11 / 22

98318_201204

FIRST FILLING UP OF PIPELINES

After making sure that the protective plastic caps inside the pump

fittings have been removed, proceed as follows:

1) Move the switch placed on the burner to the “0” position. This

operation prevents the burner from activating automatically.

2) Make sure, in case of a three-phase burner, that the motor

revolves anti-clockwise when you are watching it from the pump

side. The rotation direction can be determined also watching

the rotation direction of the fan through the inspection window

on the back of the scroll. To start the motor, close the remote

control switch manually (pressing on the mobile part) for a

few seconds and watch the rotation direction of the fan. If it

is necessary to reverse the rotation direction, reverse the two

phases on the line input terminals (L1 - L2 - L3).

Note:

To positively determine the rotation direction, wait until the

fan turns very slowly because it is quite easy to misinterpret

the rotation direction.

3) Disconnect the flexible pipes, if they have already been

connected, from both suction and return piping.

4) Immerse the end of the suction flexible pipe into a vessel

containing either lubricating oil or fuel oil (do not use low

viscosity products such as diesel fuel, petrol, gasoline,

kerosene. etc.).

5) Now press on the mobile part of the motor remote control switch

to start up the motor and the pump. Wait until the pump has

drawn 1 or 2 cups of lubricant, then stop. This will prevent the

pump from running dry and will increase the suction power.

Note:

Pumps operating at 2800 r.p.m. must not work dry otherwise

they will seize in a very short time.

6) Now connect the flexible pipes to the suction line and open

all the gate valves fitted on this line and any other similar fuel

cut-off device.

7) Now press on the mobile part of the motor remote control

switch to start up the pump that extracts the fuel from the tank.

When you see the fuel coming out of the return line (not yet

connected), stop.

Note:

If the piping is long, it may be necessary to bleed the air out

through the cap; if the pump is not fitted with a cap, remove

the cap from the pressure gauge.

8) Connect the return flexible pipe to the return line and open the

valves fitted on this pipe. Now the burner is ready for ignition.

IGNITION AND ADJUSTMENT

Before igniting the burner make sure:

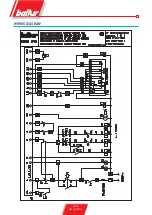

a) The feeding line connections to thermostats or pressure

switches are made exactly according to electric diagram of the

appliance.

b) There is fuel in the tank and water in the boiler.

c) All the gate valves fitted on the diesel oil suction and return

pipes should be open; the same thing applies to any other fuel

cut-off device.

d) The exhaust of combustion products takes place freely (boiler

and chimney gate valves open).

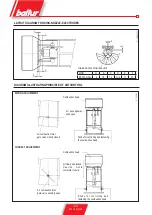

e) Make sure that the burner head penetrates into the combustion

chamber according to the instructions of the boiler manufacturer.

The burner is equipped with a coupling flange to the boiler,

which slides on the burner head.

f) The nozzles fitted on the burner should be suitable for the boiler

capacity; replace them with others, if necessary. Under no

circumstances should the delivered quantity of fuel exceed the

maximum amount required by the boiler and the max. amount

permitted for the burner. Bear in mind that the combustion head

has been designed for nozzles with a 45° spray angle.

Note:

To obtain a proper ignition and combustion using the first flame

alone, the fuel supply should not be considerably lower than the

minimum capacity (indicated on the plate) for the specific burner.

Note:

The burner has a switch to pass manually from the 1

st

to the

2

nd

stage.

To ignite the burner proceed as follows:

1) Disconnect the thermostat (if connected) to prevent second

flame activation.

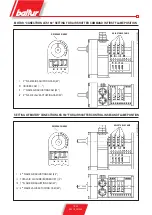

2) Slightly open the air regulator (0002904000 / 0002904010) and

let in an amount of air deemed necessary for burner operation

with the 1

st

flame and lock it in this position; set the air control

device in an intermediate position on the combustion head (see

chapter “Adjusting the air on the combustion head”).

3) Turn on the main switch and the equipment main switch.

4) The programmer activates and performs the pre-set program,

activating the devices of which the burner consists. The burner

ignites as described in chapter “Operation description”.

5) When the burner is operating with the 1

st

flame, adjust the

amount of air necessary to ensure an efficient combustion

(0002904000 / 0002904010). It is better if the amount of air

for the 1

st

flame is slightly reduced in order to ensure a perfect

ignition even in the most critical conditions.

6) After adjusting the air for the 1

st

flame the burner stops, cutting

off the voltage to the main switch. The terminals of the 2

nd

flame

thermostat terminal board connect and the first and second

stage switch moves to the second stage position.

7) Adjust the combustion air for the second flame (0002904000 /

0002904010)

8) The equipment activates again, it starts and automatically

switches to the 2

nd

flame established by the programmer

according to the pre-set program.

9) With the equipment operating with the 2

nd

flame, adjust

(0002904000 / 0002904010) the amount of air necessary to

ensure efficient combustion with the airflow necessary to ensure

good combustion. Subsequently check combustion with the

special instruments. In the absence of proper instrumentation

use flame colour as a guide. We recommend that the adjustment

is performed so as to obtain a soft light orange flame; avoid

red flames with smoke and white flames with an exaggerated

excess of air. The air regulator should be in a position to allow a

percentage of carbon dioxide (CO

2

) in the smoke, varying from