OPERATING DESCRIPTION

The gas train supplied is composed of an ON/OFF safety valve and a

single stage slow opening main valve.

The gas flow adjustment in the first and second stage is carried out by

a streamlined butterfly valve (6) activated by the electric servomotor

(7).

The movement of the air damper (8) is caused by the rotation of the

servomotor (7) through the lever and tie rod system (34). For the

adjustment of the air damper position according to the burner power

in the first and second stage, consult section: "IGNITION AND REGU

-

LATION". If when the main switch is turned on (1), the thermostats are

on, the voltage reaches the control box which starts the burner (2).

This turns on the fan motor (3) for pre-ventilating the combustion

chamber. At the same time the command servomotor (7) rotates, brin

-

ging the gas throttle (6) and the air damper (8), by means of a lever

system, to the opening position corresponding to the second flame.

The pre-ventilation phase comes only with the air gate in the second

flame position.

At the end of pre-ventilation, the gas throttle and the air damper are

returned to the ignition position, then the ignition transformer turns on

and the gas valves open.

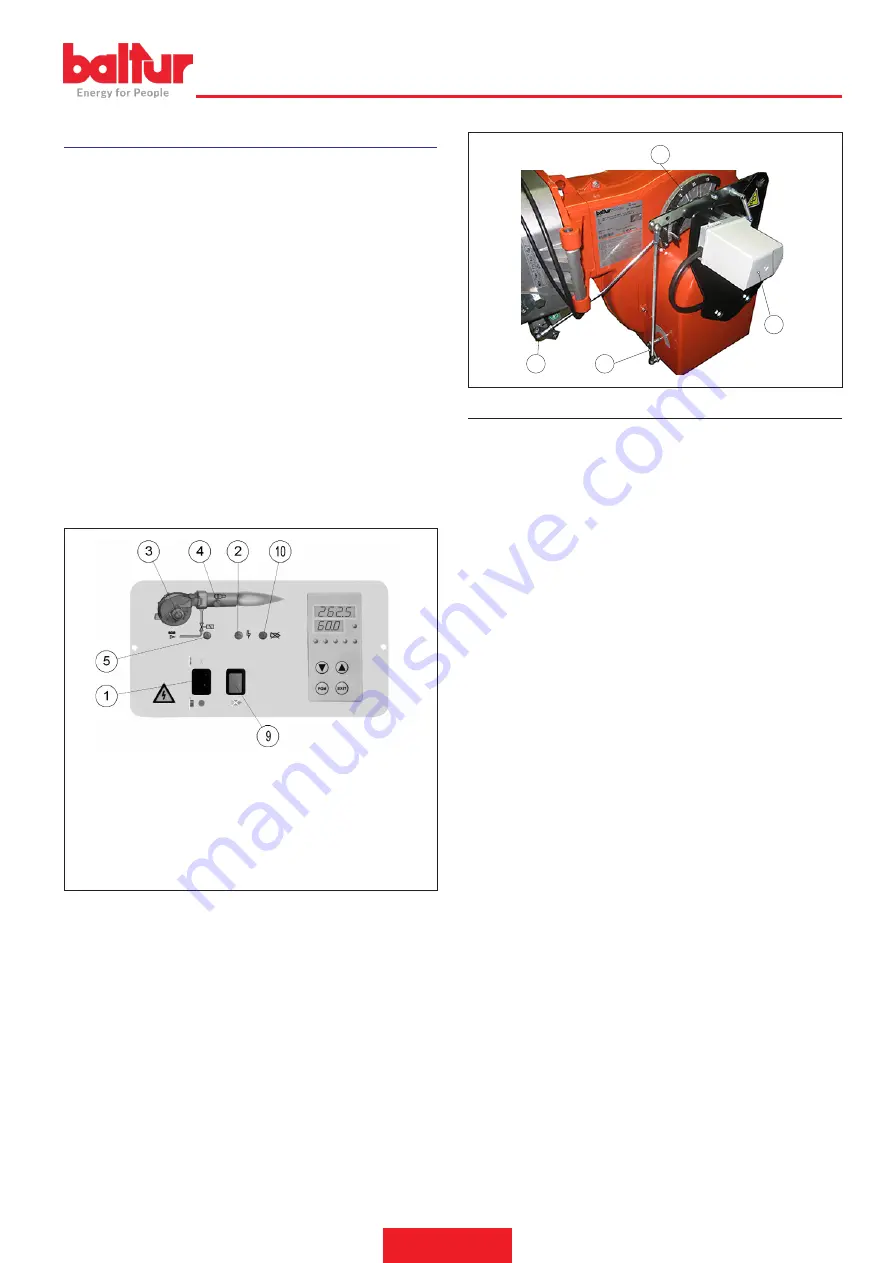

1 Main on/off switch

2 Thermostat on indicator light

3 Fan motor indicator light

4 Ignition transformer indicator light

5 Gas valves' indicator light

9 Reset button

10 Lock-out warning light

Then passing on to minimum or maximum power through the pro

-

gressive opening of the gas throttle and the air damper at the same

time.

At the moment in which the demand for heat from the system is sa

-

tisfied, the boiler thermostat will intervene and shut down the boiler.

The air damper, through the rotation of the servomotor, will reach the

closed position when inactive.

In the event that the control device does not detect the presence of

a flame, the control box activates a “safety lock-out” (10) within 3 se

-

conds of the opening of the main gas valve. In “safety lock-out” mode

the valves are immediately closed again. To release the equipment

from its safety position, press the reset button (9).

MotReg_

002

7

6

8

34

MODULATION OPERATION DESCRIPTION

When the burner is ignited at the minimum power, if the modulation

adjustment allows it (adjusted to a temperature or pressure which is

greater than that present in the boiler) the air/gas adjustment servo

-

motor begins to operate;

•

in a clockwise direction the air flow increases;

•

anticlockwise rotation: the air flow decreases.

causing a gradual increase in the combustion air and fuel flow, until it

reaches the maximum flow setting of the burner.

The burner remains in the maximum flow position until the tempera

-

ture or pressure is high enough to trip the modulation probe, which

reverses the rotation of the air adjustment servomotor.

Reverse rotation of the servomotor and consequently a reduction in

gas and air flow take place in short time intervals.

With this procedure, the modulation system attempts to balance the

amount of heat supplied to the boiler with respect to the amount the

boiler releases for use.

The modulation probe installed on the boiler measures any request

variation and automatically adjusts fuel and combustion air supply, by

starting the air/gas adjustment servomotor and increasing or reducing

rotation as necessary.

If the threshold value (temperature or pressure), to which the comple

-

te shut-down device (thermostat or pressure switch) is set, is reached

even with minimum gas and air output, the burner will be shut down

when the device is triggered.

When temperature or pressure returns below the shut-down device

tripping value, the burner is activated once again according to the

program described in the previous section.

ENGLISH

15 / 34

0006160008_201912

Summary of Contents for CE-0085BS0067

Page 2: ......

Page 35: ...SCHEMI ELETTRICI ITALIANO 33 34 0006160008_201912 ...

Page 69: ...WIRING DIAGRAMS ENGLISH 33 34 0006160008_201912 ...

Page 71: ......