10 / 22

0006081529_201201

ENGLISHENGLISH

triggers instant “lock” stop of the burner. Release the burner

by pushing the appropriate button and readjust the pressure

switch to an adequate value to detect the existent air pressure

during the pre-ventilation phase.

12) The pressure switches for checking gas pressure (minimum

and maximum) prevent the burner from operating when gas

pressure is between the expected values. The specific function

of the pressure switches clearly reveals that the pressure

switch for controlling minimum pressure must use the contact

which is closed when the pressure switch detects a pressure

value above the value it is set to, while the pressure switch

for controlling maximum pressure must use the contact that

is closed when the pressure switch detects a pressure lower

than the value it is set to. Minimum and maximum gas pressure

switches must be set when the burner is tested. Setting depends

on pressure detected from time to time. Tripping of any of the

gas pressure switches (in the sense of opening the circuit) will

therefore prevent the equipment and therefore the burner from

working. When the burner is working (flame on), tripping the

gas pressure switches (opening the circuit) will shut down the

burner immediately. When testing the burner, it is very important

to check that the pressure switches are working properly. By

using the adjustment devices, it can be verified whether the

pressure switch that stops the burner actually operates (i.e.

opens the circuit).

13) Verify the flame detector operation as follows:

- disconnect the wire coming from the ionization electrode,

- Start up the burner;

- The equipment will complete the control cycle and after

two seconds will lock the burner due to the lack of ignition

flame;

- switch off the burner;

- Re-connect the wire to the ionization electrode.

This test should also be conducted with the burner already on;

the equipment should “lock” immediately when the wire from

the ionization electrode is disconnected.

14) Check the proper function of the boiler thermostats or pressure

switches (when triggered they must stop the burner).

!

Check that ignition occurs normally since if the mixer is

not positioned correctly, it may happen that the speed

of the delivery air is so high that ignition is difficult.

If this happens, the mixer must be shifted back by

degrees until it is in a position in which ignition occurs

normally, and this new position can be regarded as the

final position.

Remember that for the ignition flame, it is better to limit the

amount of air to the amount strictly indispensable to ensure

safe ignition even in the most difficult cases.

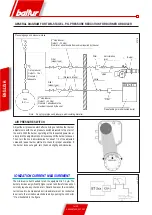

MANUAL BURNER OPERATION INSTRUCTIONS

Combustion may be checked throughout the entire modulation range

by controlling the “BT 3xx” equipment manually. Use the modulation

connector (A) as in the figure, supplied with the burner. Insert the

connector (A) into the 4-pole plug, use the + or - button to increase

or decrease the gas or air supply.

After completing the check, remove the connector (A) from the plug

to restore automatic modulation operation.

Summary of Contents for btg 15 me

Page 2: ......

Page 20: ...18 22 0006081529_201201 ENGLISH ENGLISH...

Page 21: ...19 22 0006081529_201201 ENGLISH...

Page 22: ...20 22 0006081529_201201 ENGLISH ENGLISH...

Page 24: ...22 22 0006081529_201201 ENGLISH ENGLISH...

Page 42: ...18 22 0006081529_201201 ESPA OL ESPA OL...

Page 43: ...19 22 0006081529_201201 ESPA OL ESPA OL...

Page 44: ...20 22 0006081529_201201 ESPA OL ESPA OL...

Page 46: ...22 22 0006081529_201201 ESPA OL ESPA OL...

Page 64: ...18 22 0006081529_201201 FRAN AIS FRAN AIS...

Page 65: ...19 22 0006081529_201201 FRAN AIS FRAN AIS...

Page 66: ...20 22 0006081529_201201 FRAN AIS FRAN AIS...

Page 68: ...22 22 0006081529_201201 FRAN AIS FRAN AIS...

Page 86: ...18 22 0006081529_201201 T RK E...

Page 87: ...19 22 0006081529_201201 T RK E...

Page 88: ...20 22 0006081529_201201 T RK E...

Page 90: ...22 22 0006081529_201201 T RK E...

Page 92: ...2 22 0006081529_201201 PYCCK BALTUR I a b c a b c d e f g...

Page 93: ...3 22 0006081529_201201 PYCCK 2 RC a b c d e a b a b c d I...

Page 100: ...10 22 0006081529_201201 PYCCK 12 13 14 BT 3xx...

Page 104: ...14 22 0006081529_201201 N 0002934540 Manutenz 2 Manutenz 1 Manutenz 3 PYCCK 3 4 1 2 3 3...

Page 106: ...16 22 0006081529_201201 8721 2 ioniz_BT3xx PYCCK 1 30 30 1 4 1 4 A...

Page 107: ...17 22 0006081529_201201 PYCCK 1 2 1 2 1 2 3 1 2 3 1 1 AD PE SS PN 40 40 1 2 3 4 18...

Page 108: ...18 22 0006081529_201201 PYCCK...

Page 109: ...19 22 0006081529_201201 PYCCK...

Page 110: ...20 22 0006081529_201201 PYCCK...

Page 112: ...22 22 0006081529_201201 PYCCK...

Page 113: ......