0002934691

Mod.

A

B

C

TBG 85 PN-V

5

3

3

TBG 85 P-V / PN-V

0002935021

11 / 26

0006081537_201311

ENGLISH

M o d u l a t i o n o p e r a t i o n

description

When the burner is ignited at the minimum setting, if the modulation

probe allows it (adjusted to a temperature or pressure which is

greater than that present in the boiler) the air adjustment servomotor

begins to turn causing a gradual increase in the flow of air and

consequently gas, up to the maximum flow to which the burner is set.

The increase in ventilator air pressure is detected by the proportional

gas valve sensor, which gradually adjusts the gas flow to the air

pressure variation, which is also gradual. The burner remains in

the maximum flow position until the temperature or pressure is high

enough to trip the modulation probe, which reverses the rotation of

the air adjustment servomotor.

Reverse rotation of the servomotor, and consequently a reduction in

gas and air flow, is effected in a series of short steps. By this method,

the modulation system operates to bring the amount of heat supplied

to the boiler in line with the heat that the boiler puts out to service.

The modulation probe fitted to the boiler measures any request

variations and automatically adjusts the fuel

and combustion air supply, by cutting the modulation servomotor

and increasing or reducing rotation.

during operation, the rotation speed V of the fan motor is driven by

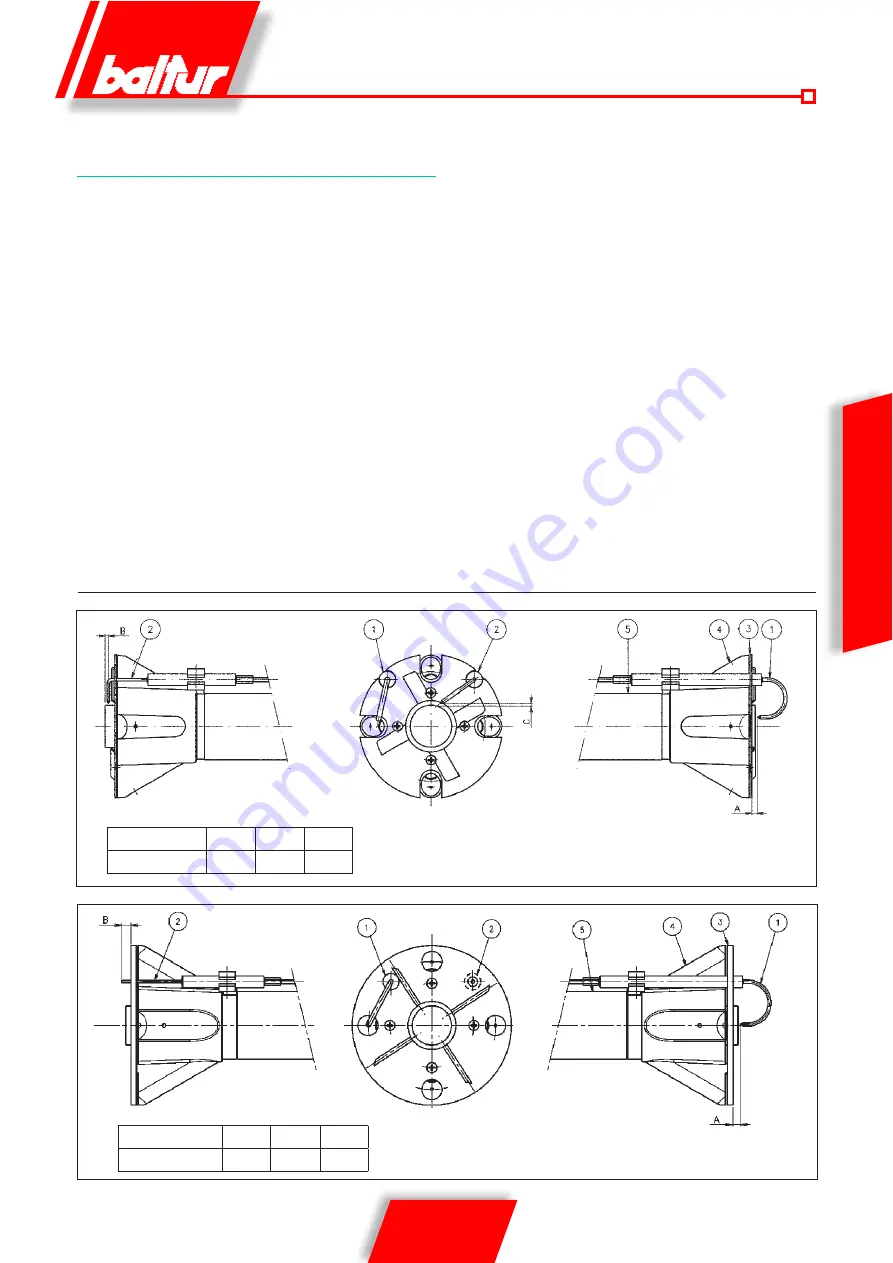

1- Ionisation electrode

2- Ignition electrode

3- Flame disk

4- Mixer

5- Gas outlet pipe

the inverter according to the air gate position. The rotation speed

V assumes an intermediate level between V1 (rotation speed

corresponding to the minimum opening) and V2 (rotation speed

corresponding to the maximum opening) and adjusts linearly

according to the rotation angle of the servomotor. If the limit value

(temperature or pressure) at which the stop device is set (thermostat

or pressure switch) is reached even with gas supply at minimum

level, the burner is shut down by the device.

When temperature or pressure drops below the shut-down device

tripping value, the burner is activated once again according to the

program described in the previous section.

Mod.

A

B

C

TBG 80 LX PN-V

5

8

-

TBG 80 LX PN-V

1- Ionisation electrode

2- Ignition electrode

3- Flame disk

4- Mixer

5- Gas outlet pipe

eLeCtroDes/ionisation ProBe aDJustment Diagram

Summary of Contents for TBG 80 LX PN V

Page 2: ......

Page 26: ...24 26 0006081537_201311 ENGLISH MINIMUM IONISATION CURRENT 3 μA OPTIONAL WIRING DIAGRAM ...

Page 28: ...26 26 0006081537_201311 ENGLISH ...

Page 54: ...26 26 0006081537_201311 ESPAÑOL ...

Page 80: ...26 26 0006081537_201311 FRANÇAIS ...

Page 104: ...24 26 0006081537_201311 TÜRKÇE ASGARİ İYONİZASYON AKIMI 3 µA TALEP ÜZERİNE ELEKTRİK ŞEMASI ...

Page 106: ...26 26 0006081537_201311 TÜRKÇE ...

Page 132: ...26 26 0006081537_201311 PYCCKИИ ...

Page 156: ...24 26 0006081537_201311 中 文 最小电离电流3μA 如果有需求 电气图 ...

Page 158: ...26 26 0006081537_201311 中 文 ...

Page 159: ......