38

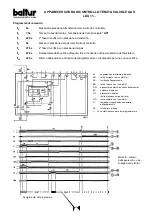

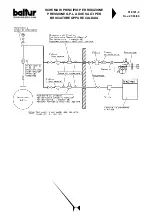

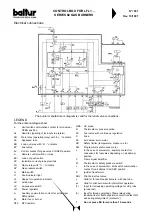

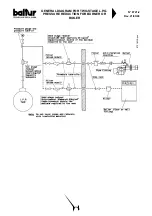

18) The pressure switches which control the gas pressure

(minimum and maximum) have the job of stopping the burner functioning when the gas pressure is not within

the values specified. From the specific functions of the pressure switches, it is evident that the pressure switch

which controls the minimum pressure must make use of the contact, which is closed, when it measures a

pressure which exceeds that at which it has been set. The maximum pressure switch must make use of the

contact, which is closed, when it measures a pressure below that at which is has been set.

The minimum and maximum gas pressure switches should be regulated during the burner’s general inspection

and should be in function with the pressure found each time. The pressure switches have been electrically

connected in series and therefore the intervention (by this mean the opening of the circuit) of any one of the gas

pressure switches, will prevent the control box and thus the burner from starting up. When the burner is

operating (flame lit), the intervention of the gas pressure switches (opening of the circuit) determines the

immediate arrest of the burner. During the burner’s general inspection, check the correct functioning of the

pressure switches. By operating the respective regulating device, it is possible to control the pressure switch’s

intervention (opening of circuit) which causes the burner’s arrest.

19) Check that the flame detector works by removing the UV photocell from its seat on the burner and

making sure LOCK-OUT shutdown occurs.

20) Check the efficiency of the boiler thermostats and pressure switches (this should result in the burner to a

standstill).

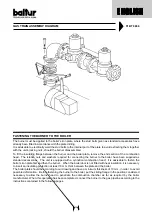

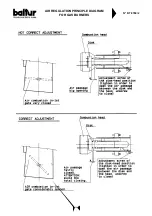

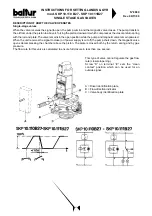

AIR REGULATION ON THE COMBUSTION HEAD

(See BT 8769/2)

The combustion head is equipped with a regulating device which closes (by moving forwards) and opens (by

moving backwards) the air passage between the disk and the head. By closing the passage it is possible to

achieve high pressure upstream the disk for low inputs as well. High velocity and air turbulence ensure a better

penetration in the fuel, an optimum mixture and good flame stability. It might be necessary to have high air

pressure upstream the disk in order to avoid flame pulsations and it is considered practically indispensable when

the burner is operating with a pressurized furnace and/or high thermal load. It is evident from the above, that the

device which closes the air on the combustion head should be put in such a position as to always obtain a

decidedly high air pressure value behind the disk. It is advisable to regulate in such a way as to achieve a closing

of the air on the head; this will necessitate a considerable opening of the air shutter which regulates the flow to the

burner’s fan suction. Obviously, these adjustments should be carried out when the burner is operating at maximum

delivery described. In practice, start regulating by putting the device which closes the air on the combustion head

in an intermediate position, start up the burner and make trial adjustments as previously described.

When maximum delivery desired has been reached, proceed with correcting the position of the device which

closes the air on the combustion head; move it backwards or forwards in such a way as to obtain an air flow

suitable to the delivery, with the air regulation shutter in suction considerably open. When reducing the air passage

on the combustion head, avoid closing it completely. Proceed with perfect centering with respect to the disk.

It must be pointed out that, if perfect centering with respect to the disk is not obtained, bad combustion and

excessive heating of the head could occur which would result in its rapid deterioration. A control can be carried out

by looking through the spy hole situated at the back of the burner; then tighten home the screws that lock the

position of the air regulation device on the combustion head.

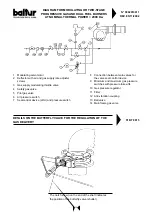

Note: Check that ignition occurs regularly, because when the device has been moved forwards, it could occur that

the air velocity in exit is so high as to render ignition difficult. If this happens, move it backwards, gradually,

until it reaches the correct position and ignition occurs regularly. This position should be definitive.

It should be kept in mind that it is preferable, for the first flame, to limit the amount of air to that strictly

necessary in order to ensure safe ignition even in difficult circumstances.

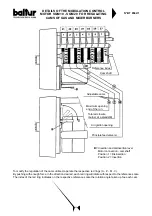

MAINTENANCE

The burner does not require special maintenance, but it is good practice to check periodically that the gas filter is

clean and that the ignition electrode is efficient. The combustion head may need cleaning and it will be necessary

to disassemble its components first. During re-assembling, special attention must be paid to avoid the electrodes

going to earth or short-circuiting, which would result electrodes going to earth or short-circuiting, which would

result in the “shut down” of the burner. It is also necessary to check that the spark of the ignition electrode occurs

exclusively between the ignition electrode and the drilled plate disk. To check the current of the UV cell, connect

a microammeter, with an adequate scale, “in series” to one of the two UV photo-electric cell connection wires.

It is obviously necessary to respect the polarity (+ e -).

The minimum value of the UV cell current should be between 70 microamperes and 630 microamperes.