36 / 44

0006080103_201309

INSTRUCTIONS FOR DETERMINING THE CAUSE LEADING TO

IRREGULARITIES IN THE BURNER OPERATION AND THEIR ELIMINATION

ENGLISH

MALFUNCTION NATURE

POSSIBLE CAUSE

REMEDIES

The equipment shuts the flame down (red

light lid) the fault is limited to the flame

control device.

1) UV photocell severed or fouled with smoke

2) Insufficient draft

3) UV photocell circuit severed

4) Fouled disk or opening

1) Clean or replace it

2) Check all the smoke ducts in the boiler and

in the chimney

3) Replace the equipment

4) Clean them

The burner goes to lock-out spraying fuel

but the flame does not ignite (Red lamp on).

The trouble is in the ignition device,

providing the fuel is in a good condition

(not polluted) with water or other

impurities) and sufficiently atomised.

1) Ignition circuit interrupted.

2) The ignition transformer leads discharge

to ground.

3) Ignition transformer leads not properly

connected.

4) Ignition transformer failure.

5) The electrode tips are not at the correct

distance.

6) Electrodes discharge to earth because they

are dirty or their insulation is cracked; check

also under the porcelain insulator clamps

1) Check the entire circuit

2) Replace them

3) Connect them

4) Replace

5) Return to the required position

6) Clean or, if necessary, replace

The burner goes into lock-out spraying

fuel but the flame does not ignite. (red

light on).

1) Pump pressure is not regular

2) Water in the fuel

3) Too much combustion air

4) Air passage between the disk and orifice

closed too much

5) Nozzle worn out or dirty

1) Adjust it

2) Remove it from the tank with a suitable

pump (never use the burner for this job).

3) Reduce the amount of combustion air

4) Correct the position of the combustion

head regulation

5) Replace or clean

The burner goes to lock-out without

spraying fuel (Red lamp on).

1) Missing phase

2) Electric motor inefficient

3) Gas oil not reaching the pump

4) No gas-oil in the tank

5) Gate valve on the suction pipe closed

6) Nozzle clogged

7) Motor (three-phase) rotates in the wrong

direction (see arrow)

8) Foot valve leaks or is jammed

9) Defective pump

10) Voltage too low

1) Check the supply line

2) Repair it or replace it

3) Check the suction pipe

4) Fill it up

5) Open it

6) Remove it and clean it thoroughly

7) Change one phase in the supply switch

8) Dismantle and clean

9) Replace

10) Contact the electric company

Noisy burner pump.

1) Pipe diameter too small

2) Infiltrations of air into the pipes

3) Dirty coarse filter

4) Excessive distance between the tank and

the burner or a lot of accidental leakage’s

(elbows, curves, choking etc.)

5) Perished hoses

1) Replace taking care to follow the relative

instructions

2) Check and eliminate such infiltrations

3) Remove and wash it

4) Rectify the entire length of the intake pipe

and shorten the distance

5) Replace them

Summary of Contents for GI MIST 350 DSPGM

Page 2: ......

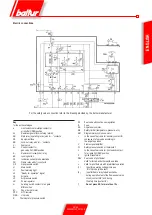

Page 40: ...38 44 0006080103_201309 WIRING DIAGRAM ENGLISH...

Page 41: ...39 44 0006080103_201309 ENGLISH...

Page 42: ...40 44 0006080103_201309 ENGLISH...

Page 43: ...41 44 0006080103_201309 ENGLISH...

Page 44: ...42 44 0006080103_201309 RAMPA PRINCIPALE ENGLISH...

Page 46: ...44 44 0006080103_201309 ENGLISH...

Page 84: ...38 44 0006080103_201309 ESPA OL ESQUEMA EL CTRICO...

Page 85: ...39 44 0006080103_201309 ESPA OL...

Page 86: ...40 44 0006080103_201309 ESPA OL...

Page 87: ...41 44 0006080103_201309 ESPA OL...

Page 88: ...42 44 0006080103_201309 ESPA OL RAMPA PRINCIPALE...

Page 90: ...44 44 0006080103_201309 ESPA OL...

Page 128: ...38 44 0006080103_201309 FRAN AIS SCH MA LECTRIQUE...

Page 129: ...39 44 0006080103_201309 FRAN AIS...

Page 130: ...40 44 0006080103_201309 FRAN AIS...

Page 131: ...41 44 0006080103_201309 FRAN AIS...

Page 132: ...42 44 0006080103_201309 FRAN AIS RAMPA PRINCIPALE...

Page 134: ...44 44 0006080103_201309 FRAN AIS...

Page 135: ......