ITALIANO...

Page 39: ...37 42 0006080764 _201312 ITALIANO...

Page 40: ...38 42 0006080764 _201312 ITALIANO...

Page 41: ...39 42 0006080764 _201312 ITALIANO...

Page 42: ...40 42 0006080764 _201312 ITALIANO...

Page 43: ...41 42 0006080764 _201312 ITALIANO RAMPA PILOTA RAMPA PRINCIPALE...

Page 46: ...2 42 0006080764 _201312 ENGLISH...

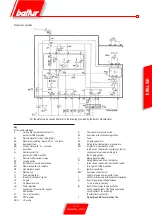

Page 79: ...35 42 0006080764 _201312 ENGLISH Wiring diagram...

Page 80: ...36 42 0006080764 _201312 ENGLISH...

Page 81: ...37 42 0006080764 _201312 ENGLISH...

Page 82: ...38 42 0006080764 _201312 ENGLISH...

Page 83: ...39 42 0006080764 _201312 ENGLISH...

Page 84: ...40 42 0006080764 _201312 ENGLISH...

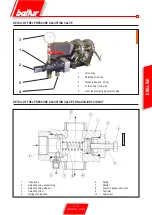

Page 85: ...41 42 0006080764 _201312 ENGLISH PILOT TRAIN MAIN TRAIN...

Page 87: ......