ENGLISH

4 / 26

0006160227_201702

•

If there is any fault and/or if the equipment is not working

properly, de-activate the equipment and do not attempt to repair

it or tamper with it directly. Contact only qualified personnel.

•

Any product repairs must only be carried out by BALTUR

authorised assistance centres or its local retailer using only

original spare parts.

•

The manufacturer and/or its local retailer decline any liability

for injuries or damage caused by unauthorised modifications of

the product or non-observance of the instructions contained in

the manual.

SAFETY INSTRUCTIONS FOR INSTALLATION

•

The equipment must be installed in a suitable area with adequate

ventilation according to the standards and regulations in force.

•

The slots of the air extraction grilles and installation room

ventilation openings must not be obstructed even partially.

•

In the installation site there must NOT be any risk of explosion

and/or fire.

•

Thoroughly clean the inside of all pipes of the fuel supply

system before installation.

•

Before connecting the burner check that the details on the plate

correspond to those of the utility supplies (electricity, gas, diesel

or other fuel).

•

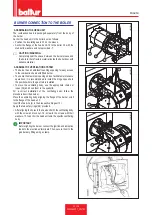

Make sure that the burner is firmly fastened to the heat generator

according to the manufacturer's instructions.

•

Make the connections to the power sources properly as indicated

in the explanatory diagrams and following the standards and

regulations in force at the moment of installation.

•

Check that the fume exhaust system is NOT obstructed.

•

If you decide not to use the burner any more, the following

procedures must be performed by qualified technicians:

- Switch off the electrical supply by disconnecting the power

cable from the main switch.

- Cut off the fuel supply using the shut-off valve and remove

the control wheels from their position.

- Render harmless any potentially dangerous parts.

INSTRUCTIONS FOR START-UP, INSPECTION, USE AND

MAINTENANCE

•

Start-up, inspection and maintenance of the equipment must

only be carried out by qualified technicians, in compliance with

current regulations.

•

Once you have fastened the burner to the power generator,

make sure that during testing the flame produced does not

come out of any slots.

•

Check for the seal of fuel supply pipes connected to the

equipment.

•

Check that the fuel flow rate matches the power required by

the burner.

•

Set the burner fuel capacity to the power required by the heat

generator.

•

The fuel supply pressure must lie between the values indicated

on the data plate located on the burner and/or in the manual

•

The fuel supply system is suitably sized for the flow required

by the thermal module and that it has all the safety and control

devices required by current standards.

•

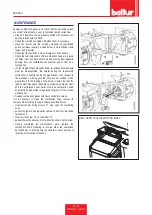

Before starting up the burner, and at least once a year, have

qualified technicians perform the following procedures:

- Set the burner fuel capacity to the power required by the

heat generator.

- Check the combustion adjusting the comburent and/or

fuel air flow to optimise the combustion performance and

emissions according to the regulations in force.

- Check the regulation and safety devices are working

properly.

- Check for the correct operation of the combustion products

exhaust duct.

- Check for the seal of fuel supply pipes in their internal and

external parts.

- At the end of the adjustment procedures, check that all

the mechanical locking devices of regulation systems are

properly tightened.

- Make sure that the burner use and maintenance manual are

available and within your reach.

•

If the burner repeatedly shuts down in lock-out, do not keep

trying to manually reset it but call a qualified technician to solve

the unexpected problem.

•

If you decide not to use the burner for a while, close the valve or

valves that supply the fuel.

Summary of Contents for TBG 2000 ME

Page 2: ......

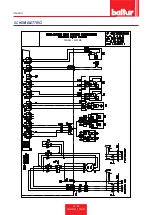

Page 24: ...ITALIANO 22 26 0006160227_201702 SCHEMI ELETTRICI TBG 480 2000 ME ...

Page 25: ...ITALIANO 23 26 0006160227_201702 TBG 480 2000 ME ...

Page 26: ...ITALIANO 24 26 0006160227_201702 TBG 480 2000 ME ...

Page 27: ...ITALIANO 25 26 0006160227_201702 TBG 480 2000 ME ...

Page 50: ...ENGLISH 22 26 0006160227_201702 WIRING DIAGRAMS TBG 480 2000 ME ...

Page 51: ...ENGLISH 23 26 0006160227_201702 TBG 480 2000 ME ...

Page 52: ...ENGLISH 24 26 0006160227_201702 TBG 480 2000 ME ...

Page 53: ...ENGLISH 25 26 0006160227_201702 TBG 480 2000 ME ...

Page 55: ......