17 / 26

0006081537_201311

ENGLISH

IGNITION AND ADJUSTMENT

• Check that combustion head penetrates the combustion

chamber by the amount requested by the manufacturer of

the boiler. Check that the device that closes the air on the

combustion head is, presumably, in the correct position to supply

the required fuel (the air passage between the disk and the

head must be greatly reduced for low combustion supply and

relatively open when combustion supply is higher). See chapter

“Combustion head adjustment”.

• It is indispensable to carry out a purge of the air contained in

the pipeline, if not done when connecting the burner to the gas

pipeline. All due precautions should be taken and doors and

windows should be opened. Open the pipe union on the pipeline

situated near the burner and then open a little the gas cut-off

cock. When the characteristic odour of gas can be smelled,

close the shut-off valve. Wait long enough for the gas in the

room to disperse, depending on local conditions, then connect

the burner to the gas pipe again.

• Check that there is water in the boiler and that the system gates

are open.

• Make absolutely sure that the products of combustion can be

released freely (boiler and chimney gate must be open).

• Make sure that the voltage of the electric line to which the

• Put the adjustment cam on the air adjustment electric servomotor

(see adjustment instructions 0002933651) in the positions which

are presumed to be appropriate in proportion to the minimum

and maximum modulation and the ignition thermal output.

• Set the desired ratio between gas and air pressure, following the

adjustment instructions of the pneumatic valve in the attached

manual for the gas train installed.

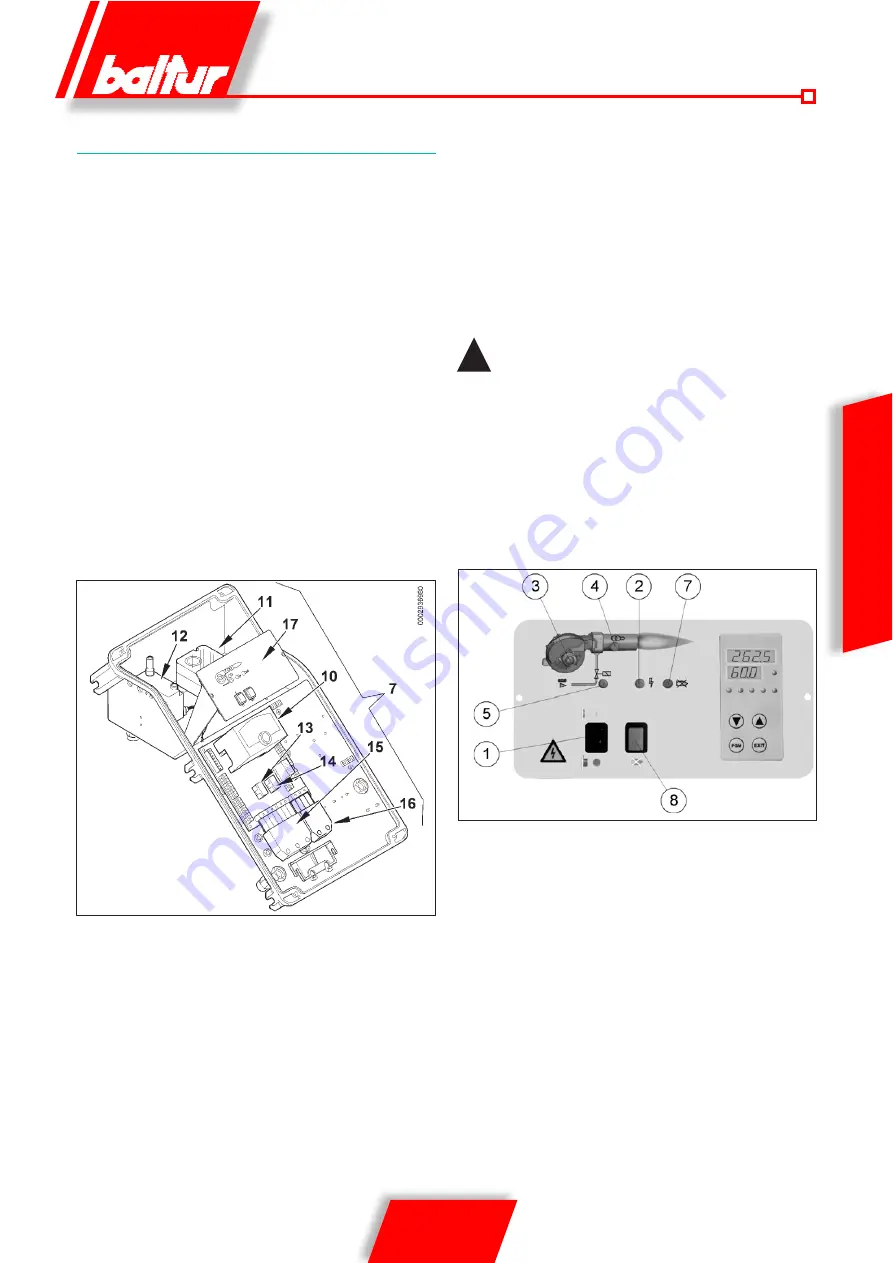

• For initial adjustment operate the burner manually using the

appropriate modulation connector supplied as standard (see

section "Instructions for manual operation of burner"). Now turn

on the I/O (1) switch on the control panel.

!

Preventilation is carried out with air open and therefore,

at the same time, the regulation servomotor is switched

on and completes the full opening stroke cycle up to

the "maximum" setting. only when the adjustment

servomotor has returned to the "ignition" position

will the control equipment proceed with its program

switching on the transformer and the ignition gas

valves.

during preventilation, make sure that the air pressure

switch changes its status (from the closed position without

pressure measurement to the closed position with pressure

burner is to be connected corresponds to that required by the

burner and that the electrical connections have been prepared

to match the voltage rating available. Check that all electrical

connections made on-site are performed correctly as shown in

our wiring diagram.

• Apply a pressure gauge of appropriate scale to the pressure

intake of gas to indicate the adjustment value (if the amount

of pressure to be used permits, it is preferable to use a water

column instrument; do not use instruments with indicator hands

for low pressures). Rotate the manual head gas pressure

adjustment device to the position which is the best with respect

to the modulation maximum thermal output and the furnace

characteristics, following the instructions laid out in the section

"Manual head gas pressure adjustment device".

measurement). If the pressure switch does not detect sufficient

pressure (and does not change status), neither the ignition

transformer nor the pilot flame gas valve are activated and the

equipment locks out. however, an occasional lock-out during the

first stage of ignition is normal, as air is still present in the valve

train pipeline. The air must be vented to obtain a stable flame.

To release, press the “reset” key (8). On first switching on

repeated “lock outs” may occur due to:

- The gas piping not being vented of the air sufficiently so that

the gas flow is insufficient to ensure a stable flame.

- “Lock out” with flame present may be caused by instability in

the ionisation area, due to an incorrect air/gas ratio. This can

be solved by changing the amount of air and/or gas supplied

so as to find the right ratio. This problem could also be caused

by a wrong air/gas distribution in the combustion head. This

can be remedied with the combustion head adjustment

device by closing or opening the air passage further between

combustion head and gas diffuser.

Summary of Contents for TBG 80 LX PN V

Page 2: ......

Page 26: ...24 26 0006081537_201311 ENGLISH MINIMUM IONISATION CURRENT 3 μA OPTIONAL WIRING DIAGRAM ...

Page 28: ...26 26 0006081537_201311 ENGLISH ...

Page 54: ...26 26 0006081537_201311 ESPAÑOL ...

Page 80: ...26 26 0006081537_201311 FRANÇAIS ...

Page 104: ...24 26 0006081537_201311 TÜRKÇE ASGARİ İYONİZASYON AKIMI 3 µA TALEP ÜZERİNE ELEKTRİK ŞEMASI ...

Page 106: ...26 26 0006081537_201311 TÜRKÇE ...

Page 132: ...26 26 0006081537_201311 PYCCKИИ ...

Page 156: ...24 26 0006081537_201311 中 文 最小电离电流3μA 如果有需求 电气图 ...

Page 158: ...26 26 0006081537_201311 中 文 ...

Page 159: ......