8562/1

24 / 44

0006080103_201309

ITALIANO

USE OF THE BURNER

The burner operates fully automatically: it is activated

by switching on the main switch and the control panel

switch.

Burner operations are controlled by command and

control devices, as described in chapter “Operation

description”.

The “block” position is a safety position automatically

taken up by the burner when a particular part of the

burner or of the system is inefficient. Therefore, it

is good practice, before unblocking the burner and

starting it up again, to check that there are no defects

in the heating plant. The burner may stay in the lock

position without any time limits.

To unlock press the appropriate push-button (reset).

Blocks can be caused by transitory flows (a little water

in the fuel, air in the pipes, etc.); in these cases, if

unblocked, the burner will start up normally. When,

however, blocks occur repeatedly (3 or 4 times), do

not keep on trying to unblock the burner, first check

that there is fuel in the tank and then call the Technical

Assistance Service to repair the defect.

MAINTENANCE

It is recommended to carry out the following operations

at the end of the heating season.

• For burners which use diesel oil

:

remove the filters, nozzle, turbulator disc and

the ignition electrodes and clean thoroughly with

solvents (petrol, trilene, oil). Use wood or plastic

to clean the nozzle; avoid the use of metal tools.

• Clean the photocell.

• Have the burner cleaned and, if necessary, also

the chimney by specialized personnel (stove

repairer); a clean burner is more efficient, lasts

longer and is quieter.

• For gas burners,

periodically check that the gas filter is clean

.

• In order to clean the combustion head, its

components must be disassembled. Be careful

during the reassembly operations to exactly centre

the gas diffuser with regard to the electrodes,

making sure that they are not earthed, which

would result in the locking of the burner. It should

also be checked that the ignition electrode spark

occurs only between the electrode itself and the

perforated sheet disk.

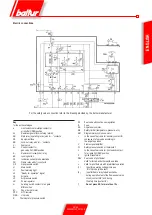

ADJUSTING THE MODULATION

CONTROL SERVOMOTOR

Use the corresponding red rings (A - Z - M - V ) to modify the adjustment of the 4 utilized

cams. Pushing with sufficient force in the desired direction, each (red) ring can turn

with respect to the reference scale. The pointer on each red ring indicates the rotation

angle set for each cam on the respective reference scale.

ENGLISH

Reference index

Camshaft

Adjustable cams

Maximum air opening

- end of stroke

Total air closure (burner off)

Ignition air opening

B =

Lever for inserting and

excluding the

motor - camshaft coupling

Position 1 = disabled

Position 2 = enabled

Main valve(s) power supply

Summary of Contents for GI MIST 350 DSPGM

Page 2: ......

Page 40: ...38 44 0006080103_201309 WIRING DIAGRAM ENGLISH...

Page 41: ...39 44 0006080103_201309 ENGLISH...

Page 42: ...40 44 0006080103_201309 ENGLISH...

Page 43: ...41 44 0006080103_201309 ENGLISH...

Page 44: ...42 44 0006080103_201309 RAMPA PRINCIPALE ENGLISH...

Page 46: ...44 44 0006080103_201309 ENGLISH...

Page 84: ...38 44 0006080103_201309 ESPA OL ESQUEMA EL CTRICO...

Page 85: ...39 44 0006080103_201309 ESPA OL...

Page 86: ...40 44 0006080103_201309 ESPA OL...

Page 87: ...41 44 0006080103_201309 ESPA OL...

Page 88: ...42 44 0006080103_201309 ESPA OL RAMPA PRINCIPALE...

Page 90: ...44 44 0006080103_201309 ESPA OL...

Page 128: ...38 44 0006080103_201309 FRAN AIS SCH MA LECTRIQUE...

Page 129: ...39 44 0006080103_201309 FRAN AIS...

Page 130: ...40 44 0006080103_201309 FRAN AIS...

Page 131: ...41 44 0006080103_201309 FRAN AIS...

Page 132: ...42 44 0006080103_201309 FRAN AIS RAMPA PRINCIPALE...

Page 134: ...44 44 0006080103_201309 FRAN AIS...

Page 135: ......