8 / 87

0006081047_200802

E

N

G

L

I

S

H

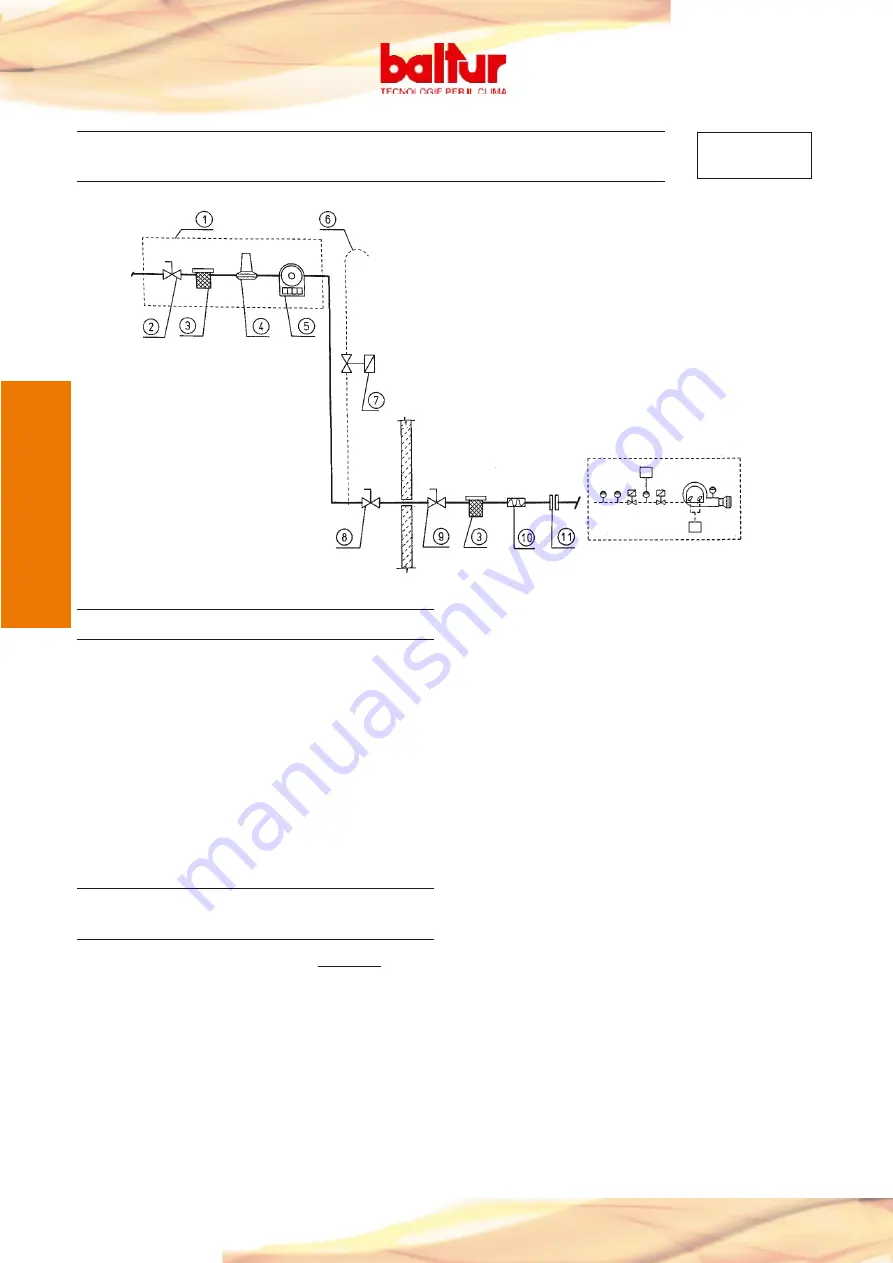

DIAGRAM OF CONNECTING A BURNER TI THE GAS PIPE NETWORK AT AVERAGE

PRESSURE

N° BT 8531/1

REV.: 15/11/1990

1 - Measuring and reducing unit

2 - Interception

3 - Filter

4 - Reducer

5 - Meter

6 - Wire gauze flame trap

7 - Eventual automatic overflow valve (it should obviously

unload outside in a suitable place)

8 - Emergency interception installed outside

9 - Ball cock

10- Anti-vibration joint

11- A couple of flange

GENERAL

These are forced-draught burners with gas/air mixtures

at the combustion head. They are suited to working with

forced-draught or low pressure burners according to the work cur

-

ves. They bring together great flame stability, total safety and a whole

new level of performance. The burner has a Lamtec electronic cam

(ETAMATIC model) controlled by a microprocessor for intermittent

running, for control and monitoring of gas draught burners with

electronic modulation and air-gas adjustment motors, as well as

possible fan motor inverters. When running as an automatic burner,

valve seal control is integrated into the system as is power regulation

and carbon monoxide levels (read the ETAMATIC instructions at the

end of the enclosed manual to better understand how it works).

DESCRIPTION OF OPERATIONS ON FLAME

MODULATION

The attainable capacity variation field is,

indicatively,

from 1 to

1/5 with respect to the maximum capacity stated on plate. Ignition is

preceded, as provided for in the regulations, by pre-ventilation of the

combustion chamber. The pre-ventilation stage for the combustion

chamber takes place with the air damper at the large flame position.

At the end of the pre-ventilation stage, the air combustion air damp-

ers are brought back to the ignition flame position. If the pressure

switch for the pre-ventilation air pressure shows sufficient pressure,

the ignition transformer is switched on and then the gas valves switch

on and the burner starts up.

The quantity of gas delivered (m

3

/h)

can be adjusted acting on the flow regulator of the SKP 25 valve.

The flame then appears, detected by the control device (UV photo-

electric cell) that permits completion of the ignition stage with the

switching off of the ignition transformer.

The pilot circuit switches off after the main valves have opened.

The burner is thus at the point of ignition (ZP, P0). The flame is de

-

tected by the infra-red detector. The programmer relay goes beyond

the lock-out position and causes the servo-motors to regulate the air

gas mix and the inverter is kept at minimum (P1). If the modulation

probe permits (adjusted to a temperature or pressure that is lower than

that in the boiler), the air-gas regulating servo-motors start to rotate

and cause a steady increase in the gas supply, the combustion air

and the motor’s revs increase to the maximum for which the burner

has been adjusted (P9).

N.B. The ETAMATIC electronic cam controls the burner by activating

the combustion air and gas servo motor as well as, where

used, the inverter for the fan motor according to a work curve

with 10 set points (see ETAMAC adjustment curve).

The burner stays at its maximum supply position until the tempe

-

rature or pressure reaches a sufficient level to activate the probe

that causes the air-gas supply regulation servo motors to turn in the

opposite direction to gradually reduce the gas supply, the correspon

-

ding combustion air and the number of motor revs (to minimum). If

the pressure or temperature limit is reached even at the minimum

delivery for which the full stop device is adjusted (thermostat or

pressure switch), the burner will be stopped by the action of the stop

device. By lowering the temperature or pressure below the level at

which the stop device intervenes, the burner is switched back on

at the previously described programme.

During normal working the modulation probe applied to the boiler

will detect the change in demand and automatically adjusts the

supply of combustion air by switching on the air-gas adjustment

servo motor with increased or decreased rotation. This operation

enables the air-gas delivery system to balance the amount of heat

Summary of Contents for GI 350 ME

Page 2: ......

Page 4: ......

Page 24: ......

Page 63: ......

Page 83: ...81 87 0006081047_200802 ...

Page 84: ...82 87 0006081047_200802 ...

Page 85: ...83 87 0006081047_200802 ...

Page 86: ...84 87 0006081047_200802 ...

Page 87: ...85 87 0006081047_200802 ЭЛЕКТРИЧЕСКАЯ СХЕМА GI 350 510 ME С ETAMATIC OEM ...