ENGLISH

25 / 35

0006081444_201610

FREQUENCY CONVERTER

INVERTER TECHNICAL CHARACTERISTICS

Power supply voltage: 230 Vac 50/60 Hz single-phase

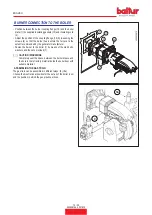

N. 3 adjustment buttons

N.4 green LEDs indicating the usual motor rotation speed level

(Vs, V1, V2, V3)

N.8 red LEDs indicating the frequency value of the output signal in

relation to the usual speed level.

N. 1 230 Vac digital output through clean contact

PC connection for diagnosis and parameter setting through

EEPROM serial port for saving the operating parameters and

storing alarms/faults.

Minimum working frequency: 18 Hz

Maximum working frequency: 50 Hz

INSTRUCTIONS FOR ADJUSTING THE MOTOR ROTATION

SPEED

The inverter allows the adjusting of three rotation speeds for the

motor-fan:

•

Vs level (factory setting: 30 Hz): rotation speed in relation to the

burner ignition stage

•

V1 level (factory setting: 25 Hz): rotation speed in relation to the

first stage of operation

•

V2 level (factory setting: 50 Hz): rotation speed in relation to the

second stage of operation.

•

Level 3: to be ignored for TBG 45/60 PV models.

It is not possible to adjust V2 to a lower value than V1 and Vs.

To adjust the output signal frequency in relation to the 3 speed

levels it is necessary to enter into programming mode by holding

down the SET key for a few seconds until the LEDs start flashing.

Having entered programming mode, the green led related to Vs

will begin to flash; it is now possible to adjust the motor rotation

speed value in Vs by pressing the + key to increase the speed

value or the - key to reduce it, as many times as necessary.

Every press on the + o - keys corresponds to an increase or

decrease of 0.2 Hz to the inverter output signal.

To quickly change the frequency hold one of the two the buttons

down for a prolonged period (maximum 16 seconds).

The motor follows the adjustment by increasing or decreasing

rotation speed in relation to the frequency set.

The frequency value is displayed approximately by the number of

flashing red leds.

With each increase of 4 Hz in the output frequency signal an

additional led will light up (see table 1).

The table represents the intervals in which the set frequency

(INVERTER) can be found, in relation to the number of lit red leds.

Having finished the speed adjustment in Vs, press the SET key for

about 2 seconds to go to the usual speed level in V1: the green

LED corresponding to V1 in the figure is flashing.

At this point the same procedure described above is repeated to

adjust in sequence the motor rotation speed in V1 and V2, while

V3 is ignored for TBG 45/60 PV models.

Having finished the adjustment for the three speed levels, exit

programming mode by pressing the SET key again for a few

seconds until the LEDs stop flashing.

The parameters set for the three levels are then stored.

In the event the SET key is not pressed, the inverter will

automatically exit programming mode after 30 minutes.

During operation the LED window displays the burner's operating

status: if the burner is operating in first or second stage, or it is in

the ignition stage the relative green led lights up and a number

of red LEDs according to the frequency of the signal the motor is

receiving in that moment which determine its rotation speed.

To perform adjustments and precise frequency readings of the 3

speed levels it is necessary to interface the inverter with the PC

by connecting them via the serial port using the appropriate cable,

which can be provided by the manufacturer on request.

Summary of Contents for TBG 45 PV

Page 2: ......

Page 36: ...ITALIANO 34 35 0006081444_201610 SCHEMI ELETTRICI...

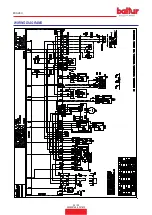

Page 71: ...ENGLISH 34 35 0006081444_201610 WIRING DIAGRAMS...

Page 73: ......