37

Opening of the 2nd stage valve allows the fuel (at a pressure of 25 bars) to reach the closure device of the 2nd

stage nozzle (n° 4/1).

The pressure of 25 bars (27 - 2 = 25) acts on the nozzle closure device of the 2nd stage which, up to a pressure

of 16 bars, stops fuel flowing to the second nozzle. This device is thus opened by the pressure itself and the

second nozzle starts working. A pressure of 25 bars now acts on the two nozzles. To read off the effective

pressure at the atomization unit and thus at the nozzles we recommend that you connect the pressure gauge

to the tank filter coupling (see drawing 0002932230).

NOTE

: It is evident from the above that the choice of nozzles, as a function of total desired flow-rate (2 nozzles

working), must be made by taking into account the flow-rates corresponding to a working pressure of 25 bars.

However, it is necessary to bear in mind that when the burner is working with the first stage only the fuel supply

rate is that which corresponds to one nozzle only as a function of 25 bars pressure.

It is obviously possible to vary the “relationship” between the first and the second stage extensively by changing

the nozzles. To ensure proper operation, always bear in mind that the fuel supply rate with the first stage must

never be less than the model-specific minimum flow-rate (see identification plate).

A lower flow-rate could make ignition difficult and combustion with the first stage only may not be good.

NOTE

: Some burner models have three nozzles (see drawing n° 0002900564). In this case there are two second stage

nozzles and both are subject to a pressure of 25 bars.

From the moment in which the flame appears in the combustion chamber the burner is controlled by the photoresistance

and the thermostats. When the temperature or pressure reaches the levels set on the thermostat or working pressure

switch that device will shut down the burner. The unit resumes normal operation automatically when the temperature/

pressure falls by the necessary amount.

If, for any reason, the flame goes out while the unit is working a (second) photoresistance cuts power to the power relay

switch and opens it; this switches off the n° 7 preventilation solenoid valve which opens and rapidly vents the existing

pressure. The atomized oil spray is intercepted by automatic closure of the nozzle shutdown devices on the atomizing

unit as soon as pressure falls below their settings.

In this case (with OR 3/B control box) the ignition stage is automatically repeated and, if the first stage is lit normally, the

burner starts working again normally too. If this is not the case (irregular or absent flame) the unit shuts down automatically.

With the LAL 1.25 control box an absent flame causes the burner to shut down without “attempting” a second ignition.

If the program is interrupted (power failure, manual work, tripped thermostat etc.) during the preventilation stage the

programmer goes to its home position and repeats the entire burner ignition sequence.

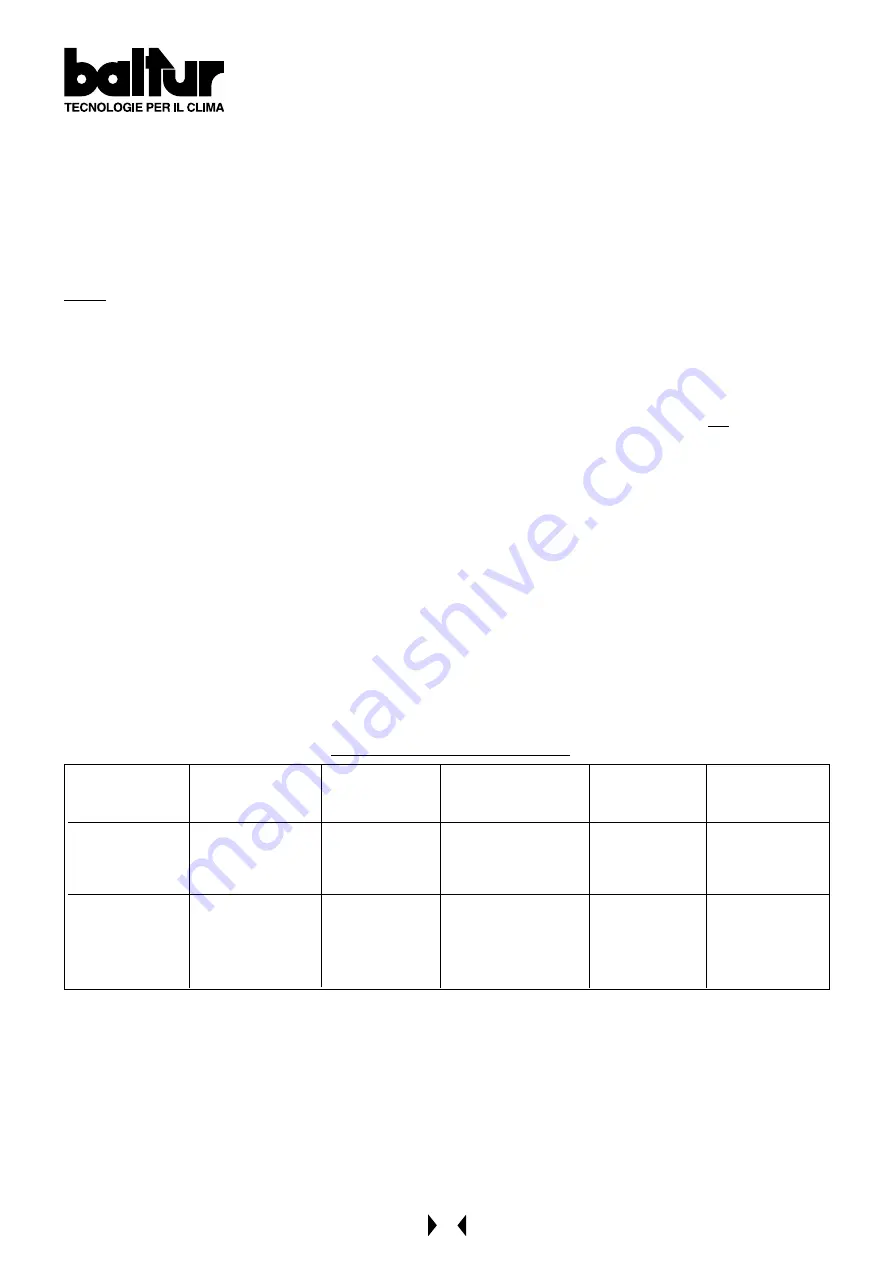

CONTROL BOX SPECIFICATIONS

Burner

Control box and

Safety time

Preventilation time

Post-ignition

Time between 1st

Model

relative programmer

in seconds

in seconds

in seconds

and 2nd stage

in seconds

BT 40 DSN - 4T

BT 55 DSN - 4T

OR 3/B

5

30

5

5

BT 75 DSN - 4T

LOA 44

5

25

5

5

BT 100 DSN - 4T

BT 120 DSN - 4T

BT 180 DSN - 4T

LAL 1.25

BT 250 DSN - 4T

5

22,5

15

7,5

BT 300 DSN - 4T

Cyclical relay

BT 350 DSN - 4T