22 / 56

0006080405_201612

ENGLISH

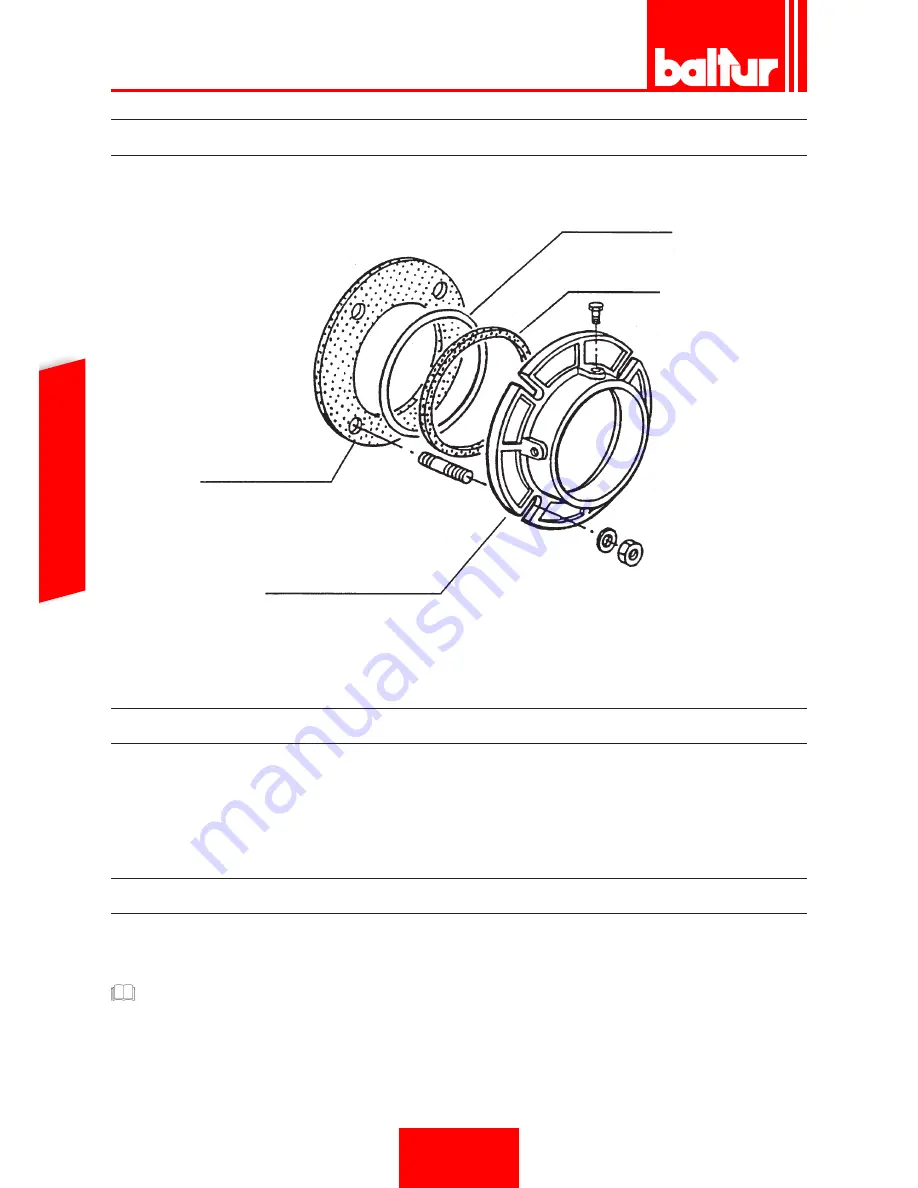

FITTING THE BURNER TO THE BOILER

The burner is fitted with a sliding attachment flange on the combustion head.

All the components supplied must be mounted following the burner instructions.

0002932730

Insulating flange

Aluminium flange

Sheet metalring

Insulating Cord

When the burner is being mounted on the boiler it is necessary to place this flange in the right position to have the

combustion head enter the combustion chamber according to the boiler manufacturer’s requirements.

Light oil pipes must be connected to the burner after it has been properly mounted on the boiler.

HYDRAULIC CONNECTIONS

The pipes that connect the tank tothe burner should be in perfect tight condition; we recommend the use of copper or steel pipes of an

adeguate diameter (see table and drawings).Fuel gate valves should be fitted at the end of the rigid pipelines.Fit the filter to the suction

pipeline after the gate valve. Connect the flexible fitting to this, which in turn should be connected to the suction of the burner pump. Connect

the flexible fitting to the return pipe after the gate valve, and then connect it ot the burner pump return. Filter, flexible pipes and relative

connecion nipples are standard burner accessories. The pump is provided with special connection points (see drawing 0002900480, and

0002900680) for the insertion of control instruments (manometer and vacuumeter).To ensure reliable and silent operating conditions, the

vacuum in suction should not exceed 35 cm Hg equal to 0,46 bar.Maximun suction and return pressure 1,5 bar.

ELECTRIC CONNECTIONS

The electrical lines should be at an adeguate distance from hot parts.It is advisable to make all the connections with flexible elecric wire.

Conductor’s minimun section 1,5 mm

2

.

The electric motor is equipped with thermal protector with automatic reset that stops the unit in case of overheating.

CAUTION / WARNING

In case of lock out it is necessary to check that the motor is not faulty and search for the possible causes of its heating.