E

N

G

L

I

S

H

25 / 34

0006080766

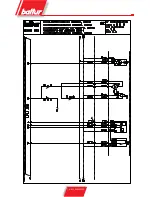

DETAILS OF THE MODULATION CONTROL MO-

TOR SQM 10 AND SQM 20 FOR REGULATION OF

CAMS

To modify the regulation of the 3 cams utilized, operate the

respective red rings ( A - Z - M ).

By pushing with enough force, in the direction desired, each red

ring will rotate with respect to the reference scale. The index of the

red ring indicates on the respective reference scale the rotation

angle taken up for each cam.

N°

B

T

85

62

/2

Reference Index

Camsshaft

Total air closure

(burner at a standstill)

Air ignition opening

B =

Insertion and disinsertion lever

motor connection Camshaft

Position 1 = Disinsertion

Position 2 = Insertion

Adjustable Cams

Maximum air

opening

end of the run

INSTRUCTIONS LFL 1.... CONTROL BOX

Control box for burners of average and high power, with forced

draught, intermittent service (*), 1 or 2 stages, or modulating

types, with supervision of the air pressure for controlling the

air damper.

This control box bears the EC mark, in accordance with the

Gas and Electromagnetic Compatibility Directive.

* For reasons of safety, it is necessary to make at least one con-

trolled stop every 24 hours!

As regards the standards

The following LFL1… features exceed the standards, offering

a high level of additional safety:

- The flame detector test and false flame test start immediately after

the tolerated post-combustion time. If the valves remain open, or

do not close completely after adjustment stops, a lock-out stop

is triggered at the end of the tolerated post-combustion period.

The tests will end only at the end of the pre-ventilation time of

the next start-up.

- The validity of working of the flame control circuit is checked each

time the burner starts up.

- The fuel valve control contacts are checked for wear during the

post-ventilation time.

- A built-in fuse in the appliance protects the control contacts from

any overloads that may occur.

As regards the burner control

- The equipment allows operation with or without post-ventilation.

- Controlled activation of the air damper to ensure pre-ventilation

with nominal airflows. Positions checked: CLOSED or MIN (po

-

sition of ignition flame on start-up); OPEN at the beginning and

MIN at the end of the pre-ventilation time. If the servomotor does

not position the air damper at the points described, the burner

does not start-up.

- Ionization current minimum value = 6mA

- UV cell current minimum value = 70mA

- Phase and neutral must not be inverted.

- Any place may be used for installation and assembly (IP40

protection).

Summary of Contents for GI MIST 1000 DSPNM-D

Page 36: ...75 84 0006080766 ...

Page 37: ...76 84 0006080766 ...

Page 38: ...77 84 0006080766 ...

Page 39: ...78 84 0006080766 ...

Page 40: ...79 84 0006080766 ...

Page 41: ...80 84 0006080766 ...

Page 42: ...81 84 0006080766 ...