9 / 15

0006081370_200807

E

N

G

L

I

S

H

DESCRIPTION OF OPERATIONS AT TWO STAGE

PROGRESSIVE

These burners are of the blown air type which have a mixture of

gas/air at the combustion head. They are suitable for use with

combustion chambers which are either raising high pressure or

reducing pressure, according to the relative work curves. Together

with excellent flame stability, these burners are safe and highly

efficient. It is equipped with a steel flange which slips on the bur

-

ner head. When fastening the burner to the boiler it is necessary

to correctly position the flange so that the burner head enters the

combustion chamber to the extent specified by the boiler ma

-

nufacturer.The burner has an electronic cam mod. MPA22. The

microprocessor-controlled MPA22 provides intermittent operation,

controls and monitors the electronically-modulated fan-equipped

gas burners and features two (air/gas) adjuster motors. When wor

-

king as an automatic burner valve seal control is activated; (for a

better understanding of the MPA 22 read the instructions in the

attached manual, code 0006080905).

Operation of is of the progressive two-stage type, so called becau

-

se the switch from primary flame to secondary flame (from mini

-

mum to the set maximum) occurs gradually as regards the delivery

of both combustion air and fuel; this gives considerable advanta

-

ges in terms of the pressure stability in the gas feed line. Delivery

rate ranges, approximately, from 1 to 1/3. Ignition is preceded by

pre-ventilation of the combustion chamber as per standards, with

the air open: this lasts about 36 seconds. If, at the end of the ven

-

tilation stage, the air pressure switch detects that pressure is suffi

-

cient, the ignition transformer comes on and, after 3 seconds, the

safety and main valves open in sequence. The gas reaches the

combustion head, is mixed with the air being delivered by the fan,

and is ignited. Delivery is regulated by the gas throttle valve. Three

seconds after the (main and safety) valves are opened the ignition

transformer is switched off. The burner is now on at the ignition

point (P0). The flame is detected by the relative control device (an

ionisation sensor positioned inside the flame).The programming

relay goes beyond the shutdown position and powers the air/gas

delivery regulation servomotors, which go to minimum (P1). If the

2nd stage boiler thermostat (or pressure switch) – adjusted by a

temperature or

pressure greater than that in the boiler) allow, the air/gas delivery

servomotors start running and cause a gradual increase is the de

-

livery of gas and combustion air until the maximum flow rates to

which the burner has been set have been reached (point P9).

N.B. Electronic cam MPA22 controls the burner by adjusting

the combustion air and gas servomotors according to a pre-

set curve.

The burner remains in the maximum delivery position until the tem

-

perature or pressure reaches the limit set for the intervention of the

boiler thermostat (or pressure switch) of the 2nd stage and makes

the servomotors regulating gas/air delivery rotate in the opposite

sense of direction. Thus gas delivery and the relative combustion

air are gradually reduced until they reach minimum value.

Even with delivery at a minimum, if the limit (temperature or pres

-

sure at the shut down device (thermostat or pressure switch) has

been regulated is reached, the burner will be brought to a stan

-

dstill. When the temperature or pressure drops below the inter

-

vention limit set on the shut down device, the burner will star up

again, according to the programme previously described. During

normal operations, the boiler thermostat (or pressure switch) of

the 2nd stage fitted to the boiler detects the variations requested

and automatically proceeds with adapting the fuel and combustion

air delivery by inserting the servomotors which regulates delivery

(gas/air). This will rotate in such a way as to obtain an increase or

a decrease. With this manoeuvre, the gas/air delivery regulating

system try’s to equilibrate the quantity of heat supplied to the boiler

with that which the boiler gives to be utilised.

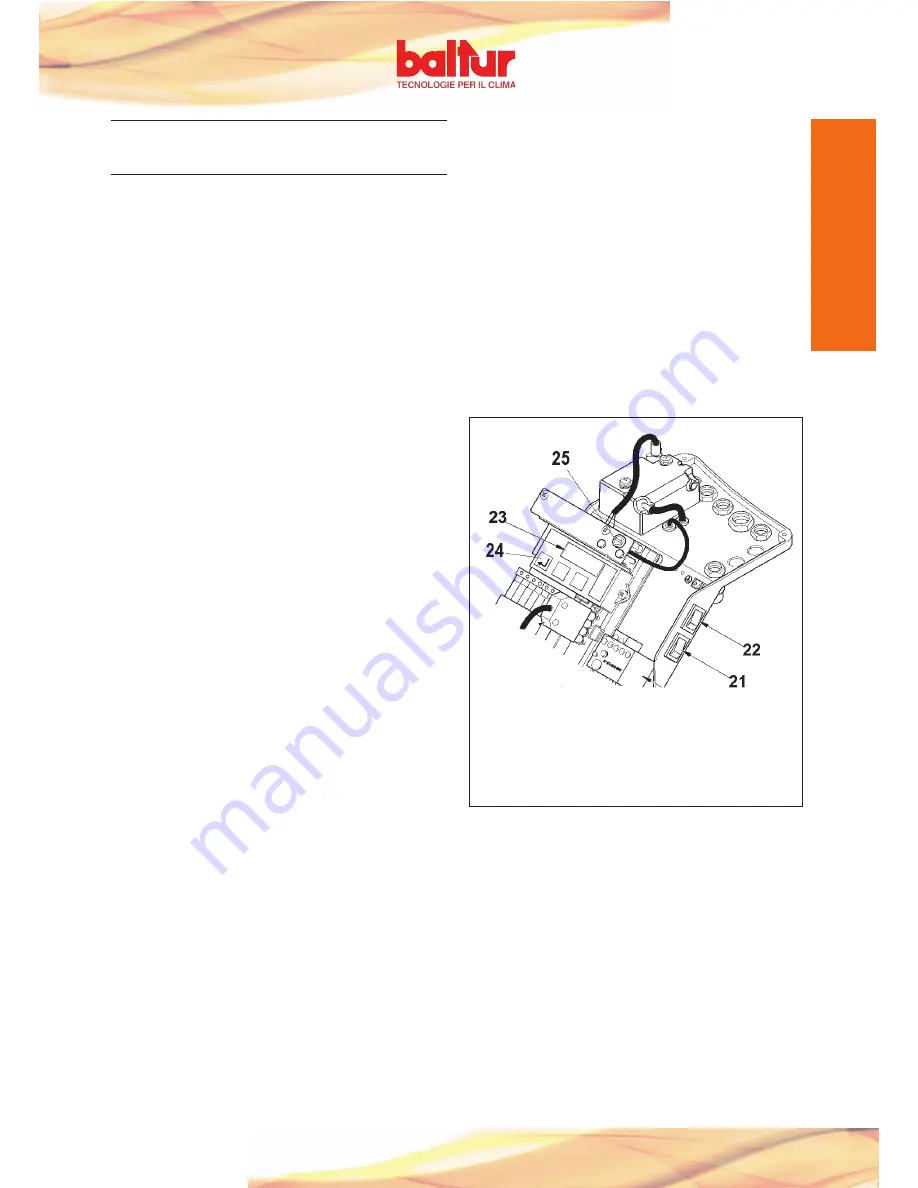

If the flame does not appear within THREE seconds of the opening

of the gas valve, the control box goes to “shut down” (the burner

stops completely and error message 25H) on display. (23)

To “unblock” the equipment press the interference elimination but

-

ton for about half a second (24).

0002935870n1

21) Thermostatic line switch

22) START/STOP switch

23) Display MPA22

24) Confirm or interference recovery key

25) Fuse

Summary of Contents for TBG 45ME

Page 2: ......

Page 4: ......

Page 6: ......

Page 22: ......

Page 38: ......

Page 54: ......

Page 70: ......

Page 86: ......

Page 102: ......

Page 103: ...97 101 0006081368_200807 ...

Page 104: ...98 101 0006081368_200807 ...

Page 105: ...99 101 0006081368_200807 ...