36

STARTING UP AND REGULATION WITH METHANE GAS

1) If not already done at the moment of connecting the burner to the gas pipeline, it is indispensable to carry out

a purge of the air contained in the pipeline. As a precaution, special care should be taken and doors and

windows should be opened. Open the pipe union on the pipeline situated near the burner and the open a little

the gas cut-off cock (or cocks). When the characteristic odour of gas can be smelled, close the cut-off cock.

Wait until the gas present in the room has dispersed, and then reconnect the burner to the gas pipeline.

Subsequently, re-open the gas cut-off cock.

2) Check that there is water in the boiler and that the system’s gas valves are open.

3) Check, with absolute certainty that the discharge of combustion products can take place freely (boiler and

chimney lock-gates should be open).

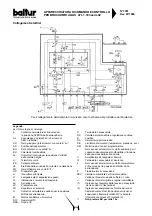

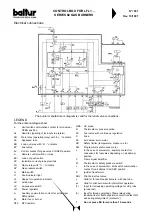

4) Make sure that the voltage of the electric line to which the burner is to be connected, corresponds to that

required by the burner and that the electrical connections (motor or principle line) have been prepared to

match the voltage rating available. Also check that all the electrical connections carried out on the spot are in

accordance with our electric wiring diagram.

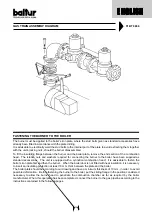

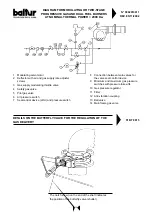

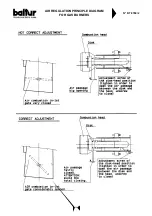

5) Make sure that the combustion head is long enough to enter the furnace to the extent specified by the boiler

manufacturer. Check that the device which regulates the air on the combustion head is in the position considered

necessary for the fuel delivery required (air passage between the disk and the head should be considerably

reduced when the fuel delivery is reduced; on the other hand, when the fuel delivery is fairly high; the air

passage between the disk and the head should be relatively open).

See chapter “Air Regulation on the Combustion Head”.

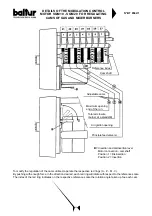

6) Apply a manometer with an adequate scale (if the entity of pressure forecast allows it; it is preferable to use

a column of water instruments, do not use a pointer instrument for moderate pressure) to the pressure plug

on the gas pressure switch.

7) Open, to the quantity considered necessary, the flow regulator incorporated in the ignition flame valve(s)

(pilot). Check that the combustion air regulation shutter is in the right position; if necessary, modify it by

operating the adjustable screws of the regulating disk.

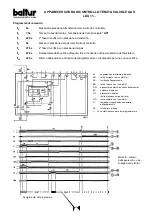

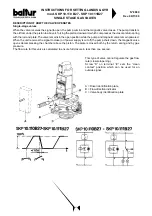

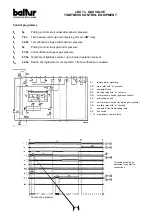

8) Remove the protective cover from the disk on which are inserted the screws which regulate the gas and air

delivery, and unloosen the locking screws.

9) With the switch on the burner’s control panel in the “O” position and the main switch inserted check by

manually closing the relay, that the motor rotates in the right direction. If it does not, exchange the places of

two cables of the motor’s supply line in order to invert its sense of rotation.

10) Now insert the switch on the commend panel and put the modulating switches in the MIN (minimum) and

MAN (manual) positions. The control box receives voltage in this way and the programmer turns on the burner

as described in Chapter “Description of Operations”.

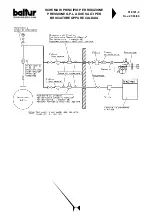

Note: Pre-ventilation is carried out with air open and, during this phase, the servomotor regulating the delivery

(gas/air) is inserted and completes the whole opening run until it reaches the “maximum” position. Subsequently,

the servomotor which regulates delivery (gas/air) returns to the starting position (minimum).

Only when modulation has returned to the “minimum” position, does the control box proceed with its ignition

programme and insert the transformer and the gas ignition valves for ignition.

During the pre-ventilation phase check that the air pressure switch effects a changeover (it should pass from

a closed position without measurement of pressure to a closed position with measurement of air pressure). If

the air pressure switch does not measure sufficient pressure (it will not effect the changeover) and neither the

ignition transformer nor the gas ignition flame valves will be inserted and the control box will go to “shut down”.

It should be pointed out that “shut downs” during the first ignition phase are considered normal. This is because

air still exists in the pipeline of the valve incline and must be expelled before it is possible to have a stable

flame. To unblock the control box, press the relative pushbutton.

UV CELL

If the flame detection is carried out with the UV cell, the following should be taken into consideration. Even the

slightest greasiness will compromise the passage of the ultraviolet rays through the UV photoelectric cell

bulb, thus preventing the sensitive internal element from receiving the quantity of radiation necessary for it to

function properly. Should the bulb be fouled by light oil, fuel oil, etc., it is indispensable to clean it thoroughly.

It should be pointed out that even by simply touching the bulb with the fingers, it is possible to leave a slight

greasiness which could compromise the working of the UV photoelectric cell.