STARTING UP AND REGULATION

•

Make sure that the mains voltage corresponds to the manufactu

-

rer's requirements and that all electrical connections made at the

installation site are effected properly as illustrated in our wiring

diagram.

•

Make sure that the combustion products may be freely vented

through the boiler and flue dampers.

•

Check that there is water in the boiler and that the gate valves of

the system are open.

•

Check that all the gate valves fitted on the fuel suction and

return pipes are open; the same applies to any other fuel shut-off

devices.

•

Bleed out the air contained in the gas piping, with due precautions

and with doors and windows open.

•

Open the union on the pipe near the burner and then open slightly

the gas shut-off cocks.

When the characteristic odour of gas can be smelled, close the cut-off

cock.

•

Wait the time necessary for the gas in the room to disperse outsi

-

de. Re-connect the burner to the gas pipeline.

•

Make sure that the combustion head is long enough to enter the

furnace following the measure specified by the boiler manufactu

-

rer.

•

Install a pressure gauge with adequate scale on the pressure

outlet of the gas pressure switch.

•

With the switch on the burner panel at the position “0” and the

main switch on, check, closing the contactor manually, that the

motor rotates in the right direction. If necessary, swap the two

power cables for the motor around to change the direction of

rotation.

•

If using the inverter, see the specific instructions in the quick

guide.

•

Turn on (position I) the switch (1) on the control panel to power

the equipment and close the thermostat line and turning the

selector (2) in the "closed" position.

•

If thermostats or pressure switches (safety and boiler) are closed

as well, the operating cycle will start.

•

The equipment turns on.

•

For the regulation of the burner, see “RAPID GUIDE TO PRO

-

GRAMMING” and the specific instruction manual for the electro

-

nic cam.

•

After setting the minimum load (200 digits), bring the burner up

to the maximum using the controls on the electronic cam keypad

and adjust all the points (from 200 digits to 999 digits) following

the regulation chart (see the electronic cam instructions in the

attached manual).

•

Check combustion using the appropriate instrument at all interme

-

diate points on the modulation route (from minimum to maximum

load), checking also the gas flow rate reading the meter.

•

Now, check for the efficiency of automatic modulation operation

by switching the ETAMATIC apparatus to the “AUTOMATIC”

position. With this setting the modulation function will start only by

using the automatic control of the boiler probe.

The air pressure switch stops the equipment operation if air pressure

is not at the expected value.

The pressure switch must therefore be adjusted so that it is triggered

to close the NO (normally open) contact when the air pressure in the

burner reaches the set value.

If the air pressure switch does not detect a pressure greater than that

calibrated, the equipment runs through its cycle but does not switch on

the ignition transformer and does not open the gas valves and so the

burner “locks-out”.

To ensure the air pressure switch correct operation, with burner at the

minimum output, increase the adjustment value until reaching the trig

-

gering value which must be followed by the immediate burner lock-out.

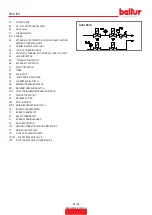

1

2

3

4

5

6

Display_BT320

1 Main ON/OFF switch

2 Thermostatic line switch

3 BT 320 Display

4 Equipment lock-out warning light

5 Voltage presence warning light

6 Fan lock-out, if foreseen

15 / 28

0006160509_202301

ENGLISH

Summary of Contents for TBG 1600 LX ME

Page 2: ......

Page 25: ...SCHEMI ELETTRICI 23 28 0006160509_202301 ITALIANO...

Page 26: ...24 28 0006160509_202301 ITALIANO...

Page 27: ...25 28 0006160509_202301 ITALIANO...

Page 28: ...26 28 0006160509_202301 ITALIANO...

Page 29: ...27 28 0006160509_202301 ITALIANO...

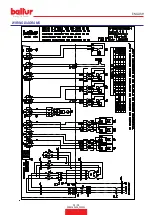

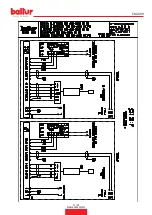

Page 53: ...WIRING DIAGRAMS 23 28 0006160509_202301 ENGLISH...

Page 54: ...24 28 0006160509_202301 ENGLISH...

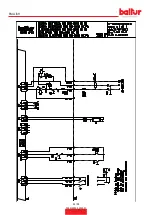

Page 55: ...25 28 0006160509_202301 ENGLISH...

Page 56: ...26 28 0006160509_202301 ENGLISH...

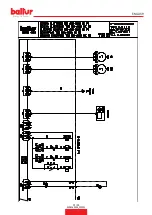

Page 57: ...27 28 0006160509_202301 ENGLISH...

Page 59: ......