33 / 69

000608042_200705

Equipment or

Safety

Preventilation

Pre-

Post

-

Opening time

time travel

time travel

programmer

time

time

ignition

ignition

1st flame valve

opening

closing

and the 2nd flame valve

damper

damper

s

s

s

s

s

s

s

LME 22.33A2

3

30

2

2

2

2

LME 22.233A2

3

30

2

2

30

30

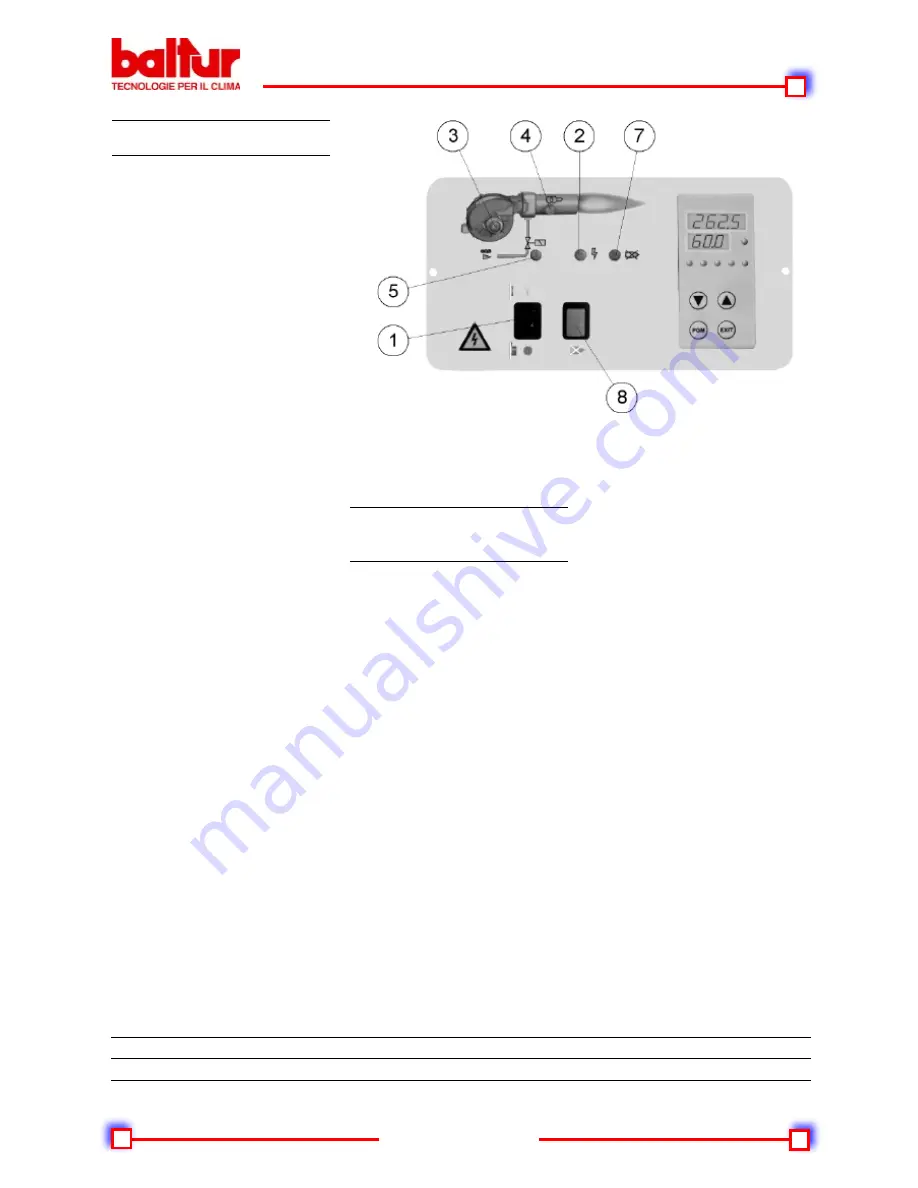

DESCRIPTION OF WORKING

Closing switch 1, if the thermostats are

closed, the voltage reaches the com-

mand and control equipment (switching

on of LED 2) which starts it working.

The fan motor is thus switched on (LED

3) to carry out the preventilation of the

combustion chamber, at the same time

the air damper control servo motor mo-

ves to the opening position correspon-

ding to the maximum regulated power.

At the end of the preventilation stage

the air damper has to be returned to the

ignition flame position. If the pressure

control switch for the ventilation air de

-

tects sufficient pressure, the ignition

transformer goes on(LED 4) and, after

two seconds, the main gas and safety

valves open (LED 5)

Note that:

a) The main valve has a device for

the proportional adjustment of the

air to gas ratio.

b) The safety valve is an ON/OFF

type.

c) The air damper is activated by an

electric servo motor (see

00029336650), remember that

when the burner is stop ped by

the thermostat, the gate damper

is brought back by the servo motor

to its closed position.

Note: The gas supply at the ignition fla

-

me position must generally be greater

than the minimum modulation capacity.

The ignition flame position can be adju

-

sted with the air damper control servo

motor. (see 0002933650).The presence

of the flame, detected by the control de

-

vice itself, permits the continuance and

completion of the ignition stage with the

switching off of the ignition transformer.

Subsequently the servo motor progres

-

sively opens the air damper and the

pneumatic valve allows the gas supply

to increase to its set maximum.

If there is no flame, the control box

stops in its “safety lock-out” (LED 7)

within 3 seconds from the opening of

the main valve. In the case of safety

lock-out the valves immediately close

again. To release the control box from

its safety position press button 8 on the

display panel.

D E S C R I P T I O N

O F

MODULATION WORKING

When the burner is running at mini

-

mum capacity, if the modulation probe

allows, (adjusted to a temperature or

pressure value greater than that in the

boiler) the air adjustment servo motor

starts to turn causing gradual increase

in combustion air supply and, conse

-

quently also of gas, up to the maxi

-

mum supply for which the burner has

been set. The increase in the fan air

pressure is detected by the proportio

-

nal gas valve sensor which gradually

adjusts gas supply to the change in air

pressure. The burner stays at maxi

-

mum delivery until the temperature or

pressure reaches a level high enough

to cause the modulation probe to turn

the air adjustment servo motor in the

opposite direction.

The backward rotation and consequent

reduction in gas and air supply happens

at brief time intervals. With this manoe

-

uvre the modulation system seeks to

balance the quantity of heat supplied

to the boiler with that which the boiler

itself provides. The modulation probe

applied to the boiler detects changes

in demand and automatically adjusts

the supply of fuel and of combustion

air, switching on the servo motor with

an increased or decreased rotation. If,

even with fuel supply at minimum, the

limit value is reached (temperature or

pressure) for which the device is set for

complete stop, (through thermostat or

pressure switch) the burner is stopped

by the device.

By lowering the temperature or pressu

-

re again below the burner stop device-

triggering figure it is switched on again

in accordance with the program descri

-

bed in the previous paragraph.