37

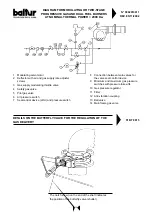

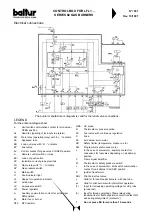

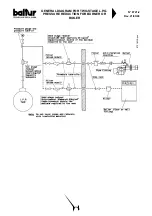

The UV cell does not “see” daylight or light from an ordinary lamp. It is possible to verify its sensibility with a

flame (or cigarette lighter or a candle) or with the electric spark that occurs between electrodes in an ordinary

ignition transformer. To ensure that the UV cell works properly, its current value should be sufficiently stable so

as not to fall below the minimum value required for the specific control box. It may be necessary to search

experimentally for the best position by sliding (axial or rotation movement) the body that contains the

photoelectric cell in respect to the fastening clamp. An inspection can be carried out by inserting a microammeter,

with an adequate scale, in series to one of the two UV photoelectric cell connection wires.

It is obviously necessary to respect the po and -). For the LFL.... control box, the value of the cell

current should be from 70 microamperes to 630 microamperes (the value is shown on the wiring diagram).

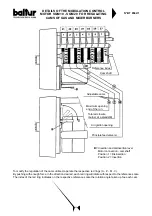

11) With the burner operating at a minimum (ignition flame valve and safety valve open and servomotor which

regulates delivery (gas/air) at a minimum), immediately check visually the entity and appearance of the flame

and, if necessary, proceed with correcting it by operating the gas delivery regulator of the ignition flame (pilot)

and/or the adjustable screws of the disk which regulates the gas and air delivery. Subsequently, check the

quantity of gas delivered by reading the meter. See Chapter “Reading the meter”. If necessary, correct the gas

and relative combustion air delivery by operating as described in point 7. The control combustion with the

appropriate instruments. For a correct air/gas ratio, the percentage of Carbon Dioxide (CO

2

) should increase

together with the increase in delivery. As an indication, for methane gas, the percentage should be from at

least 8 % at minimum burner delivery to an optimum value of 10 % for maximum delivery.

We advise against exceeding the value of 10 % to avoid operating with a rather limited excess of air which

could cause (variation in atmospheric pressure, presence of dust particles in fan’s air ducts) a considerable

amount of Carbon Monoxide (CO). It is indispensable to check, with the appropriate instrument, that the

Carbon Monoxide (CO) present in the smoke does not exceed the maximum level permitted of 0,1 %.

12) After having regulated at “minimum”, put the modulation switches in the “MAN” (manual) and “MAX” (maximum)

positions.

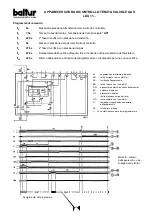

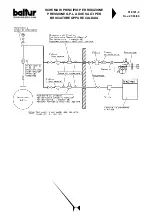

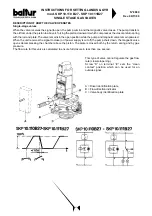

13) The servomotor regulating gas/air delivery starts up, the “V” cam contact closes (see BT 8562/1) and voltage

arrives at the principle gas valve which then opens. Wait until the disk on which the regulating screws have

been fitted, has reached an angle of about 12° (this corresponds to the space taken up by three screws), and

then stop modulation and return the switch to the “O” position. Carry out a visual control of the flame and

proceed, if necessary, with regulating the combustion air and the gas by operating the adjustable screws of

the regulating disk. The operation described above should be repeated progressively (by moving forward the

disk about 12° at a time) and modifying every time, if necessary, the fuel/air ratio during the whole modulation

run. Make sure that the increase in fuel delivery occurs gradually and that maximum delivery is reached at the

end of the modulation run. This is necessary in order to ensure that the modulation functions with good

graduality. The positions of the screws that commend the fuel may need to be modified in order to obtain the

graduality required.

14) With the burner operating at maximum delivery required for the boiler, check combustion with the appropriate

instruments and modify, if necessary, the previous regulation carried out after a visual control only

(CO

2

max. = 10 % - CO max. = 0,1 %).

15) We recommend controlling the combustion with the appropriate instruments and, if necessary, modify the previous

regulation carried out, after a visual control only, also in a few intermediate points of the modulation run.

16) Check that modulation functions automatically by putting the AUT - O - MAN switch in the “AUT” position and

the MIN - O - MAX switch in the “O” position. In this way, modulation is activated exclusively by the automatic

command of the boiler’s probe, if the burner is a modulating version, or on the command of the thermostat or

pressure switch of the 2nd stage, if the burner is a two-stage progressive version. (See Chapter “Electronic

Potentiality Regulator RWF 40 for the modulating version).

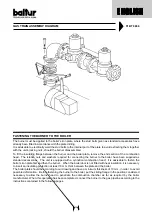

17) The air pressure switch

has the job of bringing the control box to a safety shut down if the air pressure is not at the correct value.

Therefore, the air pressure switch must be regulated in such a way as to intervene by closing the contact

(foreseen to be closed while working) when the air pressure in the burner has reached a sufficient level.

The pressure switch is self-controlled and therefore it must close the contact (fan stops and consequently

there is an absence of air pressure in the burner; if it does not, the control box will not be inserted (the burner

remains at a standstill). It must be specified that if the contact is not closed during working (insufficient air

pressure), the control box will carry out its cycle, but the ignition transformer will not be inserted and the gas

pilot valves will not open. Consequently, the burner will go to “shut down”. Check that the air pressure switch

functions properly with burner at minimum delivery, increase the regulating valve until it reaches intervention

point and the burner should go to shut down. To unblock the burner, press the special pushbutton and return

the pressure switch regulator to a sufficient value in order to measure the air pressure existing during the pre-

ventilation phase.