10 / 22

98318_201204

00

02

90

06

01

pressure of 16 bar using diesel fuel. Bear also in mind that as the

burner is working with only the first flame activated, the first

nozzle fuel supply corresponds to the values indicated on the

10 bar table since the first flame pressure regulator is set to

this value. It is of course possible to vary within wide limits

the ratio between the first and the second flames by replacing

the nozzles. However, bear in mind that, in order to achieve a

proper operation, fuel supply using the first flame should not

be lower than the minimum capacity (indicated on the rating

plate) for the burner. A lower capacity could make ignition

difficult and the combustion obtained with the first flame alone

might not be optimal.

As the flame is present inside the combustion chamber,

the burner is controlled and monitored by the photocell and

thermostats. The programmer continues its travel and deactivates

the ignition transformer. The burner is lit working at full rate.

If the program is interrupted (due to a power supply failure, manual

action or the intervention of the thermostat, etc.) during the pre-

wash stage, the programmer returns to its starting position and

automatically repeats the entire burner ignition sequence.

When the temperature or the pressure reaches that set by the

thermostat or pressure switch, the burner stops.

The equipment resumes operation automatically as the temperature

or pressure value has reduced its value by the necessary amount.

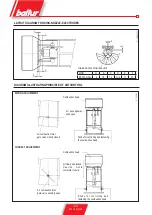

1 - Valve usually open

2 - Valve usually open

3 - Return

4 - Suction

5 - Foot valve

6 - Pump (16 bar)

7 - 1

st

flame pressure regulator (10 bar)

8 - Adjusting screw

9 - Air adjustment servomotor

10 - 2

nd

flame valve (13 bar)

11 - 1

st

flame valve (7 bar)

12 - 2

nd

flame nozzles

13 - 1

st

flame nozzle

If, during operation the flame is lacking for any reason, the photocell

activates immediately (one second) and stops the relay supply and

turns it off. Therefore, the washing solenoid valve deactivates and

quickly bleeds out the existent pressure and the diesel fuel atomised

spray is intercepted by the automatic closing of the atomiser unit

valve as soon as the pressure drops below 7 bar.

In this case, the ignition sequence is automatically repeated and,

if the flame re-ignites as usual, the burner starts working again as

usual, if not (irregular flame or fails to light completely) the equipment

goes automatically into lock-out.

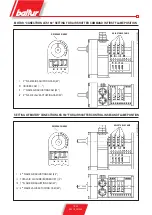

EQUIPMENT FEATURES

Equipment and

relative programmer

Safety time

in seconds

Pre-ventilation

and pre-wash time

in seconds

Post-ignition

in seconds

Time between 1

st

and 2

nd

flame

in seconds

LAL 1.25

Cyclic relay

5

22.5

15

7.5

HYDRAULIC DIAGRAM