9 / 20

0006081531_201203

ENGLISH

ELECTRICAL CONNECTIONS

The three-phase power supply line must have a switch with fuses.

Moreover, the Standards require a switch on the burner power supply

line, placed outside the boiler room and in an easily accessible position.

For the electrical connections (line and thermostats), follow the attached

wiring diagram. To carry out the connection of the burner to the power

supply line proceed as follows:

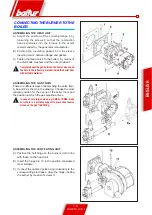

1) Remove the lid by unscrewing the 4 screws (1) in figure

1, without removing the transparent door. In this way

the burner’s electrical panel can be accessed.

2) Loosen the screws (2) and after removing the cable

clamp plate (3), make the 7 pole plug and modulation

control cable come through the hole (fig. 2). Connect

the power supply cables (4) to the radio control switch,

fix the earth cable (5) and tighten the cable gland.

3) Reposition the cable clamp plate (fig. 3). Turn the cam

(4) so that the plate exerts sufficient pressure on the

two cables, then tighten the screws that fasten the plate.

Finally connect the 7 pole plug and the modulation

control cables.

!

The housings for the cables are provided respectively

for cable Ø 9.5÷10 mm and Ø 8.5÷9 mm, this ensures the

protection rating is IP 54 (Standard IEC EN60529) for the

electrical panel.

4) To reclose the electrical panel lid, tighten the 4 screws (1) with a

tightening torque of about 5 Nm to ensure correct tightness. At this

point, to access the control panel (8), unhook the transparent door

(7), pressing gently with your hands in the direction of the arrows

shown in figure 4, slide it a short distance to separate it from the

lid.

5) To secure the transparent door on the panel properly, proceed as

indicated in figure 5: position the hooks at their hooking points (9),

slide the door in the direction indicated by the arrow until you hear

a click that ensures its seal.

!

important: only professionally qualified personnel may open

the burner electrical panel.

Fig. 2

Fig. 3

Fig. 4

Fig. 5

Fig. 1

Summary of Contents for TBG 85 ME

Page 2: ......

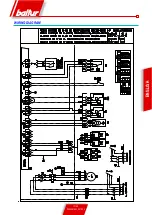

Page 19: ...17 20 0006081531_201203 ENGLISH WIRING DIAGRAM...

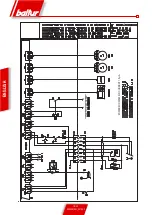

Page 20: ...18 20 0006081531_201203 ENGLISH START FOR RECORDER MINIMUM IONISATION CURRENT 1 5 A...

Page 39: ...17 20 0006081531_201203 ESPA OL ESQUEMA EL CTRICO...

Page 40: ...18 20 0006081531_201203 ESPA OL ARRANQUE PARA REGISTRADOR CORRENTE M NIMA DE IONIZACI N 1 5 A...

Page 59: ...17 20 0006081531_201203 FRAN AIS SCHEMA ELECTRIQUE...

Page 60: ...18 20 0006081531_201203 FRAN AIS MARCHE POUR ENREGISTREUR COURANT D IONISATION MINIMUM 1 5 A...

Page 79: ...17 20 0006081531_201203 T RK E ELEKTR K EMASI...

Page 80: ...18 20 0006081531_201203 T RK E REG LAT R N BA LATMA M N MUM YON ZASYON AKIMI 1 5 A...

Page 84: ...2 20 0006081531_201203 PYCCK BALTUR a b c a b c d e f g...

Page 85: ...3 20 0006081531_201203 PYCCK 2 RC a b c d e a b a b c d...

Page 89: ...7 20 0006081531_201203 PYCCK A 5 6 B 3 2 C 4 1 7 8 8a 9 DN65 DN80 A B 10 C 11...

Page 90: ...8 20 0006081531_201203 N 0002910950n2 PYCCK EN676 1 2 3 4 5 6 7 8 9 10 11 12 13 14...

Page 94: ...12 20 0006081531_201203 ioniz_BT3xx PYCCK 1 4 A 13 14 15...

Page 99: ...17 20 0006081531_201203 PYCCK...

Page 100: ...18 20 0006081531_201203 PYCCK 1 5 A...

Page 101: ...19 20 0006081531_201203 PYCCK 0 4 20 A...

Page 104: ...2 20 0006081531_201203 a b c a b c d e f g I...

Page 105: ...3 20 0006081531_201203 2 RC a b c d e a b a b c d I...

Page 109: ...7 20 0006081531_201203 5 6 2 3 7 4 1 8 8A 9 DN65 DN80 10 11...

Page 110: ...8 20 0006081531_201203 N 0002910950n2 EN676 1 2 3 4 5 6 7 8 9 10 11 12 13 14...

Page 113: ...11 20 0006081531_201203 display lamtec BT3xx 3 4 1 2 5 1 2 3 4 5 O BT3xx BT 3xx 200 CO...

Page 114: ...12 20 0006081531_201203 ioniz_BT3xx 1 4 A...

Page 117: ...15 20 0006081531_201203 figura 1 figura 2 figura 4 figura 3 2 2 1 3 4 5 8 6 8 9 0002934691 7 2...

Page 119: ...17 20 0006081531_201203...

Page 120: ...18 20 0006081531_201203 1 5 A...

Page 121: ...19 20 0006081531_201203 0 4 20 mA...

Page 123: ......