E

N

G

L

I

S

H

10 / 18

0006081041_201102

TBG 55P -210P

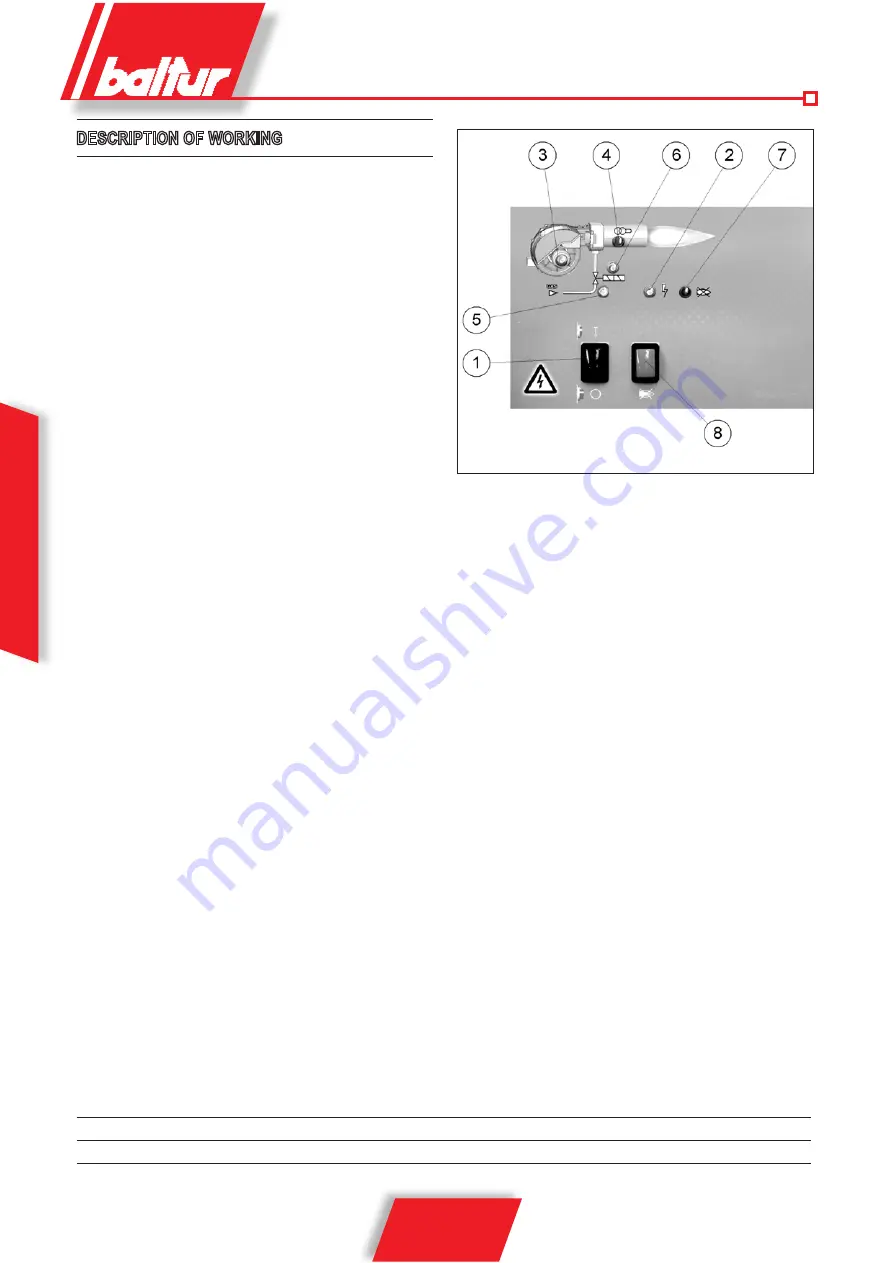

Closing switch 1, if the thermostats are closed, the voltage

reaches the command and control equipment (switching

on of LED 2) which starts it working. The fan motor is thus

switched on (LED 3) to carry out the preventilation of the

combustion chamber, at the same time the air damper

control servomotor moves to the opening position corre

-

sponding to the second flame, thus the preventilation takes

place with the air damper in second flame position.

At the end of the preventilation stage the air damper goes

back to the first flame position and then the ignition tran

-

sformer switches on (LED 4) and, after 2 seconds, the gas

valves (LED 5).

Note that:

a) The main two-stage valve has a device to adjust gas

supply to the first (LED 5) and to the second flame (LED 6).

b) The safety valve is an ON/OFF type.

c) The air damper is activated by an electric servomotor

(see adjustment page 69), remember that when the burner

stops because the thermostat is triggered, the damper is

moved by the servomotor back to its closed position.

The flame’s presence is detected by control device and al

-

lows the equipment to proceed to the ignition stage with the

switching off of the ignition transformer. Subsequently the

second flame switches on (increase of combustion air and

opening according to the main second stage valve LED 6)

If there is no flame, the equipment stops at “safety lock-out”

(LED 7) within 3 seconds from the first flame opening of the

main valve.

If there is a “safety lock-out”, the valves immediately close

again.

To release the equipment from its safety position you have

to press button 8 on the display panel.

DESCRIPTION OF WORKING

TBG 55

Closing switch 1, if the thermostats are closed, the voltage

reaches the command and control equipment

(switches on LED 2) which start it working. The fan motor is

thus switched on (LED 3) to carry out the

preventilation of the combustion chamber.

The ignition transformer is then switched on (LED 4) and,

after 2 seconds, the gas valves .

In particular:

a) The main two-stage valve has a device to adjust gas

supply to the first (LED 5) and second flame (LED 6).

b) The safety valve is an ON/OFF type.

c) The combustion air can be manually regulated by means

of a gate (see page 41). Bearing in mind the burner is an

ON/OFF type, the position in which the air damper must be

regulated is that necessary for working at maximum desired

supply.

The presence of the flame is detected by the detection

device and allows the equipment to go on to the completion

of the ignition stage with the ignition transformer off. Sub

-

sequently the second flame (LED 6, opening of the second

main stage valve).

If there is no flame, the equipment stops at “safety lock-out”

(LED 7) within 3 seconds from the first flame opening of the

main valve.

If there is a “safety lock-out”, the valves immediately close

again.

To release the equipment from this safety position you have

to press button 8 on the display panel.

Equipment or

Safety

Preventilation

Pre-

Post

-

Opening time

time travel

time travel

programmer

time

time

ignition

ignition

1st flame valve

opening

closing

and the 2nd flame valve

damper

damper

s

s

s

s

s

s

s

LME 22.331A2

3

30

2

2

11

12

12

LME 22.233A2

3

30

2

2

11

30

30

Summary of Contents for TBG 55

Page 2: ......

Page 75: ...75 80 000608 1041_201102...

Page 76: ...76 80 000608 1041_201102...

Page 79: ...79 80 000608 1041_201102...